Performance sampling verification method for propeller current meter

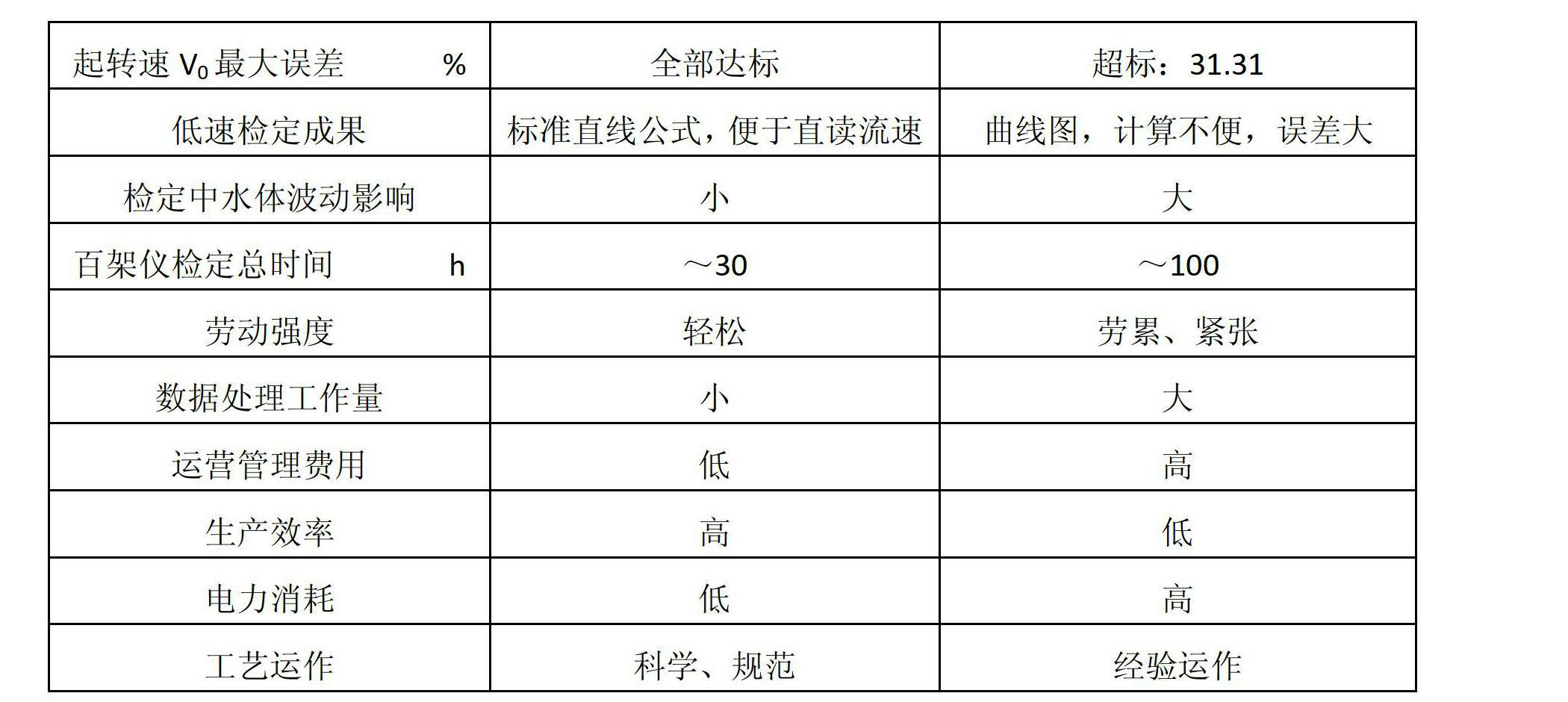

A current meter and propeller technology, which is applied in the field of sampling verification of the performance of the propeller current meter in river hydrological testing, can solve the problems of lack of technical index monitoring means, high labor intensity, and car collision accidents, and achieve scientific process operation, low labor intensity, The effect of high test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The following is an explanation of the theory of this case, a block-by-block description of the preferred scheme of this case, and a verification result combined with specific examples.

[0069] Related Explanation of Theory

[0070] 1. Hydraulic pitch K of the propeller current meter

[0071] Assuming that the instrument has no internal friction resistance, the main parameters of the motion equation of the propeller current meter are deduced by the theory of fluid mechanics:

[0072] K={[C Y / (C X -C Y )tan 2 α]+[C X / (C Y -C X )]}πDtanα (2)

[0073] In the formula: C X is the propeller surface resistance coefficient; C Y is the resistance coefficient of the propeller airfoil structure; tanα is the propeller tangent of the measured cross-section of the propeller; the big scratch is the propeller drag coefficient, represented by B; πDtanα is the geometric pitch of the propeller, represented by H; so the above formula is simplified as:

[0074] K=BH (3)

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com