Environment-friendly cold-resistant polyvinyl chloride cable material and preparation method thereof

A polyvinyl chloride cable and polyvinyl chloride resin technology, applied in the direction of plastic/resin/wax insulators, organic insulators, etc., can solve the problems of non-environmental protection, poor impact resistance, cold resistance, and low-temperature impact performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The preparation process of cold-resistant polyvinyl chloride cable material of the present invention is as follows, and wherein raw material comprises as follows:

[0038] Polyvinyl chloride resin powder 50kg, dioctyl terephthalate 17kg, dioctyl adipate 17kg, chlorinated polyethylene 2kg, light active calcium carbonate 15kg, lubricant (zinc stearate, calcium stearate and PE wax mixture) 1kg, Ca-Zn composite stabilizer 3kg, antioxidant (antioxidant 1076) 0.2kg, pigment (carbon black) 1kg.

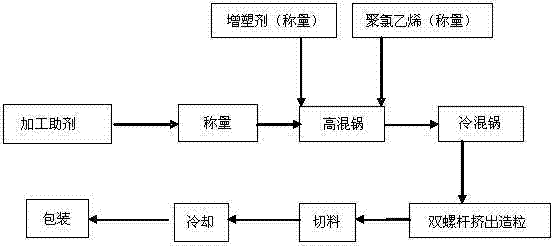

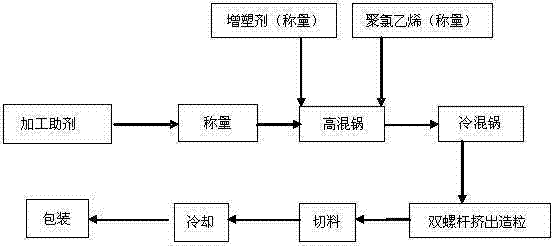

[0039] The preparation method of environment-friendly type cold-resistant polyvinyl chloride cable material of the present invention comprises the following steps:

[0040] 1) Weighing: Weigh each raw material according to the above dosage relationship.

[0041] 2) Mixing: First, add the weighed polyvinyl chloride resin powder and processing aids into the high mixing pot. The processing aids include: light active calcium carbonate, Ca-Zn composite stabilizer, chlorinated polyviny...

Embodiment 2

[0046] Raw materials: 60kg of polyvinyl chloride, 20kg of dioctyl terephthalate, 20kg of dioctyl adipate, 6kg of chlorinated polyethylene, 20kg of light activated calcium carbonate, lubricants (zinc stearate, calcium stearate and PE wax mixture) 2kg, Ca-Zn composite stabilizer 4kg, antioxidant (antioxidant 1076) 0.2kg, pigment (carbon black) 2kg.

[0047] The polyvinyl chloride cable material was prepared according to the method described in Example 1.

Embodiment 3

[0049] Raw materials: 40kg of polyvinyl chloride, 10kg of dioctyl terephthalate, 20kg of dioctyl adipate, 8kg of chlorinated polyethylene, 10kg of light activated calcium carbonate, lubricants (zinc stearate, calcium stearate and PE wax mixture) 3kg, Ca-Zn composite stabilizer 6kg, antioxidant (antioxidant 1076) 0.2kg, pigment (carbon black) 1.5kg.

[0050] The polyvinyl chloride cable material was prepared according to the method described in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com