Method, device and system for controlling material supplement and packager

A feeding control and feeding technology, applied in the field of feeding, can solve the problem of difficulty in ensuring the discharge efficiency of the material silo, and achieve the effect of ensuring the pressurization effect and the discharging efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

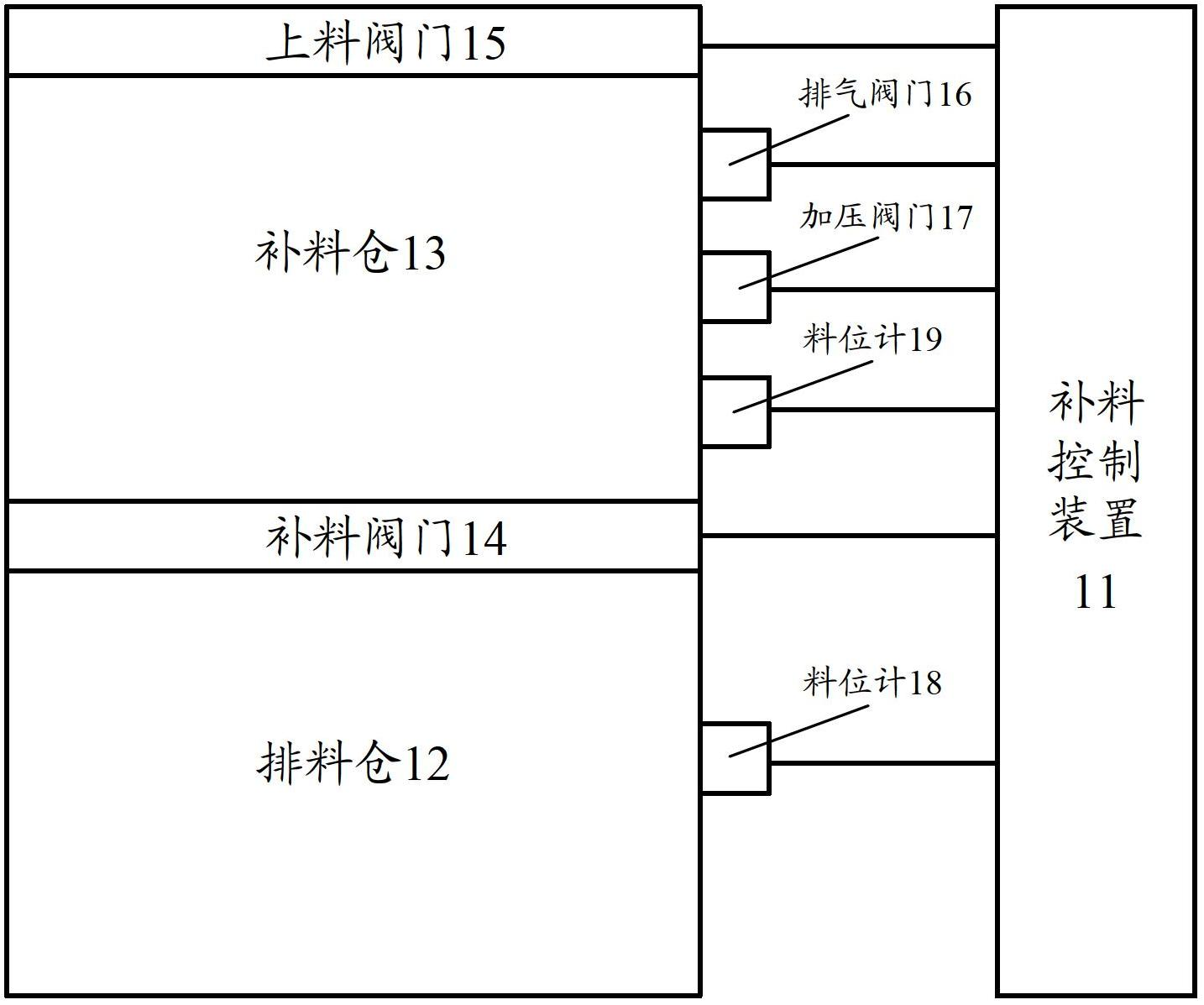

[0019] Such as figure 1 As shown, it is a schematic structural diagram of the feeding control system proposed in Embodiment 1 of the present invention. The system includes a material bin and a feeding control device 11. The material bin includes a discharge bin 12 and a feeding bin 13. A feed valve 14 is arranged between the bins 13. When the feed valve 14 is closed, the discharge bin 12 is a closed space, and the discharge bin 12 can discharge the materials therein.

[0020] The feeding bin 13 is also provided with a feeding valve 15. When the feeding valve 15 is closed and the feeding valve 14 is closed, the discharging bin 12 and the feeding bin 13 are respectively a closed space, and the discharging bin 12 can carry out normal operation. discharge operation; when the feeding valve 15 is closed and the feed valve 14 is opened, the discharge bin 12 and the feed bin 13 form an integral material bin, and the material bin is a closed space at this time. The feeding bin 13 feed...

Embodiment 2

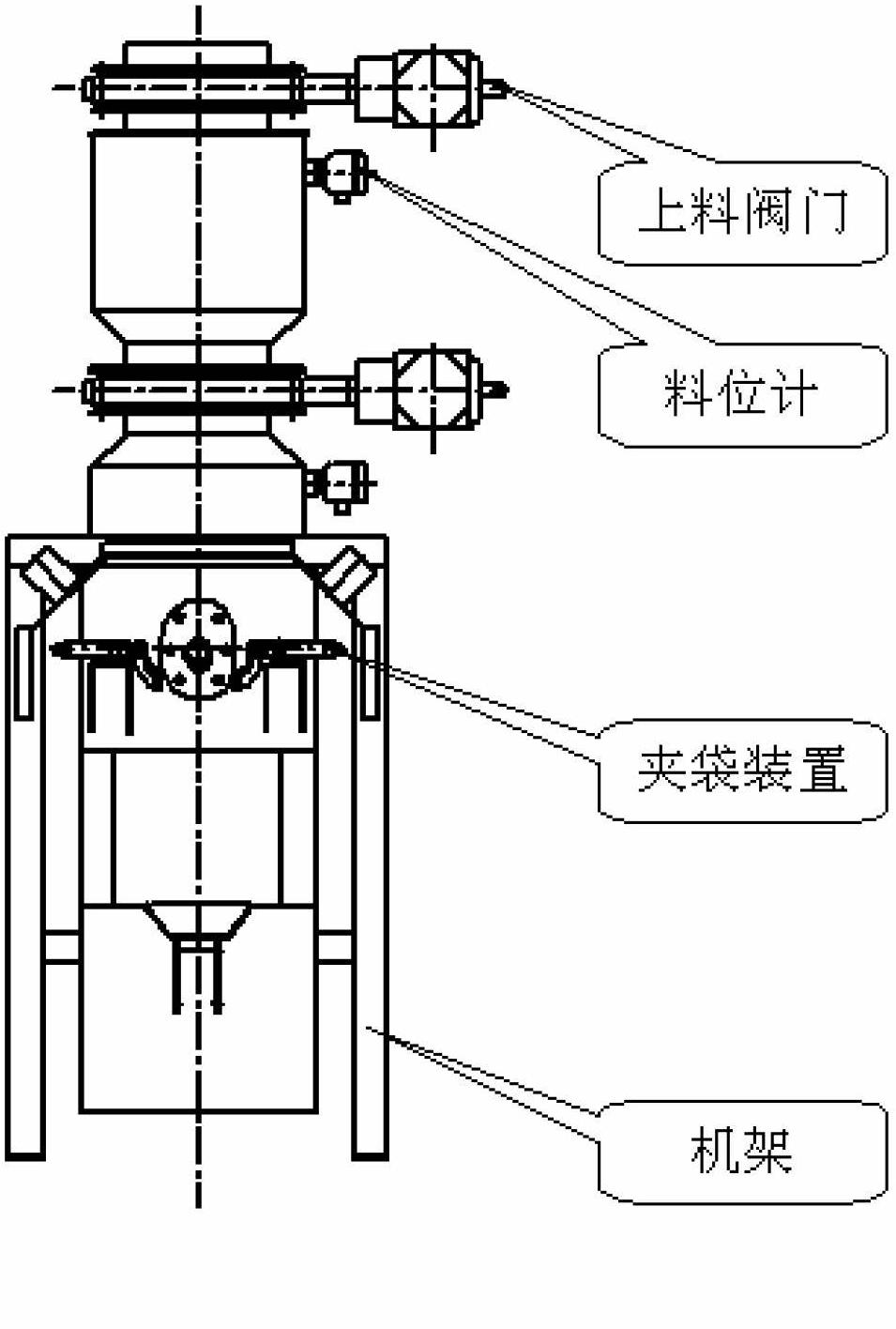

[0037] The feeding control system proposed in Embodiment 1 of the present invention can be applied in packaging machines, but not limited to, and can also be applied in other equipment equipped with material bins. Therefore, Embodiment 2 of the present invention proposes a packaging machine, at least including the feeding control system proposed in Embodiment 1 of the present invention.

[0038] The feeding control system proposed in Embodiment 1 of the present invention can be applied to a packaging machine for packaging granular materials or powdery materials.

Embodiment 3

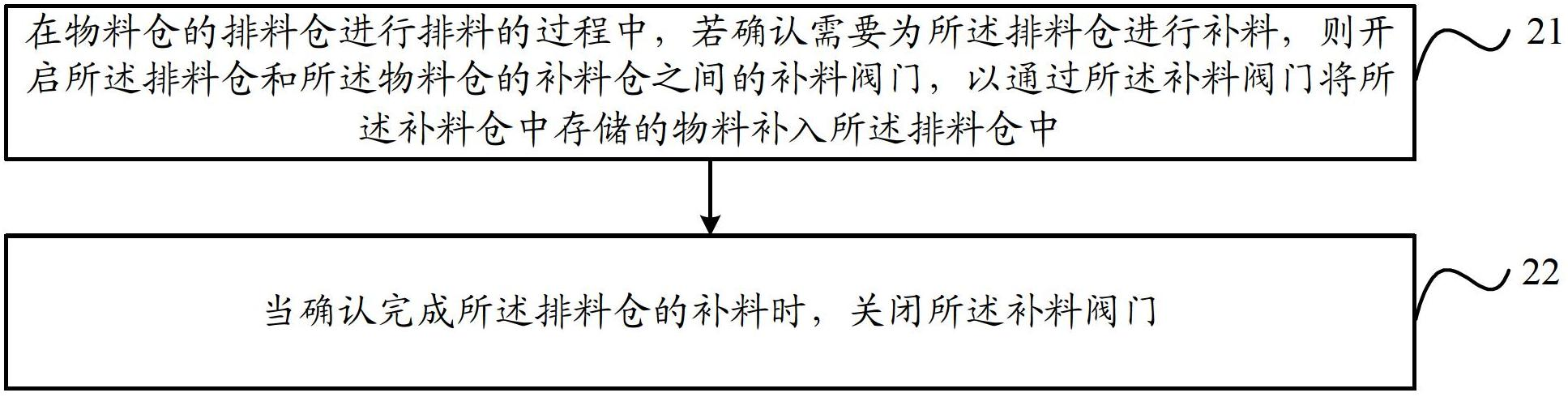

[0040] Based on the feeding control system proposed in Embodiment 1 of the present invention, Embodiment 3 of the present invention proposes a feeding control method, such as figure 2 As shown, the specific processing flow is as follows:

[0041] Step 21, during the discharge process of the discharge bin of the material bin, if it is confirmed that it is necessary to replenish the material for the discharge bin, start the replenishment between the discharge bin and the replenishment bin of the material bin. feed valve, so that the materials stored in the feed bin can be replenished into the discharge bin through the feed valve.

[0042] Wherein, the manner of confirming the need to replenish the discharge bin may include, but is not limited to, the following two types:

[0043] The first way is to receive the height value of the material in the discharge bin detected and sent by the material level gauge in the discharge bin, and then judge whether the received height value i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com