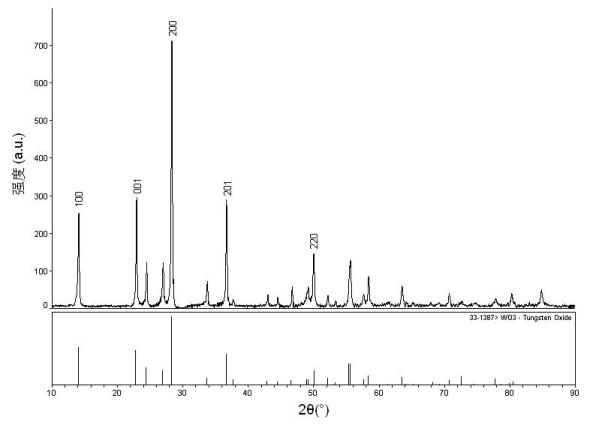

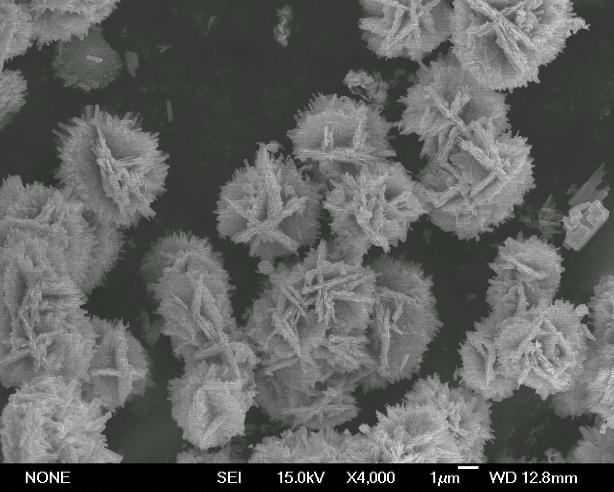

Preparation method of WO3 nanosphere

A new technology of nanospheres, applied in the field of preparation of new WO3 nanospheres, can solve the problems that it is difficult to prepare nanosphere materials, not easy to prepare, and difficult to control the formation conditions of one-dimensional short rod stacking, etc., to achieve a simple and controllable process , Uniform shape, easy mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] The preparation method of this example comprises the following steps:

[0011] 1) Disperse and dissolve 0.989g of sodium tungstate in deionized water by ultrasonic for 30 minutes, and adjust the pH value of the above solution to 1.0 by adding 3mol / L hydrochloric acid drop by drop.

[0012] 2) Weigh 0.351g of sodium chloride particle powder with a molar ratio of 1:2 to sodium tungstate, slowly add the above solution as a mineralizer, and stir fully and uniformly for 30 minutes to obtain light yellow transparent and clear tungstic acid sol.

[0013] 3) Transfer the above-mentioned tungstic acid sol to a polytetrafluoroethylene reaction vessel with a capacity of 45 ml matched with a stainless steel hydrothermal kettle, and keep the filling degree at 75% for hydrothermal reaction. The working temperature of the hydrothermal reaction is 160 degrees Celsius. The time is 24 hours.

[0014] 4) Centrifuge the light yellow product obtained above, filter the supernatant by de...

Embodiment 2

[0016] The preparation method of this example comprises the following steps:

[0017] 1) Disperse and dissolve 1.980g of sodium tungstate in deionized water by ultrasonic for 30 minutes, and adjust the pH value of the above solution to 1.2 by adding 3mol / L hydrochloric acid drop by drop.

[0018] 2) Weigh 0.8766g of sodium chloride particle powder with a molar ratio of 1:2.5 to sodium tungstate, slowly add the above solution as a mineralizer, and stir fully and uniformly for 45 minutes to obtain light yellow transparent and clear tungstic acid sol.

[0019] 3) Transfer the above-mentioned tungstic acid sol to a polytetrafluoroethylene reaction vessel with a capacity of 100 ml matched with a stainless steel hydrothermal kettle, and keep the filling degree at 90% for hydrothermal reaction. The working temperature of the hydrothermal reaction is 180 degrees Celsius. The time is 24 hours.

[0020] 4) Centrifuge the light yellow product obtained above, filter the supernatant b...

Embodiment 3

[0022] The preparation method of this example comprises the following steps:

[0023] 1) Disperse and dissolve 0.495g of sodium tungstate in deionized water by ultrasonic for 30 minutes, and adjust the pH value of the above solution to 1.1 by adding 3mol / L hydrochloric acid drop by drop.

[0024] 2) Weigh 0.219g of sodium chloride particle powder with a molar ratio of 1:2.5 to sodium tungstate, slowly add the above solution as a mineralizer, and stir fully and uniformly for 25 minutes to obtain light yellow transparent and clear tungstic acid sol.

[0025] 3) Transfer the above-mentioned tungstic acid sol to a polytetrafluoroethylene reaction vessel with a capacity of 25 ml matched with a stainless steel hydrothermal kettle, and keep the filling degree at 80% for hydrothermal reaction. The working temperature of the hydrothermal reaction is 160 degrees Celsius. The time is 24 hours.

[0026] 4) Centrifuge the light yellow product obtained above, filter the supernatant by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com