Method of treating wastewater containing organic compound

A treatment method and waste liquid technology, applied in the direction of biological water/sewage treatment, special treatment targets, chemical instruments and methods, etc., can solve problems such as inability to fully eliminate scum, achieve low cost, eliminate warm waste changes, and stabilize treatment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0125] Activated sludge is used to treat the degreasing agent-containing waste liquid discharged from electroplating factories and printing factories as follows.

[0126] The degreaser-containing waste liquid contains at least dipropylene glycol ether, alkylbenzimidazole, benzimidazole derivatives, diethylene glycol monobutyl ether, monoethanolamine, polyoctylphenyl ether, isopropanol, ethylene glycol , N, N'-dimethylformamide, etc.

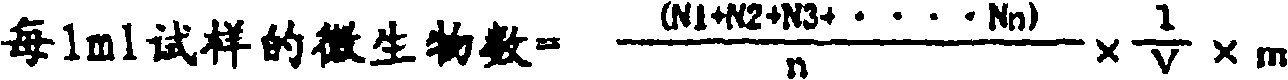

[0127] For the degreasing agent-containing waste liquid, its biochemical oxygen demand (BOD), chemical oxygen demand (COD), total nitrogen and total phosphorus were measured respectively. The BOD uses a trade name: DO Meter-OM 12 (manufactured by Horiba Manufacturing Co., Ltd.), and the amount of dissolved oxygen in the sample after culturing for 5 days and the amount of dissolved oxygen in the sample before culturing are measured by conventional methods. Numerical calculation of dissolved oxygen before and after cultivation. This COD is evalua...

Embodiment 2

[0157] The isolated IBI-2P, IBI-3P, IBI-6P, IBI-15P, IBI-40P and IBI-6 were cultured separately. Next, in the above-mentioned Example 1, the obtained IBI-2P, IBI-3P, IBI-6P, IBI-15P, IBI-40P and IBI-6 were used instead of the activated sludge. liquid is processed.

[0158] As a result, one week later, treated water meeting the water discharge standards (BOD: 130 ppm, COD: 245 ppm, total nitrogen: 75 ppm, and total phosphorus: 15 ppm) was obtained at a residence time of 42 hours. The abundance ratio (cell number ratio) of the above-mentioned IBI-2, IBI-3P, IBI-6P, IBI-15P, IBI-40P and IBI-6 is about 1:1:1:1:1:1. According to the waste liquid containing degreasing agent, take IBI-6 as 100, IBI-2P is about 20-50, and the above-mentioned IBI-3P, IBI-6P, IBI-15P and IBI-40P show the degree of stability within the fluctuation of about 1-10 .

Embodiment 3

[0163] Activated sludge is used to treat waste liquid containing degreasing agents discharged from electroplating factories and printing factories as follows.

[0164] The above-mentioned degreasing agent-containing waste liquid contains at least dipropylene glycol ether, alkylbenzimidazole, benzimidazole derivatives, diethylene glycol monobutyl ether, monoethanolamine, polyoctylphenyl ether, isopropanol, ethylene glycol , N, N'-dimethylformamide, ethylene glycol, etc.

[0165] Biochemical oxygen demand (BOD), chemical oxygen demand (COD), total nitrogen and total phosphorus were measured for the waste liquid containing degreasing agent. The above-mentioned BOD is calculated as follows according to a conventional method: using a trade name: DO Meter-OM 12 (manufactured by Horiba Manufacturing Co., Ltd.), the amount of dissolved oxygen in the sample after culturing for 5 days and the amount of dissolved oxygen in the sample before culturing The measurement was performed, and c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com