Multilayer dislocation punching device

A punching device and punching needle technology, which is applied in packaging and other directions, can solve the problems of dust pollution on the filling site, and achieve the effects of avoiding waste, increasing filling speed, and avoiding material waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] A preferred embodiment will be given below, and the present invention will be described more clearly and completely in conjunction with the accompanying drawings.

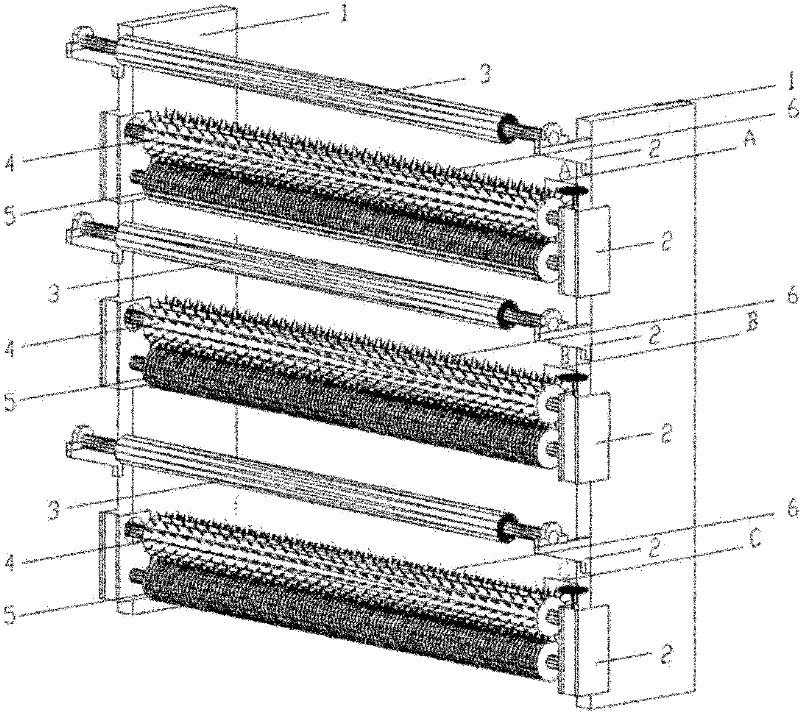

[0010] Such as figure 1 As shown, the multi-layer dislocation punching device of the present invention includes a wall panel 1, a bearing mounting seat 2, a paper roller 3, a needle roller 4, a rubber idler roller 5 and a perforating needle 6, and a bearing is installed on the wall panel 1. The mounting base 2, the paper passing roller 3 is installed on the bearing mounting base 2, the needle roller 4 is also installed on the bearing mounting base 2, the rubber idler 5 paired with the needle roller 4 is installed on the bearing mounting base 2 in pairs with the needle roller 4 On, perforating pin 6 is installed above needle roller 4, and the length of perforating pin 6 is 2 to 8 millimeters, preferably 5 millimeters. When the needle roller 4 and the rubber idler 5 rotate in opposite directions and entrain t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com