Preparation method for core-shell structural nickel-silver bimetallic powder

A technology of metal powder and shell structure, applied in the direction of coating, etc., can solve the problems of unfavorable product performance stability and production cost, reduction, complicated process, etc., and achieve the effect that is beneficial to product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

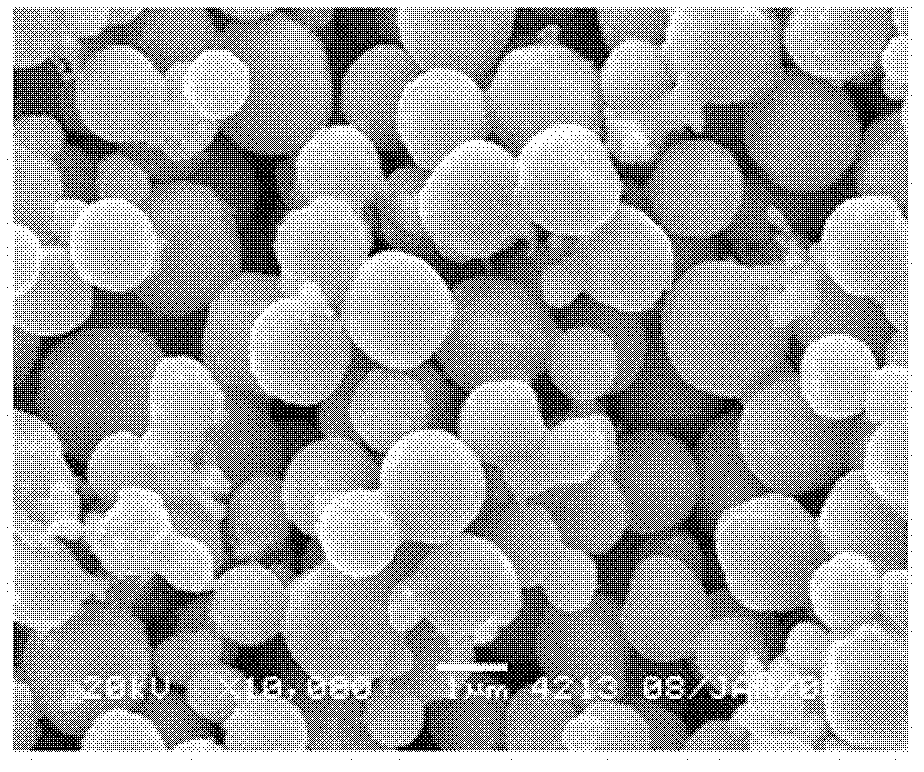

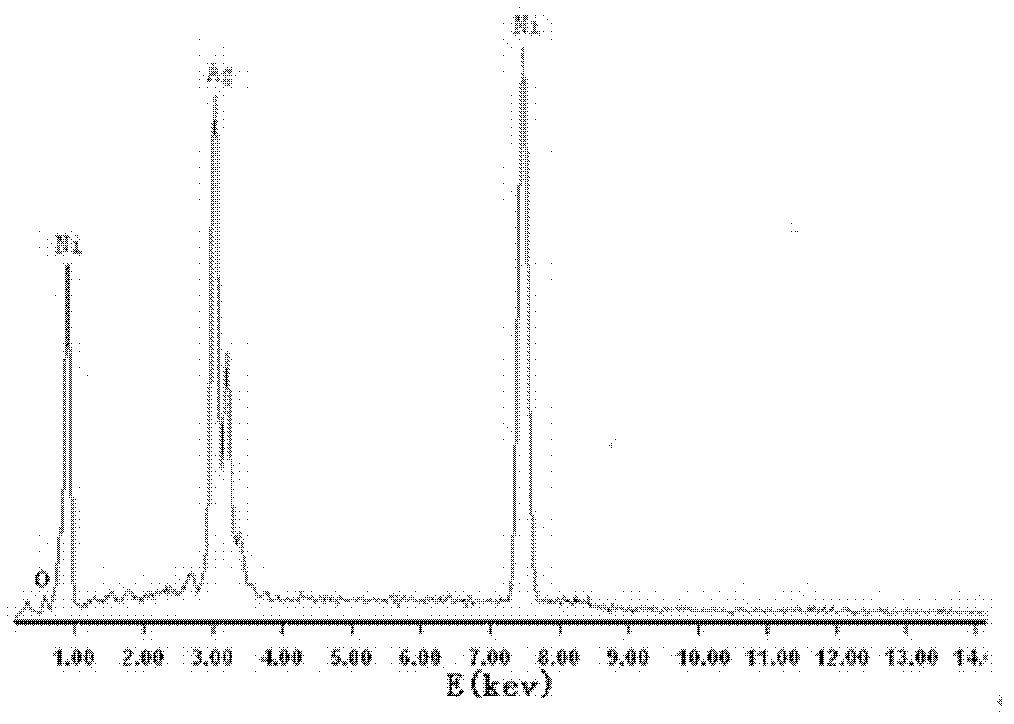

[0023] The preparation method of the core-shell structure nickel-silver bimetallic powder in this embodiment comprises the following steps:

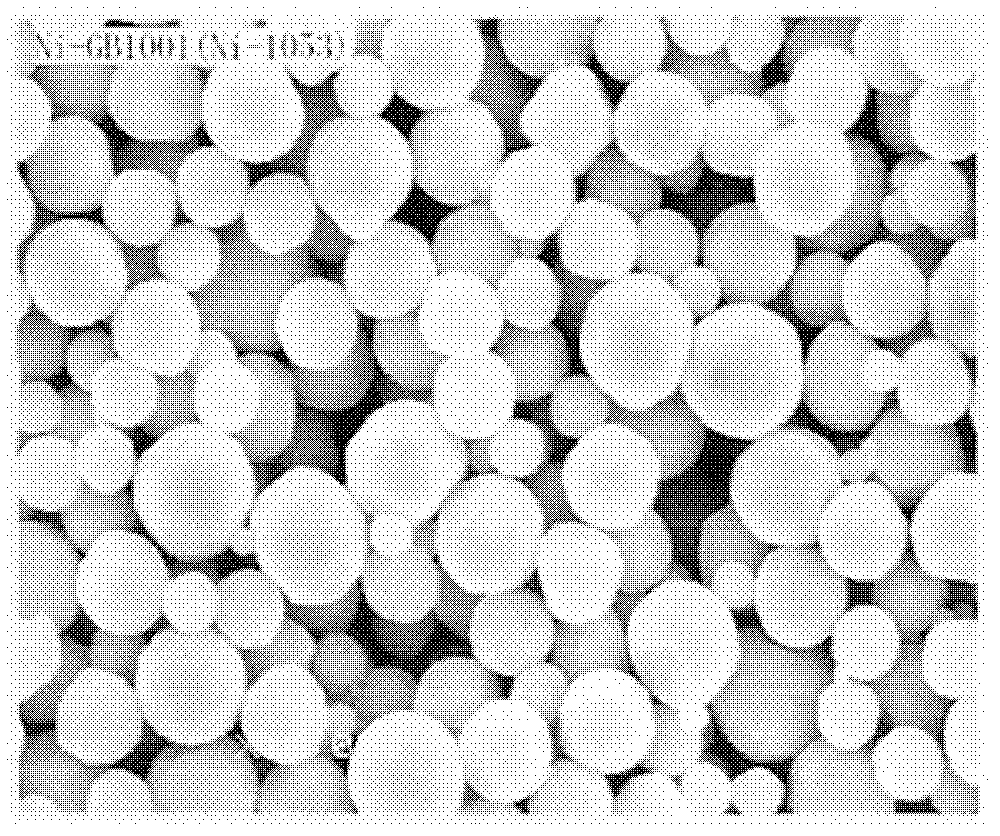

[0024] (1) Add 25g of nickel powder and 8.33g of dispersant PVP into 1L of ethanol-water mixed solvent, then place it in a water bath, keep the temperature of the water bath at 50°C, stir for 1 hour at a stirring speed of 500rpm, and obtain a nickel powder dispersion Solution, wherein the nickel powder is composed of spherical nickel particles with an average particle diameter of 1.0 μm, and the volume ratio of ethanol and water in the ethanol-water mixed solvent is: ethanol: water=2: 5;

[0025] (2) mixing the reducing agent hydrazine hydrate with water to obtain a hydrazine hydrate aqueous solution with a hydrazine hydrate concentration of 2.5mol / L, adjusting the pH value of the hydrazine hydrate aqueous solution to 11 to obtain a reducing agent solution;

[0026] (3) Nickel powder dispersion solution and reducing agent solution are mi...

Embodiment 2

[0033] The preparation method of the core-shell structure nickel-silver bimetallic powder in this embodiment comprises the following steps:

[0034] (1) Add 25g of nickel powder and 8.33g of dispersant sodium tartrate into 1L of ethanol-water mixed solvent, then place it in a water bath, keep the temperature of the water bath at 50°C, stir for 1 hour, and the stirring speed is 500rpm to obtain nickel powder Dispersion solution, wherein the nickel powder is composed of spherical nickel particles with an average particle diameter of 1.0 μm, and the volume ratio of ethanol and water in the ethanol-water mixed solvent is: ethanol: water=2:5;

[0035] (2) mixing the reducing agent hydrazine hydrate with water to obtain a hydrazine hydrate aqueous solution with a hydrazine hydrate concentration of 2.5 mol / L, and adjusting the pH value of the hydrazine hydrate aqueous solution to 12 to obtain a reducing agent solution;

[0036] (3) Nickel powder dispersion solution and reducing agent s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com