Preparation method of environment-friendly rubber tire filling oil

A technology for rubber tires and a production method, which is applied in the field of production methods for environmentally friendly rubber tire filling oil, can solve the problems of low utilization rate of raw materials, narrow application fields, etc., and achieves high utilization rate of raw materials, easy realization of conditions, and simple production process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

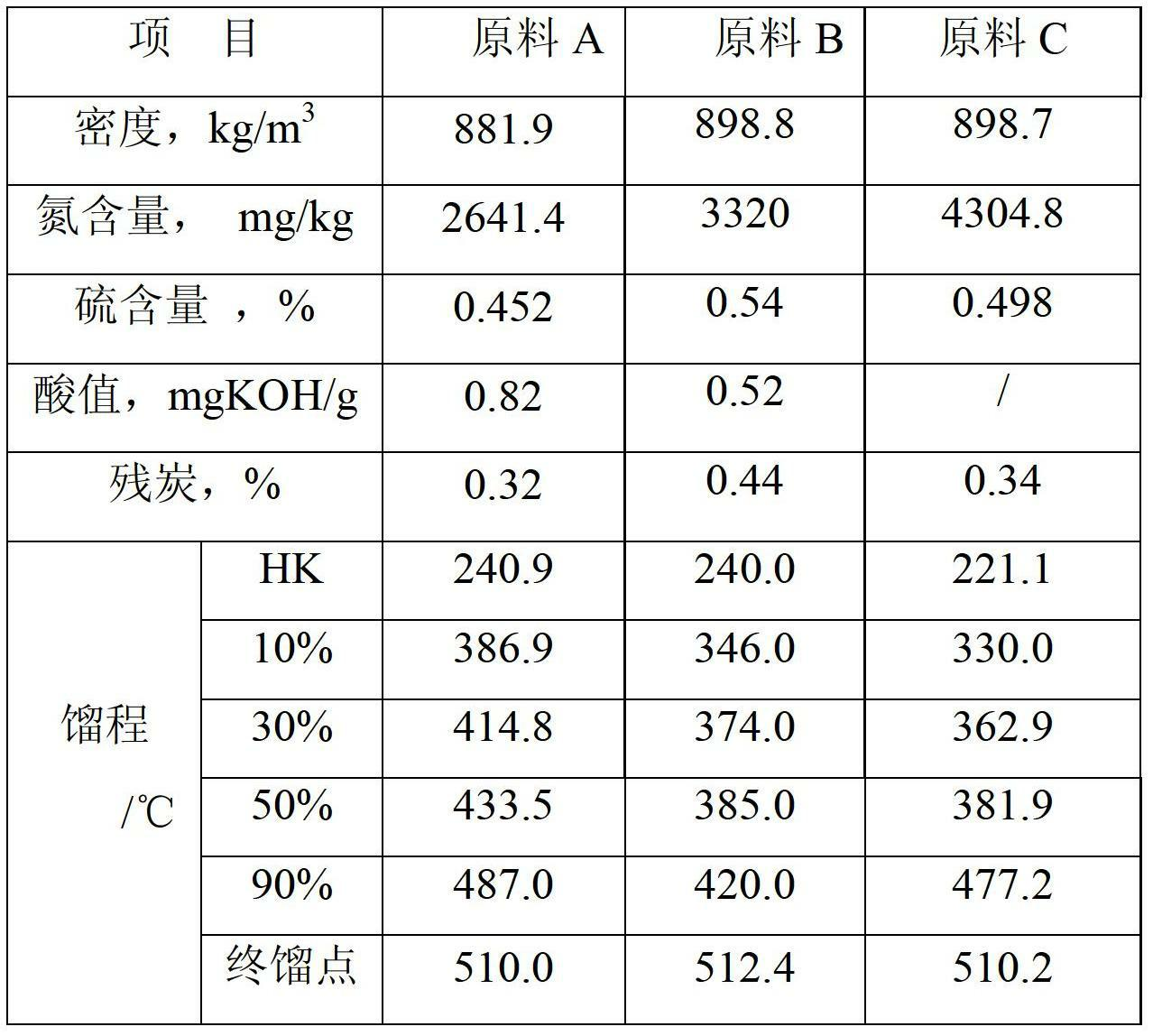

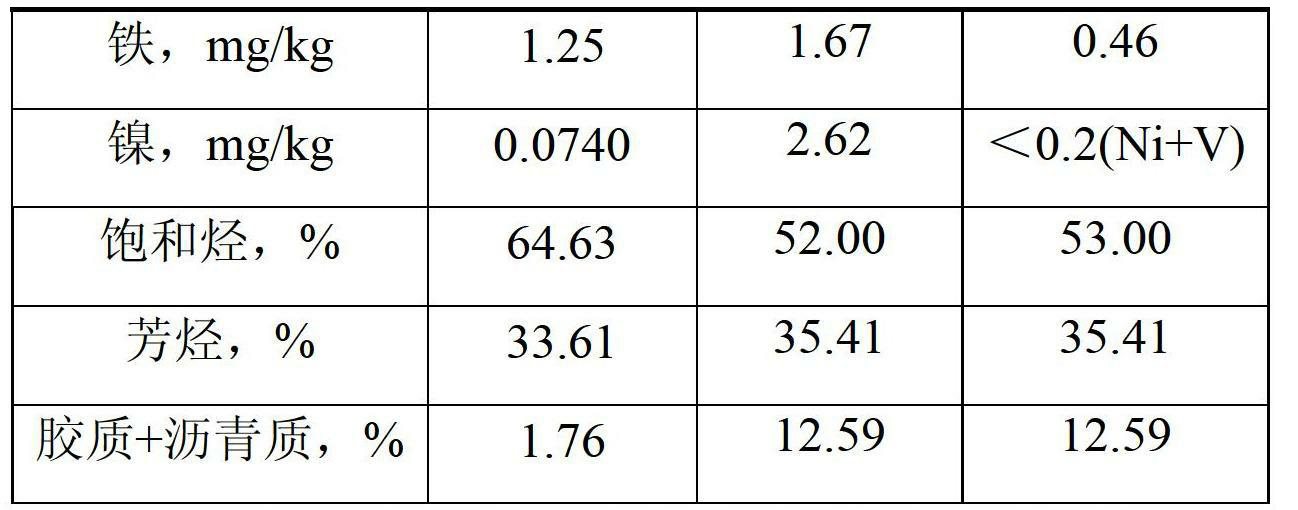

[0022] The properties of the raw material oil of coker wax oil with a distillation range of 230-570°C are as shown in Table 1. Distillation under reduced pressure, and the fraction at 350-520°C is collected.

[0023] The hydrogenation test experiment was carried out on a 100ml fixed bed hydrogenation reaction test device. The constant temperature section in the reactor was loaded with hydrogenation pre-refining, hydrogenation upgrading, hydrogenation post-refining three-stage one-stage hydrogenation catalyst, and the three-stage catalyst was loaded The volume ratio is 2:1:3. The collected distillate is pre-mixed with hydrogen and enters from the upper part of the hydrogenation reactor to react with the catalyst. Hydrogenation was carried out in a single-pass manner in the test. Remove undesired components in raw materials. Control the reaction conditions so that the hydrogen partial pressure is 18MPa, the reaction temperature is 350°C, and the liquid space velocity is 0.9h ...

Embodiment 2

[0026] Using the process mode of Example 1, the properties of the coking wax oil raw material oil are as shown in Table 1. The process conditions of the coking wax oil of raw material A are: hydrogen partial pressure of 16.5 MPa, reaction temperature of 365 ° C, and liquid space velocity of 0.7 h -1 , the volume ratio of hydrogen to oil is 500, and the catalyst for hydrogenation pre-refining is: calculated on a dry basis of oxides, WO 3 It accounts for 25% of the total weight of the catalyst, NiO accounts for 6% of the total weight of the catalyst, and the balance is a titanium-containing modified silicon-aluminophosphate carrier; the composition of the catalyst for hydrogenation modification is: based on the dry basis of oxides, NiO accounts for the total weight of the catalyst 4% of the total weight of the catalyst, beta zeolite accounts for 10% of the total weight of the catalyst, ZSM-5 accounts for 50% of the total weight of the catalyst, and the balance is alumina powder. ...

Embodiment 3

[0029] Using the process mode of Example 1, the properties of the coking wax oil raw material oil are as shown in Table 1. The process conditions of the coking wax oil of raw material B are: hydrogen partial pressure is 17.5MPa, reaction temperature is 380°C, and liquid space velocity is 1.0h -1 , the volume ratio of hydrogen to oil is 630, and the catalyst for hydrogenation pre-refining is: based on the dry basis of oxides, WO 3 It accounts for 30% of the total weight of the catalyst, NiO accounts for 4% of the total weight of the catalyst, and the balance is a titanium-containing modified silicon-aluminophosphate carrier; the composition of the catalyst for hydrogenation modification is: based on the dry basis of oxides, NiO accounts for the total weight of the catalyst 5%, beta zeolite accounts for 8% of the total weight of the catalyst, ZSM-5 accounts for 60% of the total weight of the catalyst, and the balance is alumina powder. The refined catalyst after hydrogenation is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com