Composite medicinal preparation for biochemical effluent deep treatment of sewage plant

A composite agent and biochemical water effluent technology, which is applied in water/sewage treatment, adsorption water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems that the ingredients cannot work together quickly and effectively, and the treatment effect of the agent is limited. Achieve remarkable sweeping effect, improve the effect of flocculation and sedimentation, and improve the effect of adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

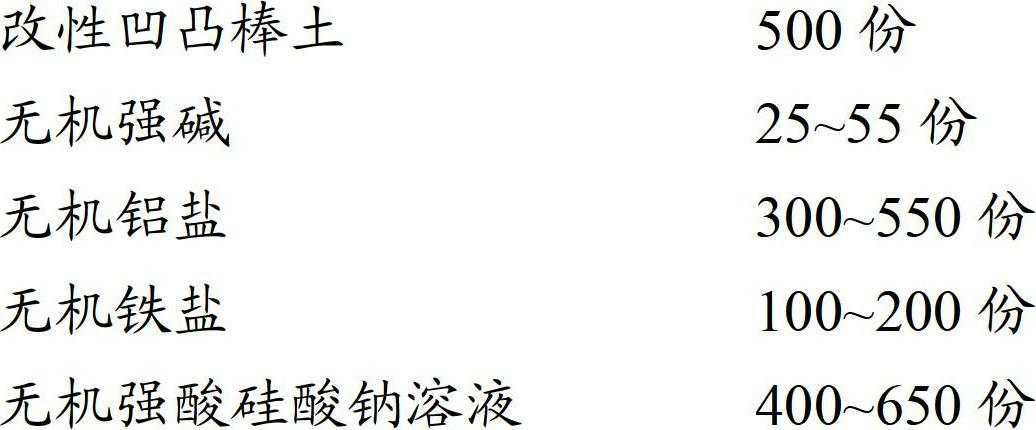

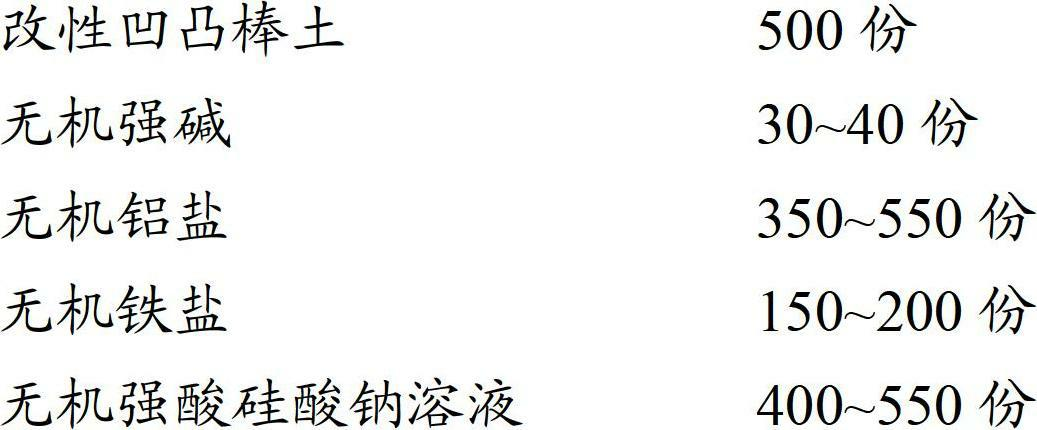

[0052] The preparation of a compound agent suitable for the advanced treatment of biochemical effluent from sewage plants comprises the following preparation steps:

[0053] (1) Weigh 500g of attapulgite, then add 500g of 6mol / L hydrochloric acid solution, fully soak the attapulgite and seal it for 24 hours, then wash it with water several times until the pH of the washing liquid is close to 7, then dry it at 105°C, bake After drying, cool and grind to a fineness of 100 mesh to obtain hydrochloric acid modified attapulgite powder.

[0054] (2) Weigh 150g Na 2 SiO 3 9H 2 O, dissolved in 150g of water to obtain a 50% mass fraction sodium silicate solution, take 200g of a 15% hydrochloric acid solution (containing 30g of HCl). Take 200 g of the above 50% sodium silicate solution and put it in a container, slowly add 15% hydrochloric acid solution while stirring, wait until it is evenly mixed, let stand and mature for 24 hours to obtain sodium silicate hydrochloride solution. ...

Embodiment 2

[0061] A method for preparing a functional compound agent for advanced treatment in sewage plants, comprising the following preparation steps:

[0062] (1) Weigh 500g of magnesium aluminum silicate mineral attapulgite, then add 750g of an appropriate amount of 3mol / L sulfuric acid solution, fully soak the attapulgite and seal it for 24 hours, then wash it with water several times until the pH of the washing solution is close to 7, then Dried at 105°C, cooled after drying, and ground to a fineness of 100 mesh to obtain hydrochloric acid modified attapulgite powder.

[0063] (2) Weigh 150g of sodium silicate, dissolve it in 150g of water to obtain a 50% sodium silicate solution, and take 200g of a 10% hydrochloric acid solution (containing 20g of HCl). Take 200g of 50% sodium silicate solution and put it in a container, slowly add 10% sulfuric acid solution while stirring, wait until it is evenly mixed and leave it to mature for 24 hours to obtain sodium silicate hydrochloride s...

Embodiment 3

[0070] The preparation of a compound agent suitable for the advanced treatment of biochemical effluent from sewage plants comprises the following preparation steps:

[0071](1) Weigh 400g of attapulgite, then add 250g of 6mol / L hydrochloric acid solution, fully soak the attapulgite and seal it for 24 hours, then wash it with water several times until the pH of the washing solution is close to 7, then dry it at 105°C, bake After drying, cool and grind to a fineness of 100 mesh to obtain hydrochloric acid modified attapulgite powder.

[0072] (2) Weigh 165g Na 2 SiO 3 9H 2 O, dissolved in 135g of water to obtain a 55% mass fraction sodium silicate solution, take 250g of a 10% hydrochloric acid solution (containing 25g of HCl). Take 200 g of the above 50% sodium silicate solution and put it in a container, slowly add 10% hydrochloric acid solution while stirring, wait until it is evenly mixed and leave it to mature for 24 hours to obtain sodium silicate hydrochloride solution....

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

| decolorization rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com