Water body heater for aquarium creature culture and pet feeding

A technology for heaters and water bodies, applied in water heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of glass or ceramic tubes that are easily broken, low heat conduction efficiency, and limited use occasions, and achieve environmental protection Lightweight, avoid easy breakage, and increase the effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

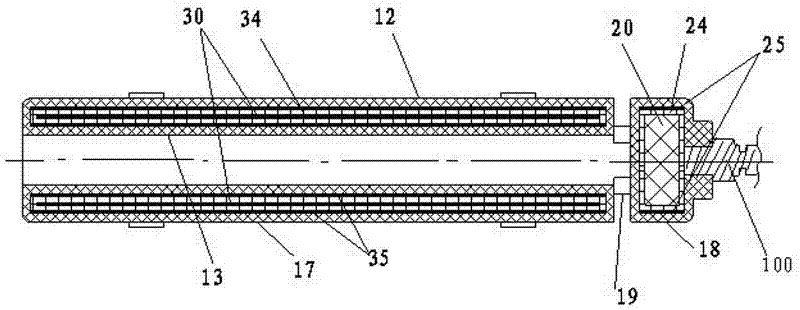

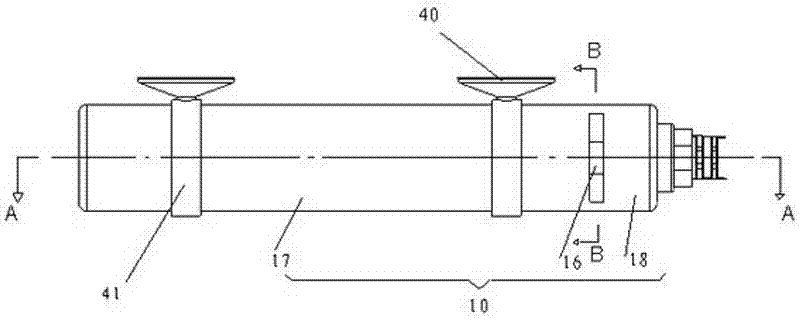

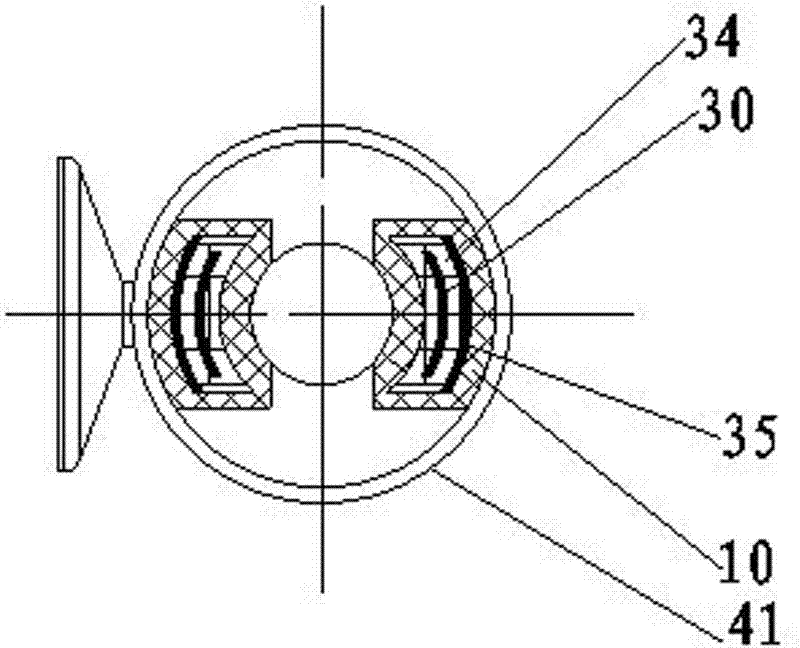

[0033] refer to Figure 1 to Figure 4 As shown, the housing 10 is a tubular body, including a first section of double-walled tubular body 17 for accommodating a heating element 30 and a second section of tubular body 18 with a built-in temperature control circuit assembly 20; in the first section of tubular body 17 The connecting section 19 between the second section of the tubular body 18 is provided with a radial channel 16, and the channel 16 communicates with the axial central cavity of the first section of the double-walled tubular body 17; the axial central cavity The cylindrical wall surface of the inner ring is the second heat exchange surface 13 , and the wall surface of the channel 16 is a part of the second heat exchange surface 13 .

[0034] The tubular casing includes two nested inner tubes and outer tubes, and has an annular bottom cover. The outer wall of the inner tube, the inner wall of the outer tube and the annular bottom cover form a sandwich container for...

no. 2 example

[0038] refer to Figure 5 to Figure 7 As shown, the shell 60 is in the shape of a hollow plate, and the front and rear sides of the plate-shaped shell 60 are respectively the first heat exchange surface 62 and the second heat exchange surface 63 .

[0039] The heating element 80 has a plate shape adapted to the cavity shape of the housing 60 . The heating element is in the shape of a flexible plate.

[0040] The heat conduction layer 85 is also a sheet-shaped aluminum or copper material adapted to the shape of the cavity of the plate-shaped casing 60 .

[0041] Between the heating body 80 and the heat conduction layer 85, an insulating layer 84 with two sides respectively attached to the heat generation body 80 and the heat conduction layer 85 is provided, and an insulating layer 84 is provided between the temperature control circuit assembly 70 and the heat conduction layer 85. An insulating layer 74 is also arranged between the layers 75, and its two sides are respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com