Circuit board cleaning agent replacing trichloroethylene

A technology of circuit board cleaning agent and trichlorethylene, which is applied in the field of cleaning agent, can solve the problems of corrosion of electronic components, large damage to human body, bad electronic products, etc., and achieve the effect of meeting the cleaning requirements, strong dissolving ability and low toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

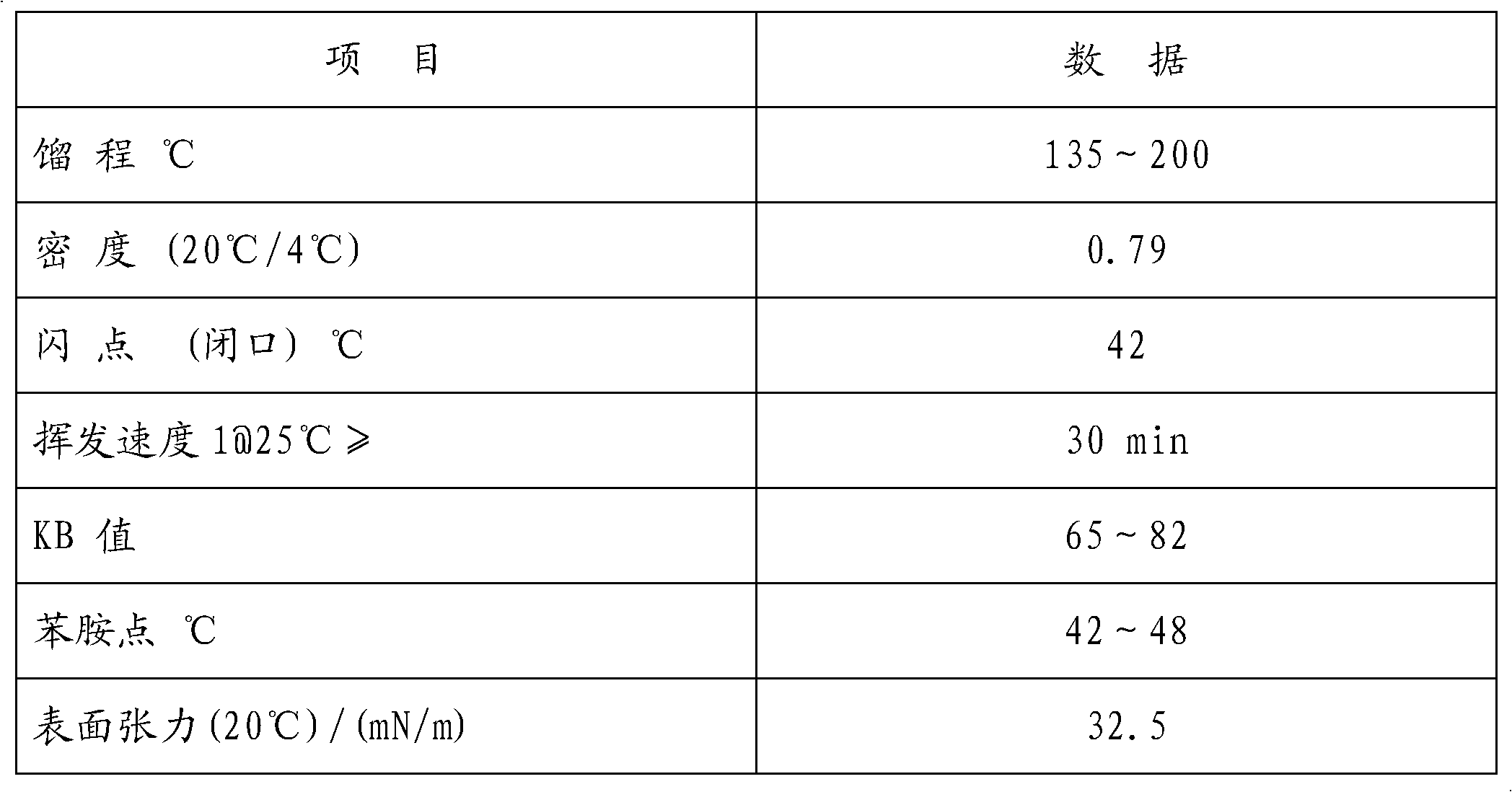

Image

Examples

Embodiment 1

[0016] A kind of circuit board cleaning agent that replaces trichlorethylene, is made up of each component of following mass percentage:

[0017] Naphthenes 38%;

[0018] Ether additives 23%;

[0019] Ketone additives 18%;

[0020] Ester additives 11%.

[0021] Multifunctional additive 10%

[0022] The cycloalkane is cyclopentane, the ether additive is ethylene glycol methyl ether, the ketone additive is methyl isobutyl ketone, and the ester additive is ethyl formate.

Embodiment 2

[0024] A kind of circuit board cleaning agent that replaces trichlorethylene, is made up of each component of following mass percentage:

[0025] Naphthenes 22%;

[0026] Ether additives 27%;

[0027] Ketone additives 15%;

[0028] Ester additives 26%.

[0029] Multifunctional additive 10%

[0030] Cycloheptane is selected as the cycloalkane, propylene glycol butyl ether is selected as the ether additive, butanone is selected as the ketone additive, and ethyl acetate is selected as the ester additive.

Embodiment 3

[0032] A kind of circuit board cleaning agent that replaces trichlorethylene, is made up of each component of following mass percentage:

[0033] Naphthenes 23%;

[0034] Ether additives 26%;

[0035] Ketone additives 12%;

[0036] Ester additives 29%.

[0037] Multifunctional additive 10%

[0038] The cycloalkane is cyclooctane, the ether additive is diethylene glycol ether, the ketone additive is phorone, and the ester additive is butyl acetate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com