A wireless acceleration sensor for vibration monitoring

An acceleration sensor and vibration monitoring technology, applied in the field of sensors, can solve the problems of installing expensive communication lines and widely used in the industry of wired automation systems, and achieve the effects of light structure, convenient assembly and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] This type of wireless acceleration sensor is developed to meet the vibration monitoring needs of industrial machines, pumps and equipment in related industries. Compared with indoor environmental monitoring, civil engineering monitoring, and agricultural monitoring, the vibration monitoring of industrial machines and pumps has the characteristics of larger data volume, higher data real-time and accuracy requirements, and greater power consumption. Constrained by the installation conditions of industrial sites and various dangerous working conditions, wireless sensors can only be powered by batteries with limited energy, which limits the power consumption level and computing power of sensors, and brings great challenges to the design. The present invention will solve the above-mentioned problems from the following several specific implementation modes.

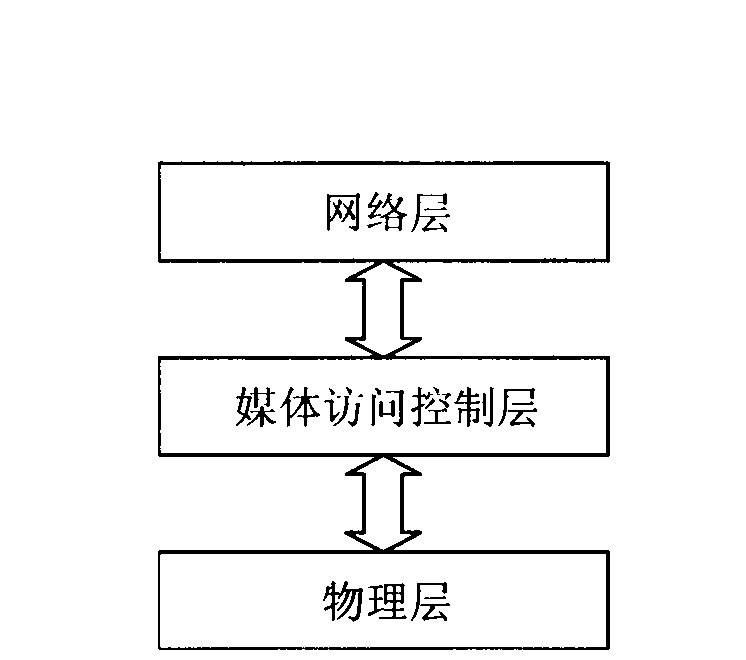

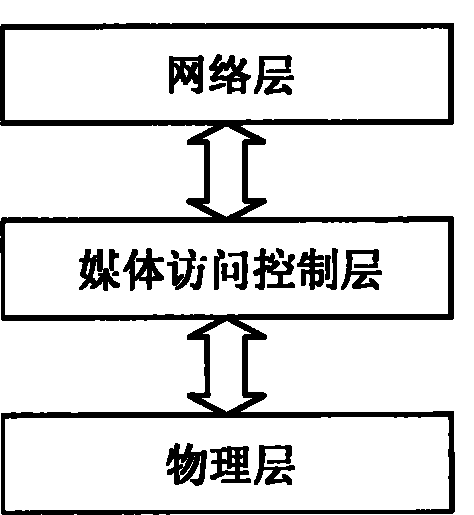

[0024]The first is the design of the wireless acceleration sensor software system. The software system adopting hiera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com