Microbial preparation for shortening tobacco fermentation period and application of microbial preparation

A microbial preparation and fermentation cycle technology, applied in the directions of microorganisms, microorganisms, and microorganism-based methods, can solve problems such as the gap in the quality improvement effect of tobacco leaves and the lack of artificial fermentation agents, and achieve reduced irritation, improved taste, and green and miscellaneous air reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Mix the bacteria slime of Bacillus cereus and Bacillus amyloliquefaciens according to the ratio of the number of viable bacteria 4:1, add 1.2% trehalose, 1.8% glycerin, and 1.0% sodium glutamate by weight percentage as the composite freeze-dried mixture of the bacteria sludge The protective agent is freeze-dried to obtain a powdered microbial preparation.

[0027]Dissolve the powdered microbial preparation in sterile water at a ratio of 1%, and after fully stirring, take 10Kg of the microbial preparation and evenly spray it on 100kg of tobacco leaves, and artificially ferment it at 45°C and 80%RH for 22 days to achieve the invention. The effect described in the content.

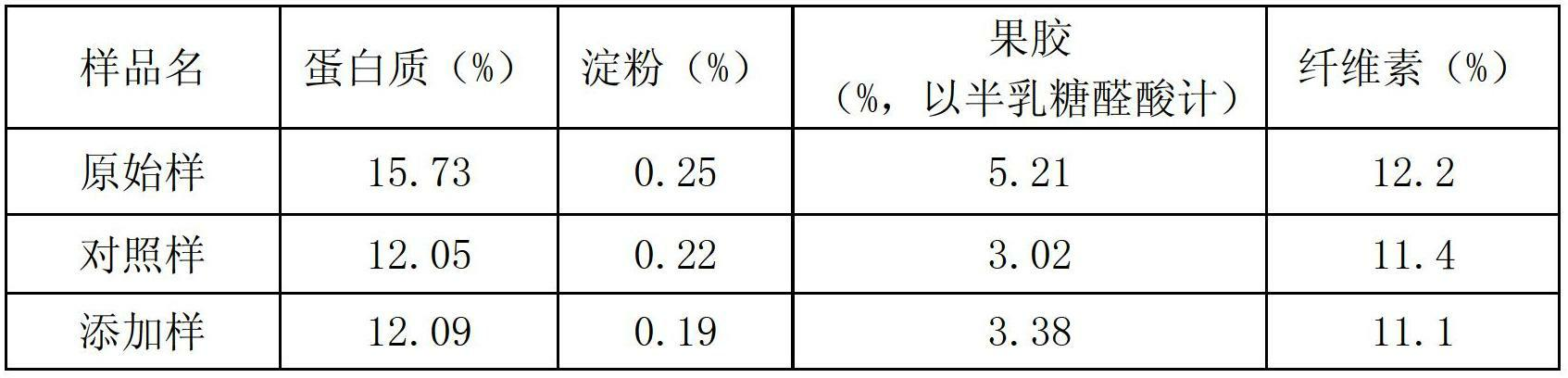

[0028] Compared with the unfermented tobacco leaves (original sample), the protein content of the tobacco leaves (added sample) after adding the microbial preparation of the present invention and artificially fermented for 22 days is significantly lower; The taste was improved, and the quality was equ...

Embodiment 2

[0034] Mix the bacteria slime of Bacillus cereus and Bacillus amyloliquefaciens according to the ratio of viable bacteria 10:1, add 2% trehalose, 2% glycerin, and 1.5% sodium glutamate by weight percentage as the composite freeze-dried mixture of the bacteria sludge The protective agent is freeze-dried to obtain a powdered microbial preparation.

[0035] Dissolve the powdered microbial preparation in sterile water at a ratio of 5%, and after fully stirring, take 8Kg of the microbial preparation and evenly spray it on 100kg of tobacco leaves, and artificially ferment it for 30 days at 35°C and 70%RH to achieve the invention. The effect described in the content.

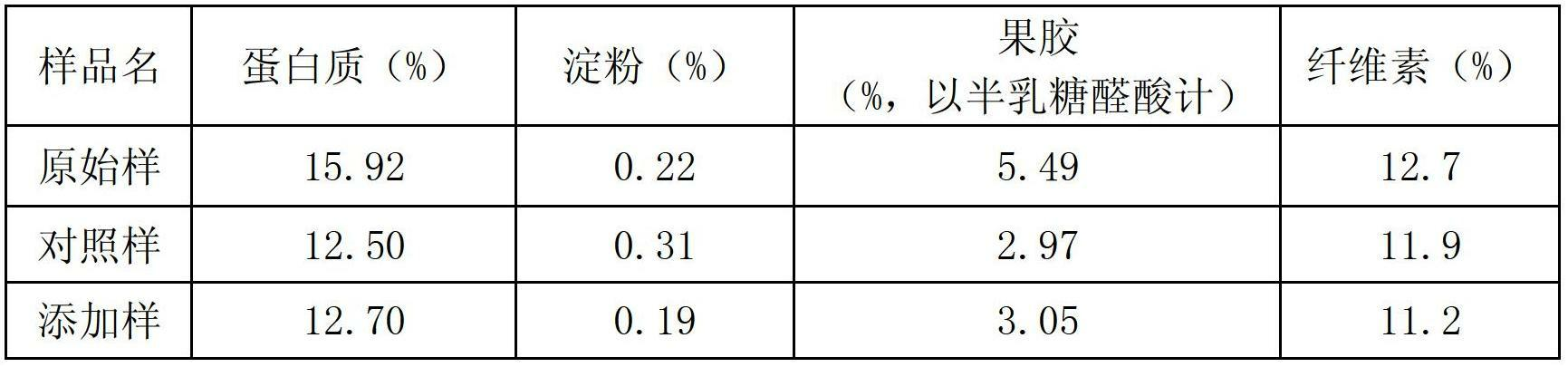

[0036] Compared with the unfermented tobacco leaves (original sample), the protein content of the tobacco leaves (added sample) after adding the microbial preparation of the present invention and artificially fermented for 30 days is significantly lower; The taste was improved, and the quality was comparable to that o...

Embodiment 3

[0042] Mix the bacteria slime of Bacillus cereus and Bacillus amyloliquefaciens according to the ratio of the number of viable bacteria 1:5, add 1% trehalose, 2.8% glycerin, and 1% sodium glutamate by weight percentage as the composite freeze-dried mixture of the bacteria sludge The protective agent is freeze-dried to obtain a powdered microbial preparation.

[0043] According to the proportion of 3%, the microbial preparation was dissolved in sterile water, after fully stirring, 5Kg of the bacterial preparation was evenly sprayed and added to 100kg of tobacco leaves, and artificially fermented for 52 days at 25°C and 70%RH conditions, which can reach the content of the invention. the effect described.

[0044] Compared with the unfermented tobacco leaves (original sample), the protein content of the tobacco leaves (added sample) after adding the microbial preparation of the present invention and artificially fermented for 52 days was significantly lower; The taste was improv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com