Microbial organic fertilizer and manufacture method of microbial organic fertilizer

A technology of bio-organic fertilizer and production method, which is applied in the preparation of organic fertilizers, the treatment of bio-organic parts, and organic fertilizers, etc., can solve the problems of substandard decomposing fermentation, poor soil improvement, and less actual utilization, etc., so as to reduce farmers' expenses, The effect of increasing farmers' economic income and preserving fruit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

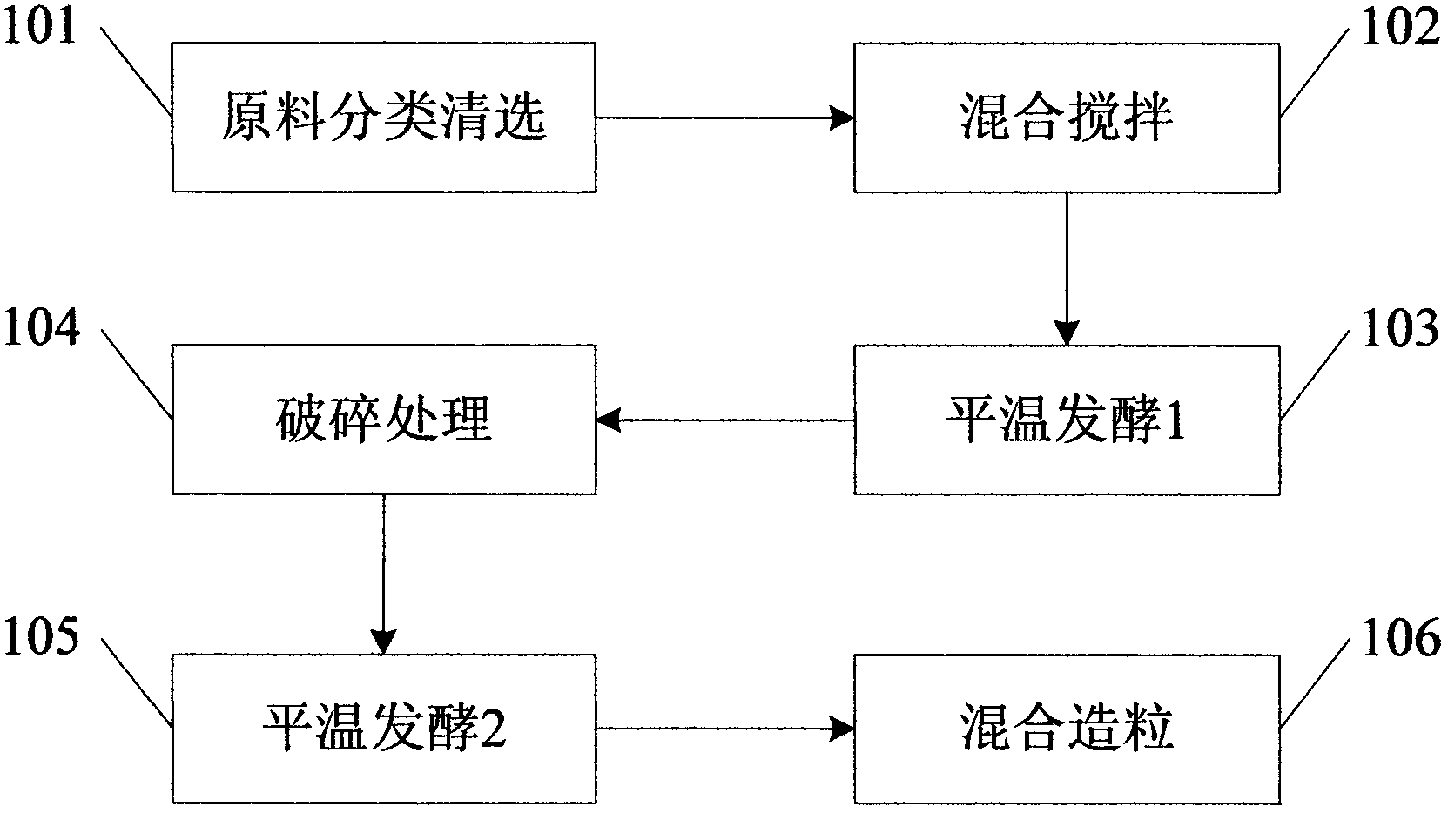

Method used

Image

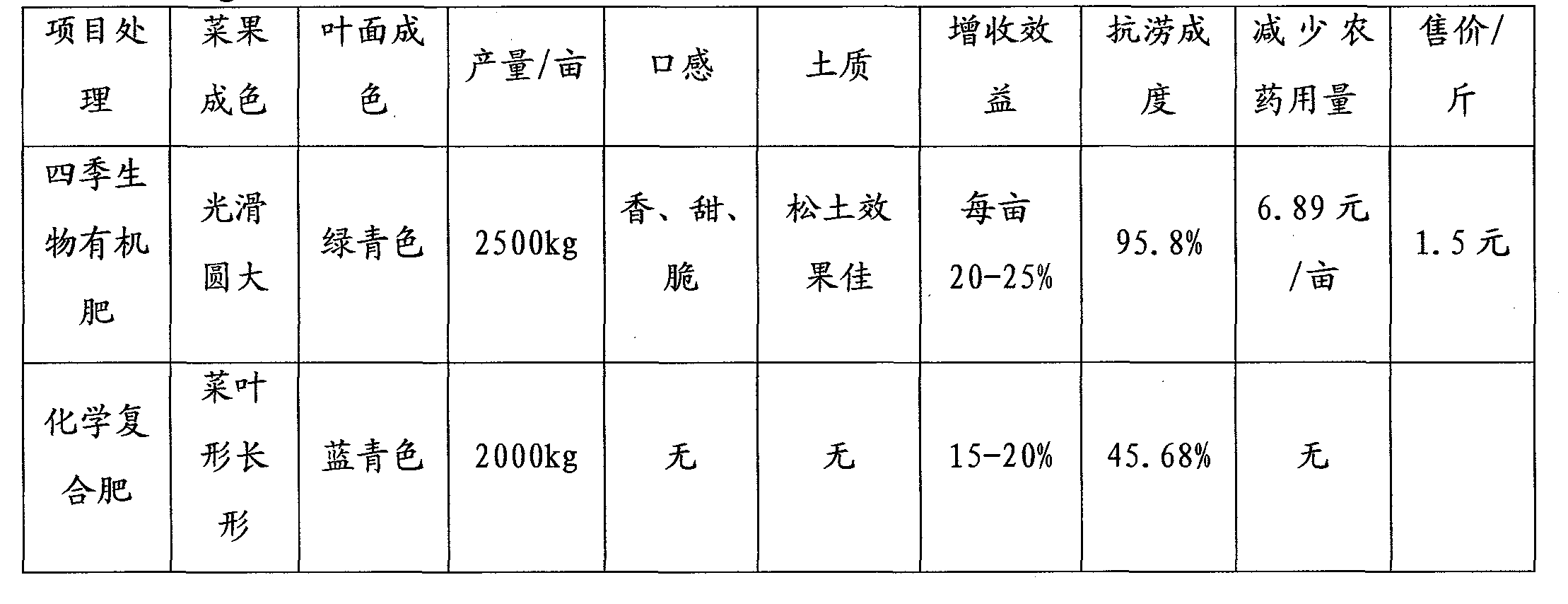

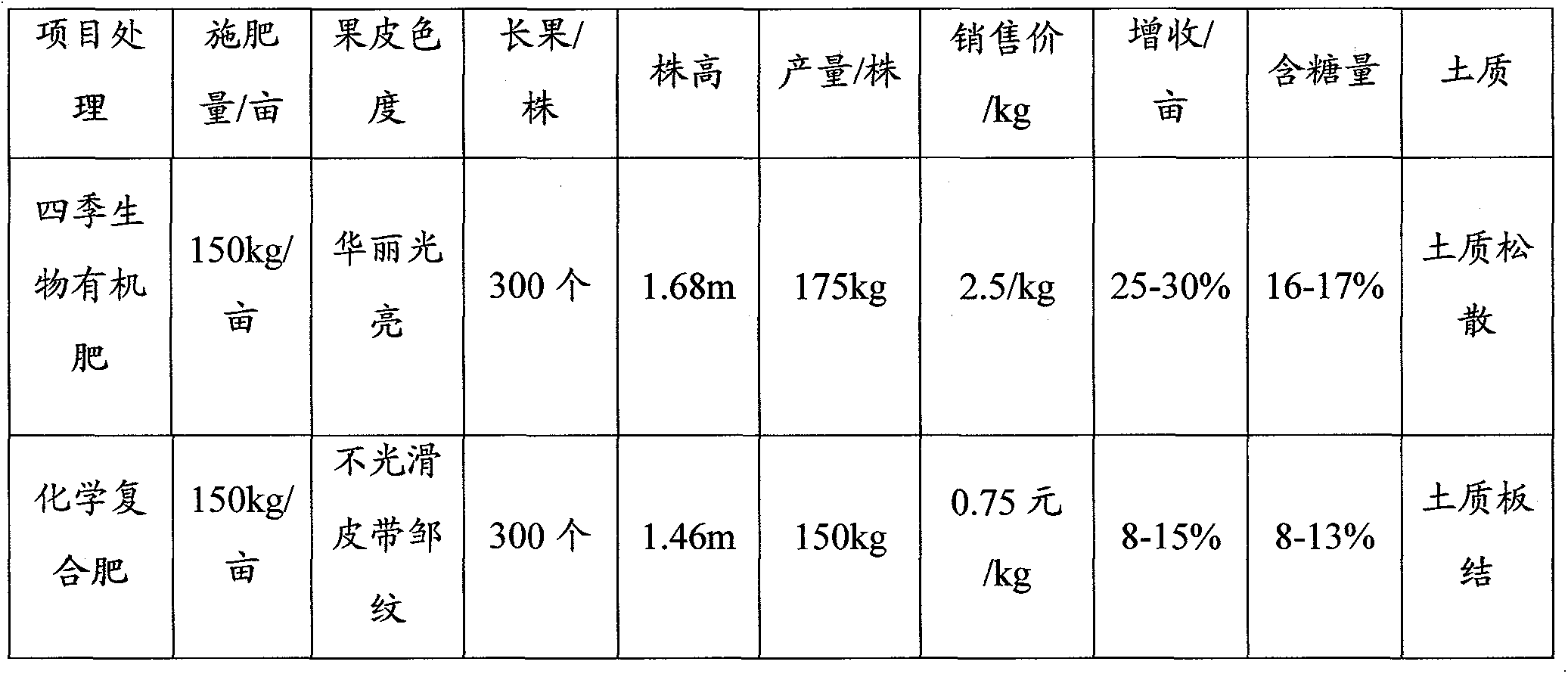

Examples

Embodiment 1

[0045] The raw materials after classification and cleaning are by raw material mass percentage livestock (cattle, sheep, horse, pig) manure 17.8%, poultry (chicken, duck, goose) manure 20%, organic matter (weathered coal) 19.89375%, house refuse 5%, 5% dry cake, 5% rice husk, straw and weeds, 2% crop stalks and 5% pyrotechnic ash are mixed, add 40% water and stir evenly with a mixer; add 0.0001% compound bacterial agent 1 according to the mass percentage of raw materials Perform flat temperature fermentation 1 treatment, keep the fermentation temperature at 50-70°C, and ferment for 8-10 days; use a crusher to crush the product after flat temperature fermentation 1; add 0.15615 % Composite bacterial agent 2 is treated with flat temperature fermentation 2, the fermentation temperature is kept at 20-45°C, and fermented for 4-5 days; the fermentation is completed when the temperature reaches below 25%, and the moisture is below 20%; the product after flat temperature fermentation 2...

Embodiment 2

[0050] The raw materials after classification and cleaning are 25% by mass percentage of livestock (cattle, sheep, horse, pig) excrement, 20% of poultry (chicken, duck, goose) excrement, 20% of organic matter (brown coal), 5% of household garbage, dry 9.7375% cake, 5% chaff, straw and weeds and 2% crop stalks are mixed, 40% water is added and stirred evenly with a mixer; Keep the fermentation temperature at 50-70°C and ferment for 8-10 days; use a crusher to crush the product after flat temperature fermentation 1; add 0.1624% composite bacterial agent 2 to the crushed product according to the mass percentage of raw materials Warm fermentation 2 treatment, the fermentation temperature is maintained at 20-45 ° C, and fermentation is carried out for 4-5 days; the temperature reaches below 25%, and the fermentation is completed when the moisture is below 20%; to the product after the flat temperature fermentation 2 treatment, add 5 % nitrogen fertilizer, 5% phosphate fertilizer, 3...

Embodiment 3

[0055] The raw materials after classification and cleaning are by raw material mass percentage livestock (cattle, sheep, horse, pig) excrement 27.7%, poultry (chicken, duck, goose) excrement 5%, organic matter (weathered coal) 20%, withered cake 5%, 5% of leaves, 5% of chaff, rice straw and weeds, 2% of crop straw and 5% of fire ash are mixed, and 40% of water is added and stirred evenly with a mixer; 0.0001% of compound bacterial agent 1 is added according to the mass percentage of raw materials Flat-temperature fermentation 1 treatment, the fermentation temperature is kept at 50-70°C, and fermentation is carried out for 8-10 days; the product after flat-temperature fermentation 1 is crushed with a crusher; the crushed product is added 0.15615% according to the mass percentage of raw materials Composite bacterial agent 2 is treated with flat temperature fermentation 2, the fermentation temperature is kept at 20-45°C, and fermented for 4-5 days; the fermentation is completed wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com