Energy-saving evaporation process and system thereof

A process system and process technology, applied in evaporation, general water supply saving, heating water/sewage treatment, etc., can solve the problems of high investment cost and maintenance cost, complex structure of steam compressor, low carrying ratio, etc., and achieve simple operation and maintenance. Easy to operate, the system is simple and easy to operate, and the effect is fully utilized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

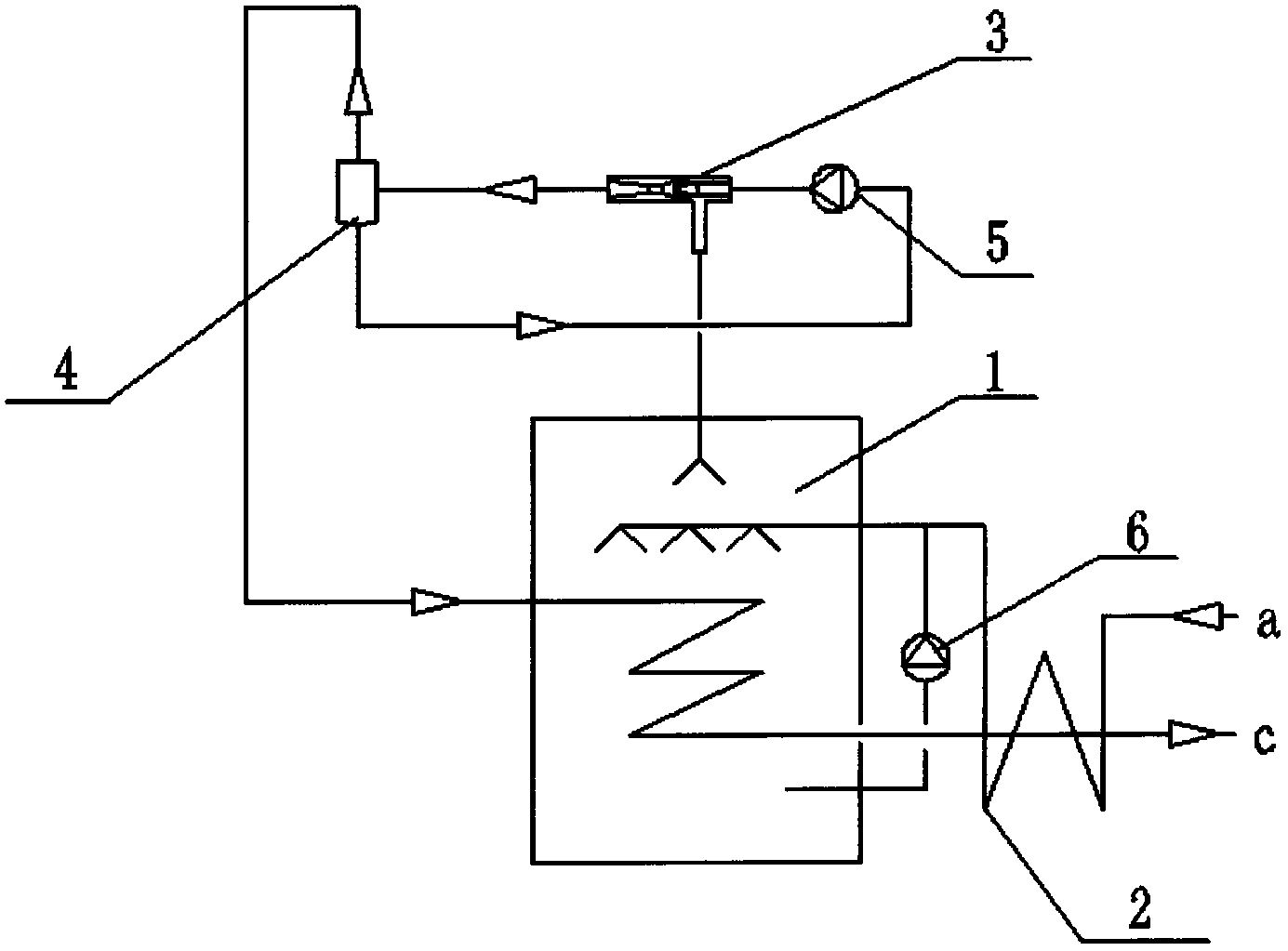

[0013] Refer to attached figure 1 : The process system is composed of evaporator 1, heat exchanger 2, water injector 3, vapor-liquid separator 4, high-pressure water pump 5, circulating water pump 6, raw material liquid a and condensate liquid c. Among them, the raw material liquid a is connected to the feed liquid inlet of the heat exchanger 2 through the conveying pipeline, the feed liquid outlet of the heat exchanger 2 is connected to the feed liquid inlet of the evaporator 1 through the conveying pipeline, and the concentrated liquid of the raw material liquid a is passed through the circulating water pump 6 at the same time It is connected to the feed liquid inlet of evaporator 1, and the secondary steam output from evaporator 1 is connected to the high-temperature and high-pressure water injection circulation system through the water ejector. The water injection circulation system includes high-pressure water pump 5, water ejector 3 and vapor-liquid separator 4. The cond...

Embodiment 2

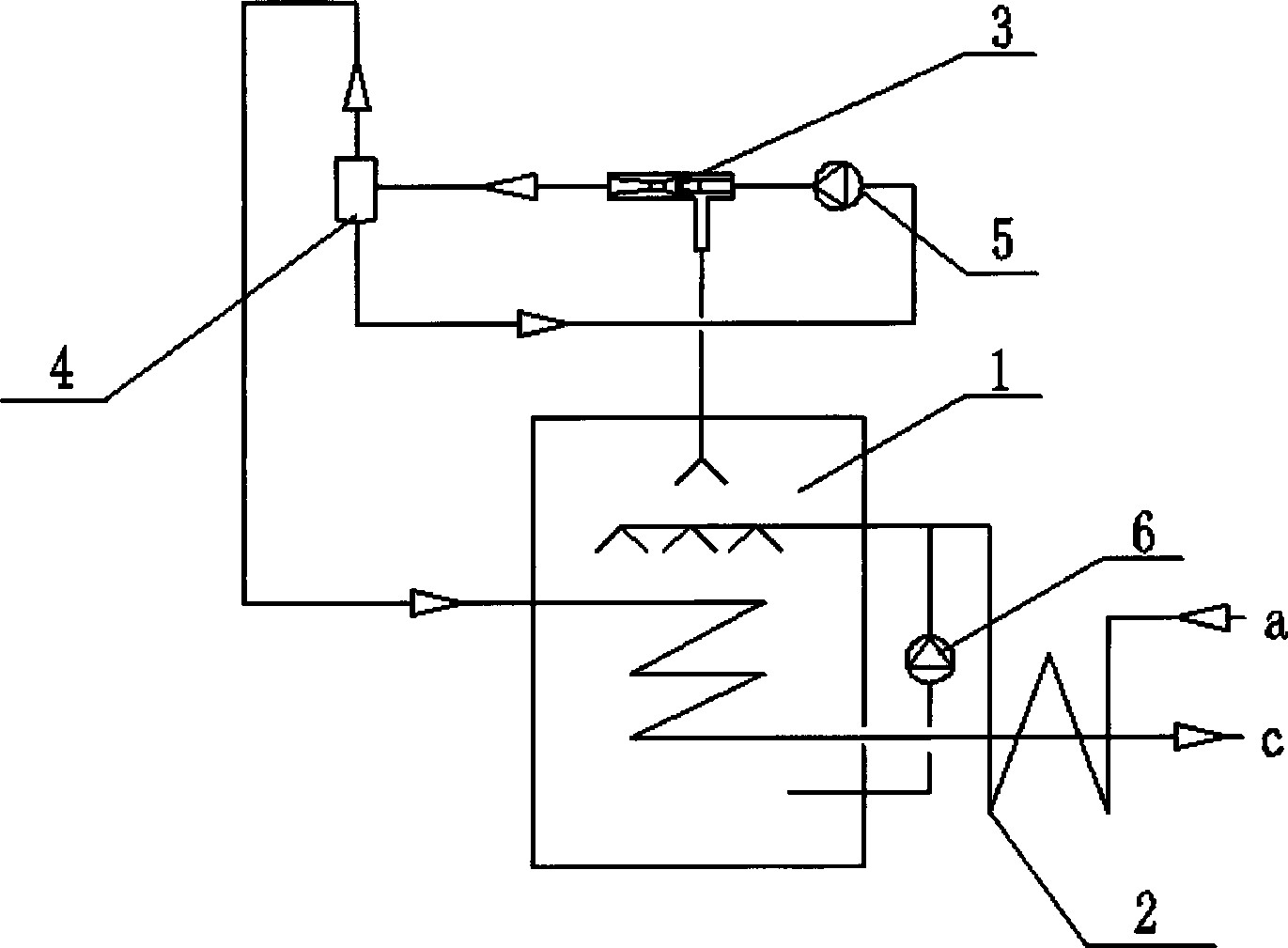

[0016] Refer to attached figure 2 : According to the actual situation, part of raw steam b can be supplemented when the system is running. The process system consists of evaporator 1, heat exchanger 2, water injector 3, vapor-liquid separator 4, high-pressure water pump 5, circulating water pump 6, raw material a , raw steam b and condensate c. Among them, the raw material liquid a is connected to the feed liquid inlet of the heat exchanger 2 through the conveying pipeline, the feed liquid outlet of the heat exchanger 2 is connected to the feed liquid inlet of the evaporator 1 through the conveying pipeline, and the concentrated liquid of the raw material liquid a is passed through the circulating water pump 6 at the same time It is connected with the feed liquid inlet of the evaporator 1, and the secondary steam output from the evaporator 1 is connected with the high-temperature and high-pressure liquid injection cycle system through the water injector. The liquid in the liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com