Preparation method for microspherical nano CaO-based CO2 adsorber for circulating fluidized bed, product and application

A circulating fluidized bed and adsorbent technology, applied in chemical instruments and methods, through adsorption, separation methods, etc., can solve the problems of easy attenuation of adsorption capacity, easy wear of adsorbent, and unsolved adsorption capacity, etc., to achieve excellent mass transfer , Lower adsorption reaction temperature, excellent adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

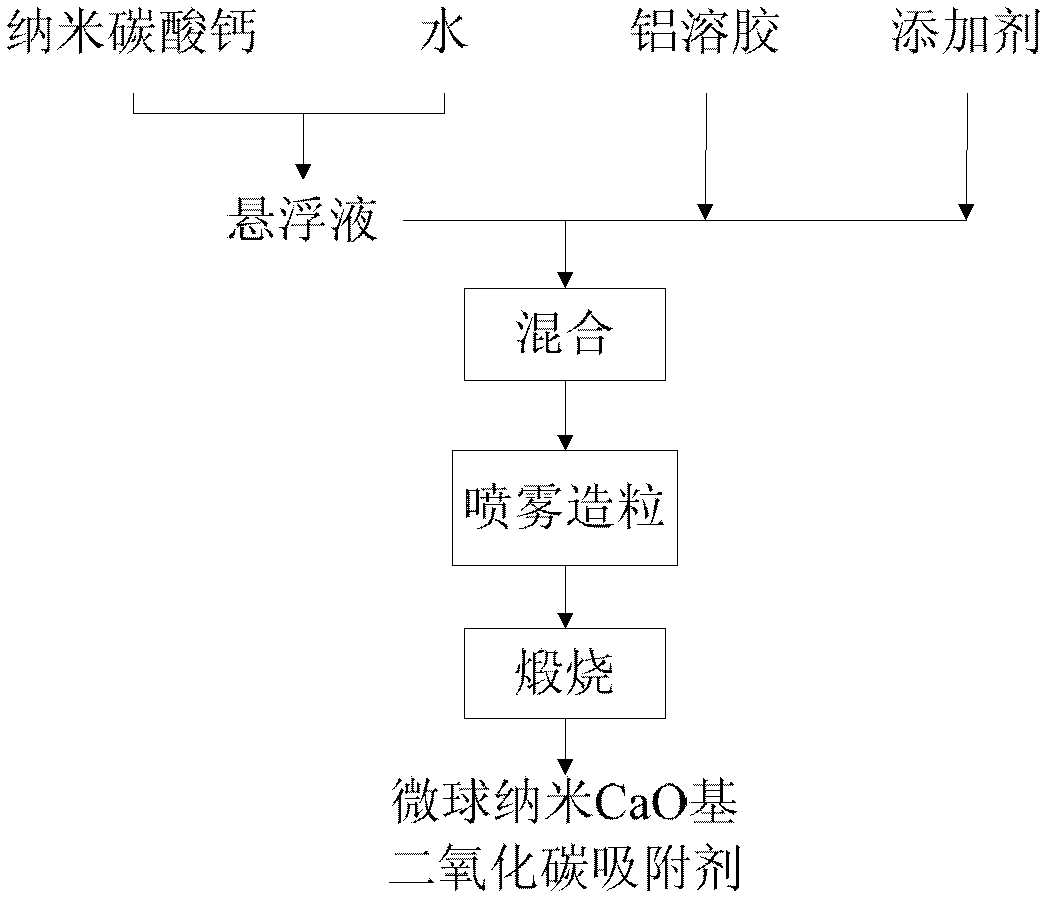

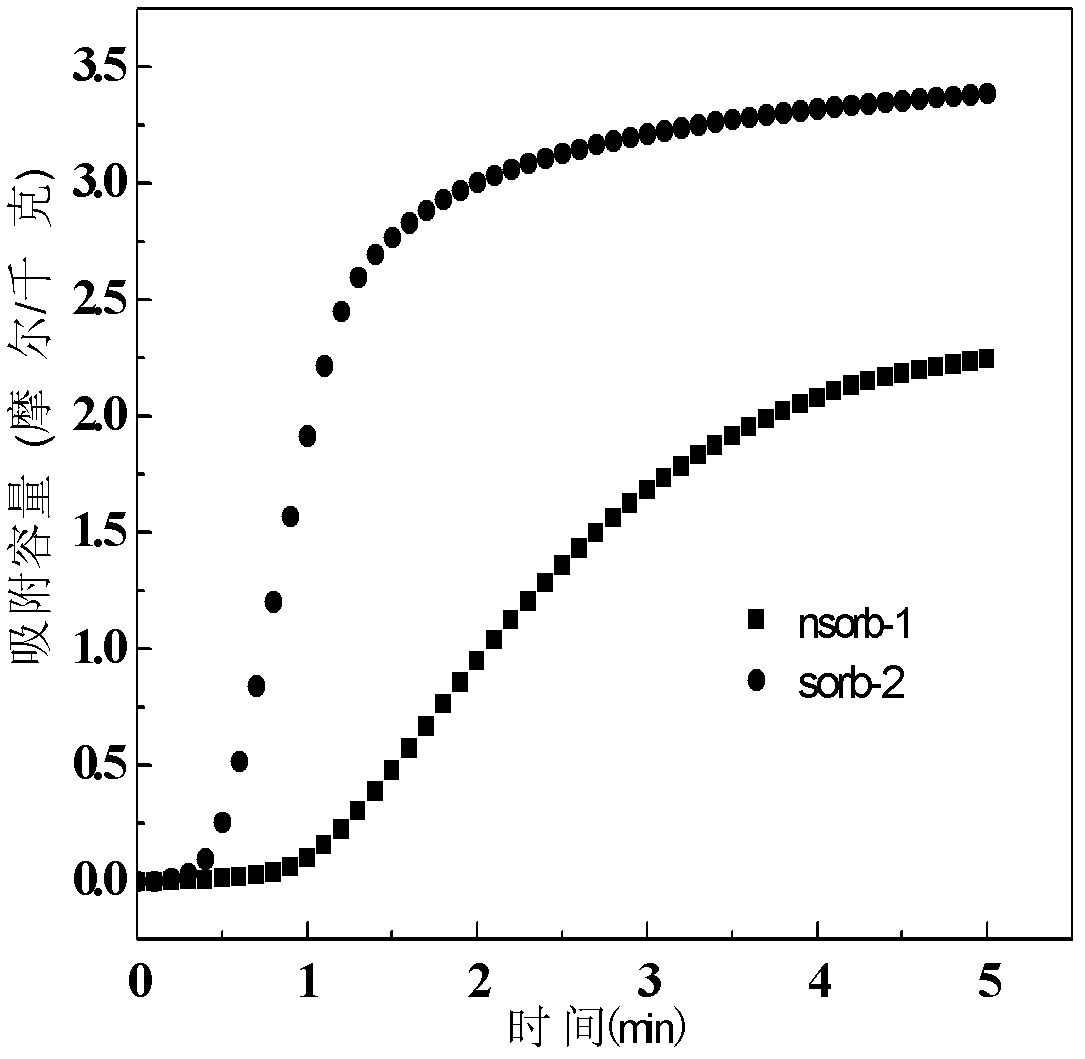

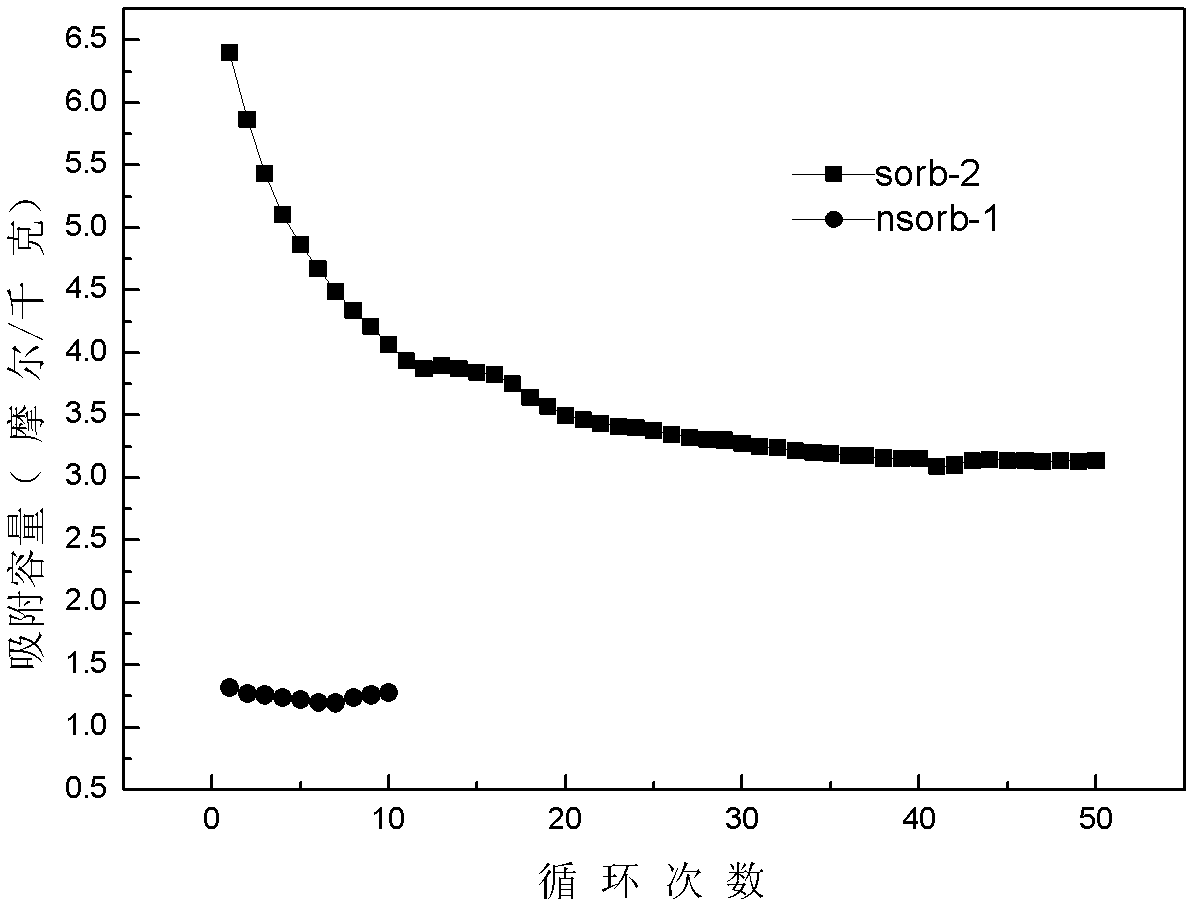

[0052] Example 1 Microsphere Nano CaO-based CO 2 Sorbent preparation

[0053] nanoCaCO 3 10g is dispersed in 50ml distilled water to form a uniformly dispersed suspension, and the nano-CaCO 3 51g of aluminum sol with a mass fraction of 20% and 1.5g of ammonium aluminum carbonate were added to the suspension, and mixed thoroughly to form a uniform slurry. The slurry was spray granulated to obtain solid adsorbent particles with a particle size of 20 microns. The adsorbent particles were calcined at 880 °C for 1 h to obtain microsphere nano-CaO-based CO 2 Adsorbent, sorb-2.

[0054] The microsphere nano-CaO base CO prepared in this embodiment 2 The sorbent particle attrition rate was 4.0%.

Embodiment 2

[0055] Example 2 Microsphere Nano CaO-based CO 2 Sorbent preparation

[0056] nanoCaCO 3 20g is dispersed in 160ml distilled water to form a uniformly dispersed suspension, and the nano-CaCO 3 8.16g of aluminum sol with a mass fraction of 5% and 4g of polyethylene glycol were added to the suspension, and mixed thoroughly to form a uniform slurry. The slurry is sprayed and granulated to obtain solid adsorbent particles with a particle size of 200 microns. The adsorbent particles were calcined at 1000 °C for 4 h to obtain microsphere nano-CaO-based CO 2 Adsorbent, sorb-3.

[0057] The microsphere nano-CaO base CO prepared in this embodiment 2 The sorbent particle attrition rate was 3.3%.

Embodiment 3

[0058] Example 3 Microsphere Nano CaO-based CO 2 Sorbent preparation

[0059] nanoCaCO 3 20g is dispersed in 100ml distilled water to form a uniformly dispersed suspension, and the nano-CaCO 3 20.4 g of aluminum sol with a mass fraction of 10% and 0.1 g of polyethylene glycol 2000 were added to the suspension, and mixed thoroughly to form a uniform slurry. The slurry was sprayed and granulated to obtain solid adsorbent particles with a particle size of 60 microns. The adsorbent particles were calcined at 850 °C for 2 h to obtain microsphere nano-CaO-based CO 2 Adsorbent, sorb-4.

[0060] The microsphere nano-CaO base CO prepared in this embodiment 2 The sorbent particle attrition rate was 5.0%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com