A kind of preparation method based on water-based one-component polyurethane wood lacquer

A polyurethane and wood paint technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems affecting the opening effect and chemical properties of products, and achieve the effects of improving physical properties, improving opening effects, and increasing chemical resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

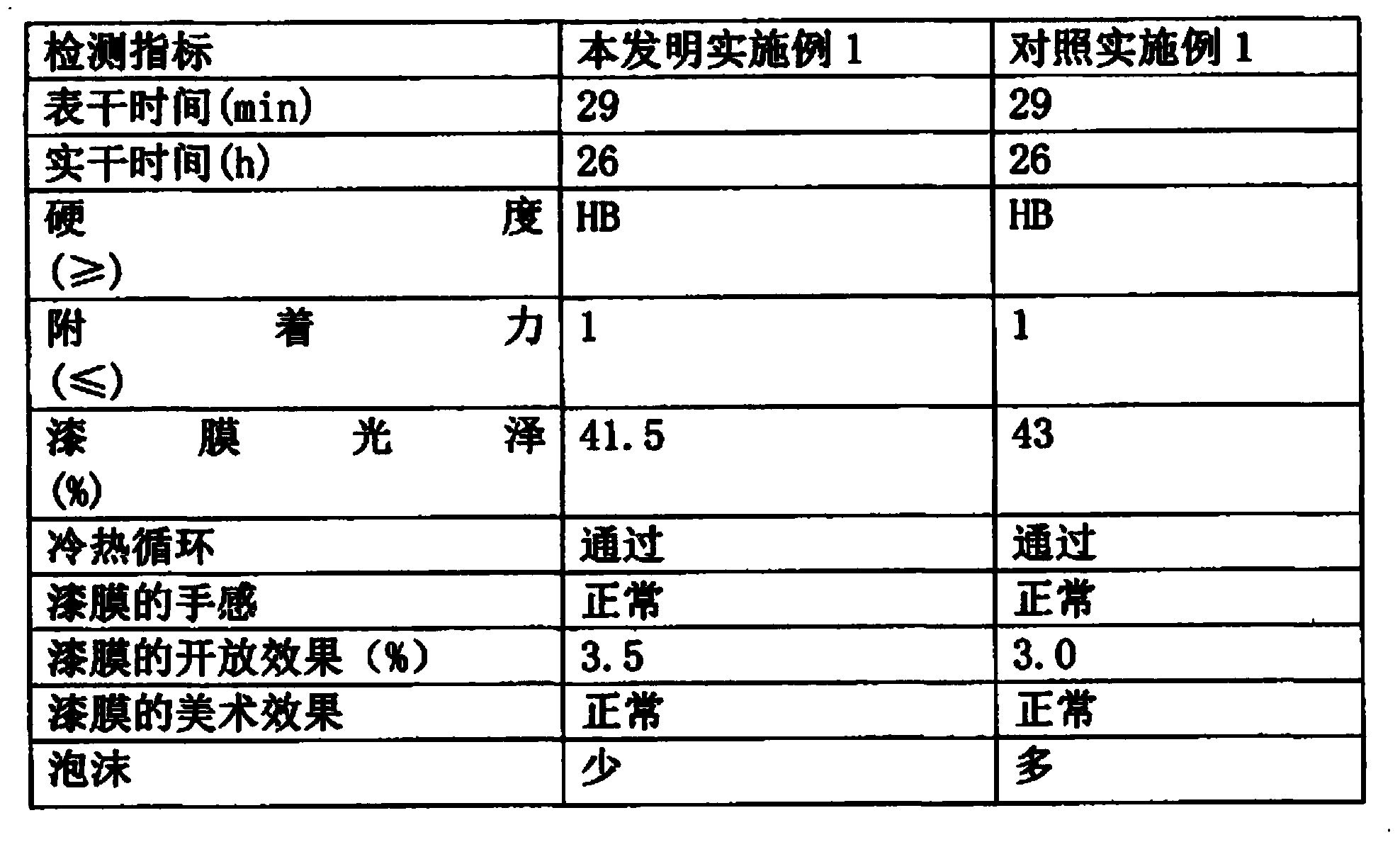

Examples

Embodiment 1

[0024] The water-based one-component polyurethane wood lacquer of the embodiment of the present invention is composed of the following components by weight: 81% of water-based one-component polyurethane, 1% of epoxy siloxane, 1.5% of water-soluble silicone, and 16.5% of water.

[0025] The preparation method of the water-based one-component polyurethane wood varnish based on the embodiment of the present invention is:

[0026] (1) Prepare raw materials: water-based one-component polyurethane dispersion, epoxy siloxane, water-based silicone, water;

[0027] (2) Under normal temperature conditions, firstly put into water-based one-component polyurethane dispersion;

[0028] (3) under the rotating speed of 350-650 per minute, put into epoxy siloxane and water-based organosilicon sequentially in proportion;

[0029] (4) Then, at a rotating speed of 700-1400 per minute, disperse at a high speed for 15 minutes, control the temperature below 50 °C, and control the fineness to be les...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com