Carbon-loaded kernel-shell copper-palladium-platinum catalyst for fuel battery and preparation method thereof

A fuel cell and platinum catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of reduced catalytic efficiency, large catalyst particle size, shedding, etc. problem, to achieve the effect of strengthening combination, improving effect and promoting development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

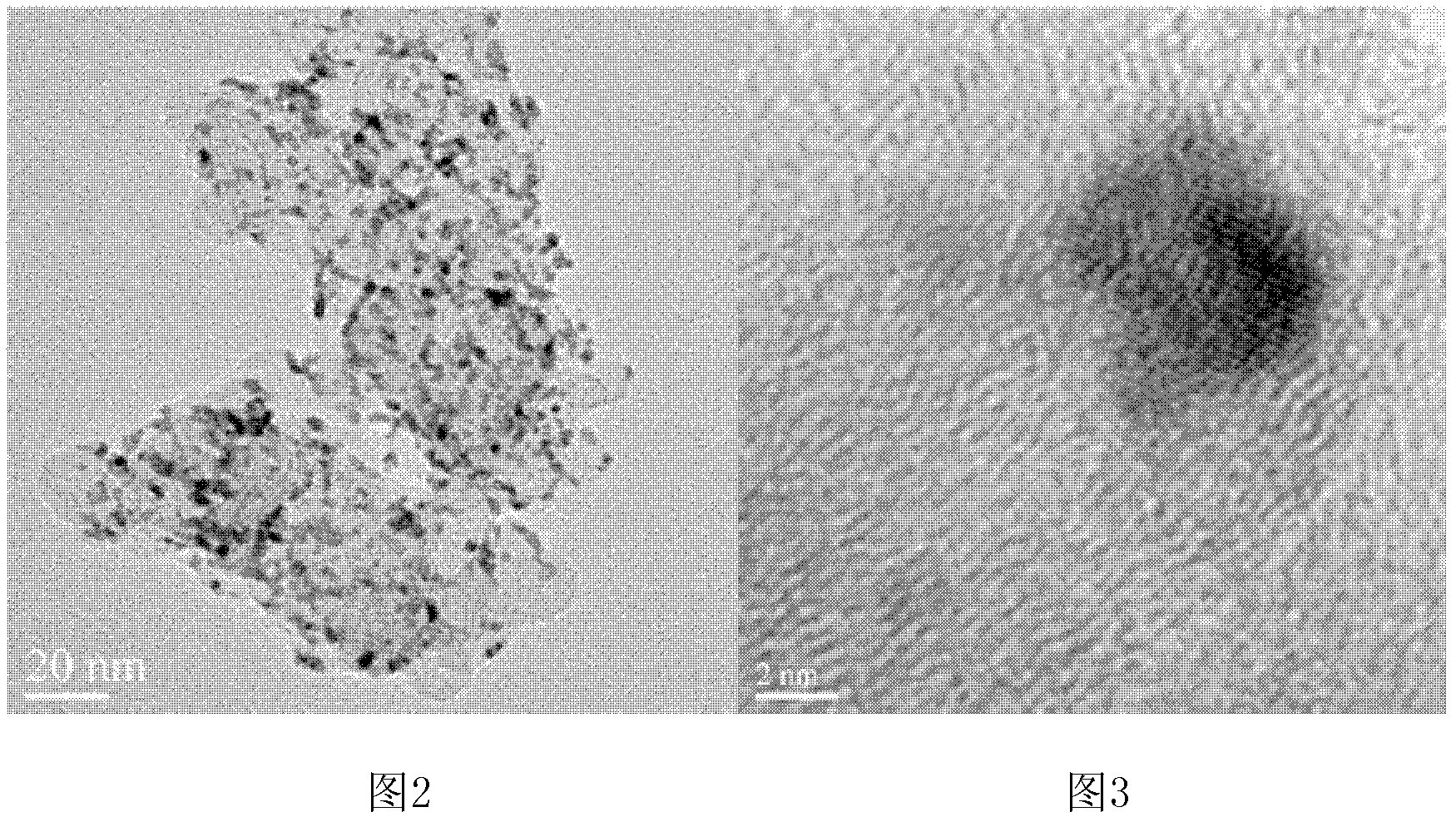

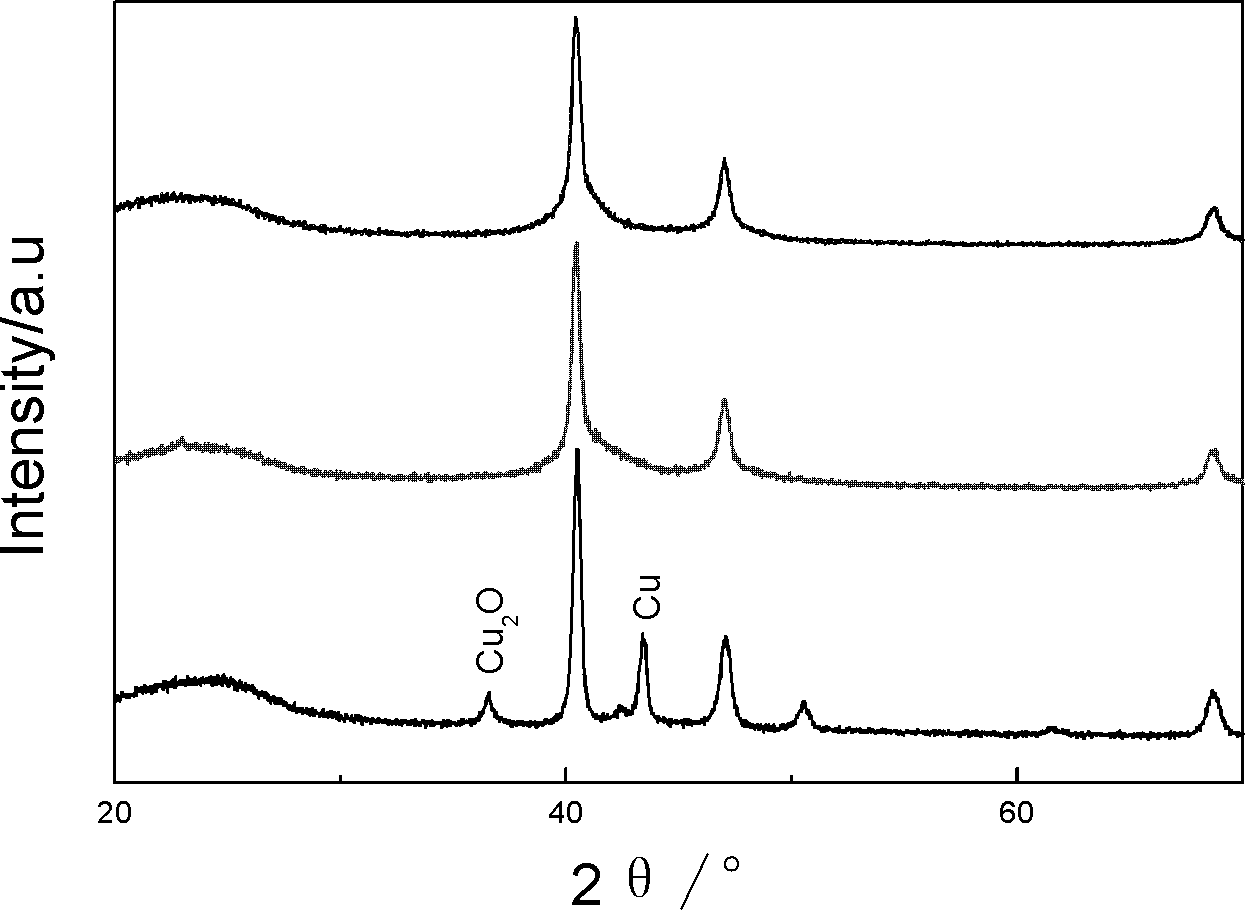

[0027] (1) Weigh 39.32mg copper sulfate pentahydrate (10mg Cu), 50mg citric acid (C 6 h 8 o 7 ), 30ml ethylene glycol was put into the there-necked flask, and then 1.666ml palladium chloride aqueous solution (10mg Pd, 10g / L PdCl 2 Aqueous solution), wherein copper sulfate pentahydrate and palladium chloride are the precursors of Cu and Pd simple substances, citric acid is used as complexing agent to prevent agglomeration to generate larger nanoparticles, ethylene glycol is used as solvent and reducing agent, and its larger The viscosity can also help to generate small and uniform catalyst particles. After the copper sulfate pentahydrate is dissolved, add 80 mg of Vulcan XC-72 conductive carbon black (XC-72 carbon spheres) to the solution, stir well to disperse the carbon powder evenly, and obtain a mixed solution.

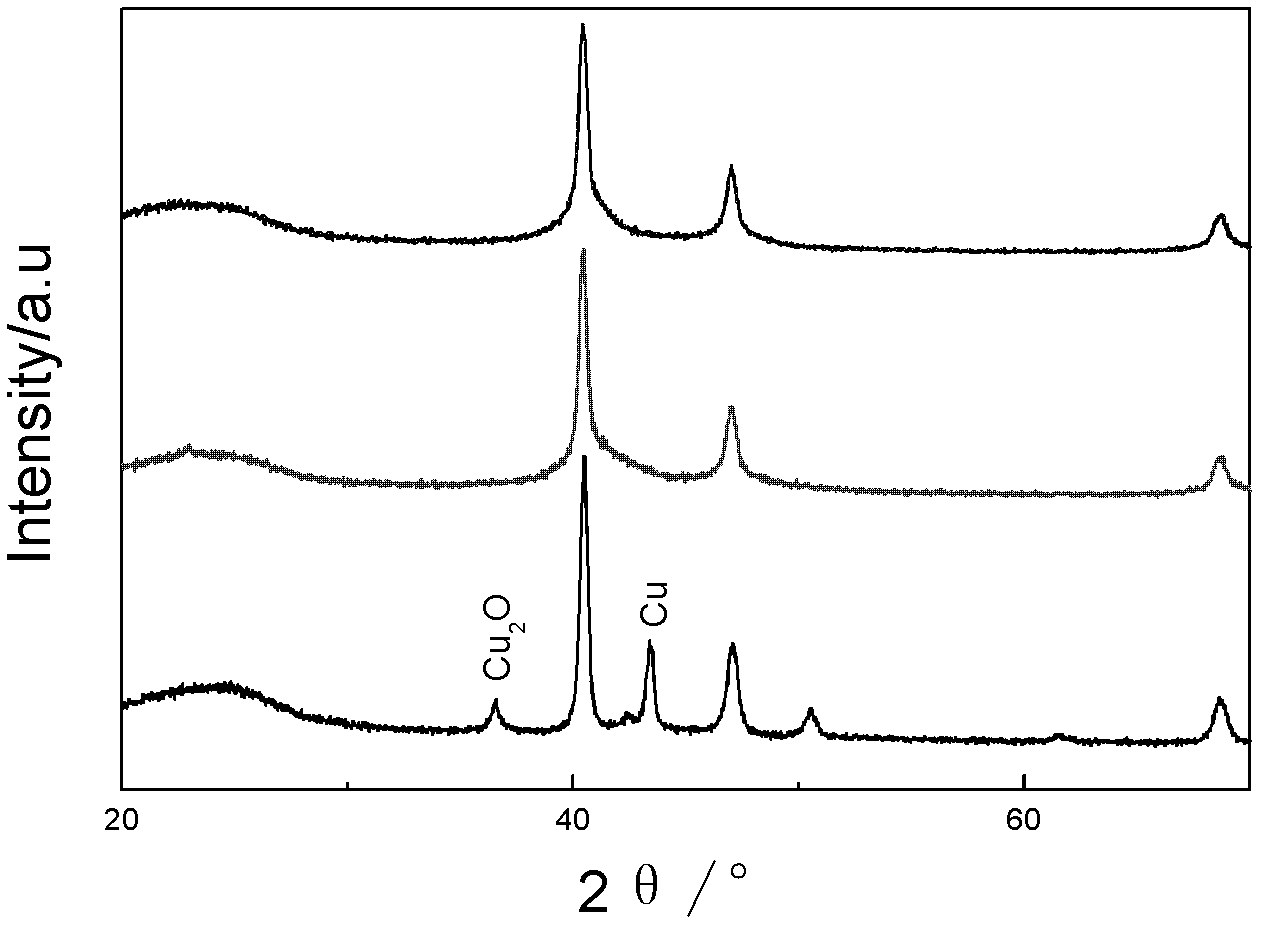

[0028] (2) Then adjust the pH of the mixed solution to 10 with potassium hydroxide in ethylene glycol (KOH / EG) solution. The temperature of the mixture was rai...

Embodiment 2

[0035] (1) Weigh 19.66mg copper sulfate pentahydrate (5mg Cu), 50mg citric acid (C 6 h 8 o 7 ), 30ml ethylene glycol was put into the there-necked flask, and then 833ul palladium chloride aqueous solution (5mg Pd, 10g / L PdCl 2 aqueous solution). Wherein copper sulfate pentahydrate and palladium chloride are the precursors of Cu and Pd simple substance, citric acid is used as complexing agent to prevent agglomeration from generating larger nanoparticles, ethylene glycol is used as solvent and reducing agent, and its larger viscosity also Can help to generate small and uniform catalyst particles. After the copper sulfate pentahydrate is dissolved, add 80 mg of Vulcan XC-72 conductive carbon black (XC-72 carbon spheres) to the solution, stir well to disperse the carbon powder evenly, and obtain a mixed solution.

[0036] (2) Then adjust the pH of the mixture to 10 with KOH / EG. The temperature of the mixture was raised to 170°C, and the reaction time was 4 hours. During the t...

Embodiment 3

[0040] (1) Weigh 19.66mg copper sulfate pentahydrate (5mg Cu), 50mg citric acid (C 6 h 8 o 7 ) 30ml ethylene glycol is put into the there-necked flask, then add 470ul palladium chloride aqueous solution (5mg Pd, 17g / L PdCl 2 aqueous solution). Wherein copper sulfate pentahydrate and palladium chloride are the precursors of Cu and Pd simple substance, citric acid is used as complexing agent to prevent agglomeration from generating larger nanoparticles, ethylene glycol is used as solvent and reducing agent, and its larger viscosity also Can help to generate small and uniform catalyst particles. After the copper sulfate pentahydrate is dissolved, add 80 mg of Vulcan XC-72 conductive carbon black (XC-72 carbon spheres) to the solution, stir well to disperse the carbon powder evenly, and obtain a mixed solution.

[0041] (2) Then adjust the pH of the mixture to 10 with KOH / EG. The temperature of the mixture was raised to 190°C, and the reaction time was 2 hours. During the tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com