Method for automatic identifying steel slab coding and steel slab tracking system

An automatic identification and slab technology, applied in closed-circuit television systems, character and pattern recognition, television systems adapted to optical transmission, etc. Consistent information, no problems such as automatic tracking of steel slabs, etc., to achieve the effect of simple human-computer interface design, improved logistics management level, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

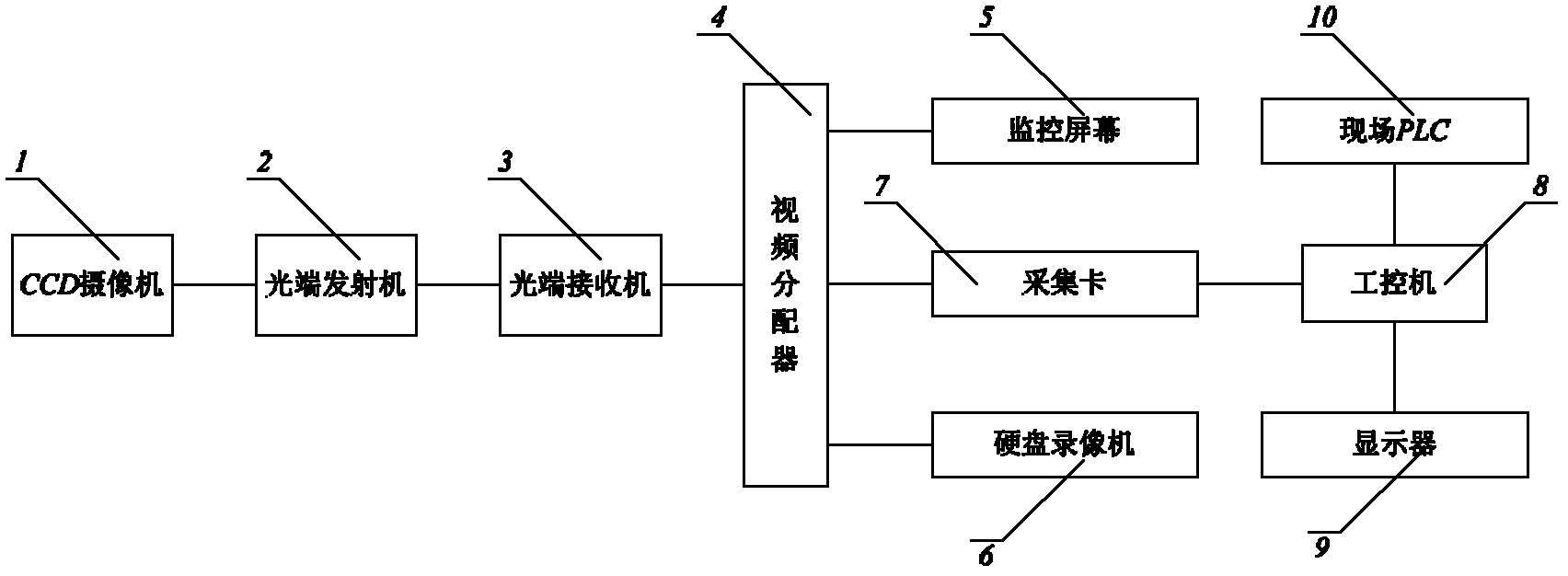

[0097] The slab automatic identification and tracking system based on the steel slab coded image in the present embodiment consists of a CCD camera 1, an optical transmitter 2, an optical receiver 3, a video distributor 4, a monitoring screen 5, a hard disk video recorder 6, and a collection card 7, industrial computer 8, display 9, and on-site PLC 10, such as figure 1 As shown, CCD camera 1 is responsible for shooting slab video. The optical transceiver is a device that converts optical signals and electrical signals. The optical transmitter 2 receives electrical signals and converts them into optical signals; the optical receiver 3 receives optical signals and converts them into electrical signals; the function is to convert video information into Optical information realizes video transmission through optical fiber, and optical fiber transmission has the advantages of low loss, anti-interference and large capacity, thereby reducing the loss of video signals, enhancing anti-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com