Method for preparing ethyl levulinate by using straw-type biomass

A technology of ethyl levulinate and biomass, which is applied in the directions of lignin derivatives, chemical instruments and methods, reaction preparation of ester groups and hydroxyl groups, etc., can solve the problems of many by-products, low product concentration, and high production costs, and achieves The reaction time is short, the product concentration is high, and the utilization rate is improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

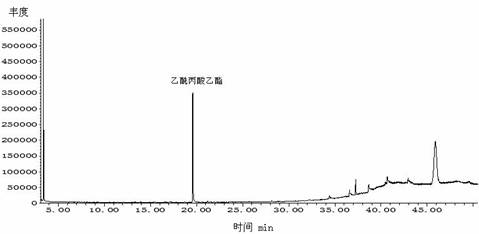

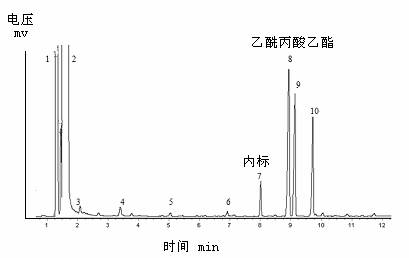

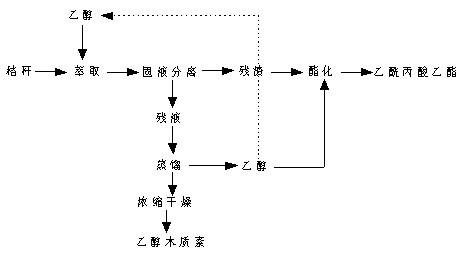

[0021] (1) In the autoclave, add 7g of wheat straw (containing 39.46% cellulose) and 70ml of 85% ethanol, maintain the pressure at 1.0Mpa, and the reaction time is 3h. After the reaction, perform vacuum filtration for solid-liquid separation to obtain the filtrate and 5g of filter residue; (2) After the filtrate is distilled, ethanol is recovered, and the recovered ethanol can be recycled for the pretreatment of straw and the next reaction, and the filtrate after recovery of ethanol is concentrated and dried to obtain ethanol lignin; (3) The filter residue is In the still, add 50ml of sulfuric acid ethanol solution, the volume concentration of sulfuric acid in the sulfuric acid ethanol solution is 5%, and react at 170°C for 60min to obtain a hydrolyzate containing ethyl levulinate. The GC-MS spectrum and GC spectrum of the hydrolyzate are as follows: figure 1 , 2 Shown, utilize GC-MS qualitative hydrolyzate main product to be ethyl levulinate (19.58min), chromatographic quant...

Embodiment 2

[0023] (1) In the autoclave, add 7.5g of corn stalks (containing 35.20% cellulose) and 150ml of 90% ethanol, maintain the pressure at 1.5Mpa, and the reaction time is 2.5h. After the reaction, perform solid-liquid separation by pressure filtration to obtain Filtrate and 5.6g filter residue; (2) After the filtrate is distilled, ethanol is recovered, and the recovered ethanol can be recycled for the pretreatment of straw and the next reaction, and the filtrate after recovering ethanol is concentrated and dried to obtain ethanol lignin; (3) Filter residue In the autoclave, add 84ml ethanol solution of hydrochloric acid, the volume concentration of hydrochloric acid in the ethanol solution of hydrochloric acid is 2.5%, and react at 190°C for 30min to obtain a hydrolyzate containing ethyl levulinate. Utilize GC-MS qualitative hydrolyzate main product to be ethyl levulinate, chromatographic quantitative analysis shows that the quality of ethyl levulinate is 1.23g, and the productive ...

Embodiment 3

[0025] (1) In the autoclave, add 6g of sorghum straw (containing 32.50% cellulose) and 180ml of 95% ethanol, maintain the pressure at 2.0 Mpa, and the reaction time is 1.0 h. After the reaction is completed, perform solid-liquid separation by pressure filtration to obtain the filtrate and 5.85g of filter residue; (2) After the filtrate is distilled, ethanol is recovered, and the recovered ethanol can be recycled for the pretreatment of straw and the next reaction, and the filtrate after recovery of ethanol is concentrated and dried to obtain ethanol lignin; (3) The filter residue is in In the autoclave, add 117ml of phosphoric acid ethanol solution, the volume concentration of phosphoric acid in the phosphoric acid ethanol solution is 1.0%, and react at 220°C for 10 minutes to obtain a hydrolyzate containing ethyl levulinate. Utilize GC-MS qualitative hydrolyzate main product to be ethyl levulinate, chromatographic quantitative analysis, the quality of ethyl levulinate 0.9g, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com