Polypropylene mixture, and preparation method and application thereof

A mixture and polypropylene technology, applied in the direction of single-component polyolefin rayon, textiles, papermaking, non-woven fabrics, etc., can solve the problems of low melt index, low grammage, impact, etc., and achieve high-speed hydrostatic pressure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0020] According to another preferred embodiment of the present invention, the method also includes adding dibenzylidene sorbitol and thiodipropionic acid di(octacyl) before, during and after the contact reaction in one or more time periods. ) ester, thereby improving the heat aging resistance of the final prepared polypropylene compound. In the method provided by the present invention, the heat aging resistance of the polypropylene mixture can be synergistically improved by adding dibenzylidene sorbitol and di(octadecyl)thiodipropionate. When only dibenzylidene sorbitol or di(octadecyl)thiodipropionate is added, the heat aging resistance of the polypropylene mixture prepared in this way will be obviously reduced. In the present invention, the addition amount of dibenzylidene sorbitol and di(octadecyl)thiodipropionate is not particularly limited. However, in order to further improve the heat aging resistance of the polypropylene mixture prepared finally, the addition of diben...

Embodiment 1

[0031] This example is used to illustrate the polypropylene compound provided by the present invention and its preparation method.

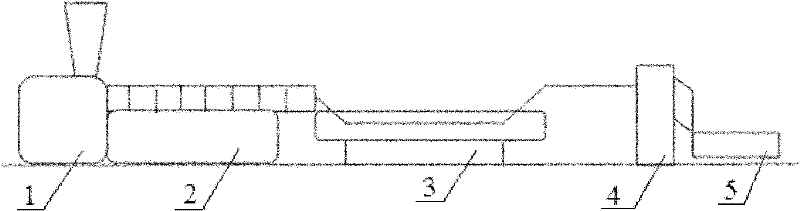

[0032] Such as figure 1As shown, 100 parts by weight of homopolypropylene (melt index is 10g / 10min, purchased from polypropylene powder 040 of Sinopec Cangzhou Branch), 0.5 parts by weight of dibenzylidene sorbitol (purchased from Beijing Daxing County Xingyu Chemical Factory), 0.5 parts by weight of di(octadecyl)thiodipropionate (purchased from Tianjin Lisheng Chemical Co., Ltd.), 0.05 parts by weight of calcium stearate (purchased from Xingyu, Daxing County, Beijing Chemical plant), 0.03 parts by weight of antioxidant 1010 (purchased from Xingyu Chemical Factory, Daxing County, Beijing, the main component is tetrakis [methyl-(3,5-di-tert-butyl-4-hydroxyphenyl) propionic acid ] pentaerythritol ester) and 0.07 parts by weight of antioxidant 168 (purchased from Xingyu Chemical Factory, Daxing County, Beijing, the main component is three (2,4-di-t...

Embodiment 2

[0038] This example is used to illustrate the polypropylene compound provided by the present invention and its preparation method.

[0039] The polypropylene mixture was prepared according to the method of Example 1, except that no dibenzylidene sorbitol was added, thereby preparing the polypropylene mixture A2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com