Membrane bioreactor and microorganism fuel battery pack combination system

A technology of membrane bioreactor and fuel cell group, which is applied in the field of water treatment, can solve the problems of high electric field treatment cost, etc., achieve the effect of reducing treatment cost, good and stable operation effect, and realizing synergistic treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

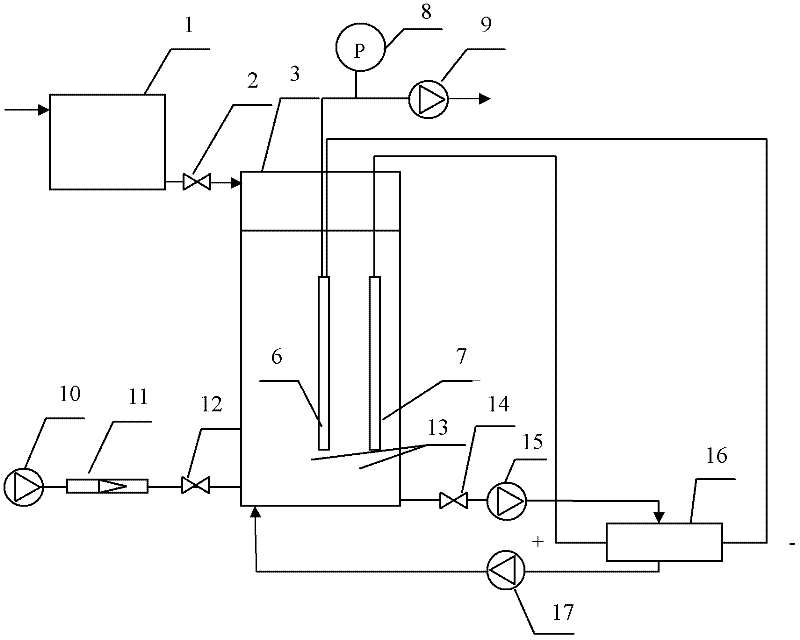

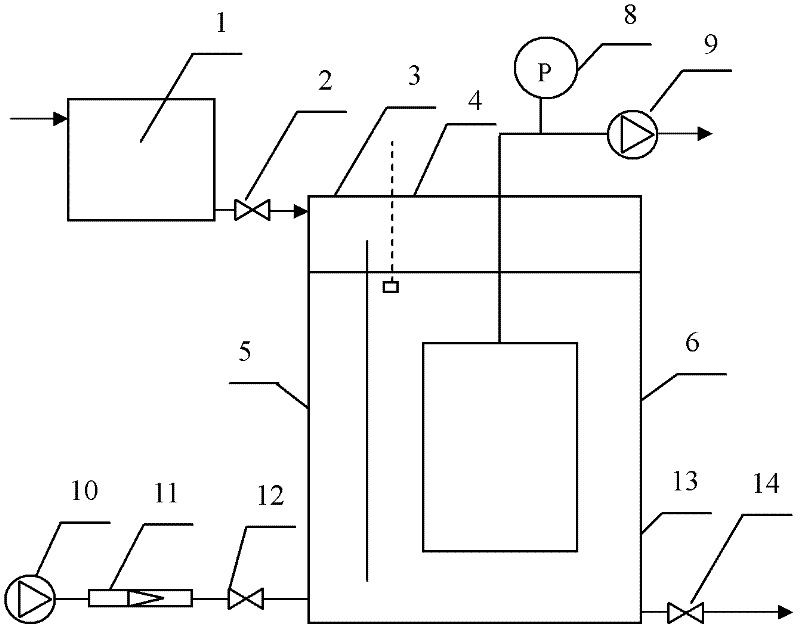

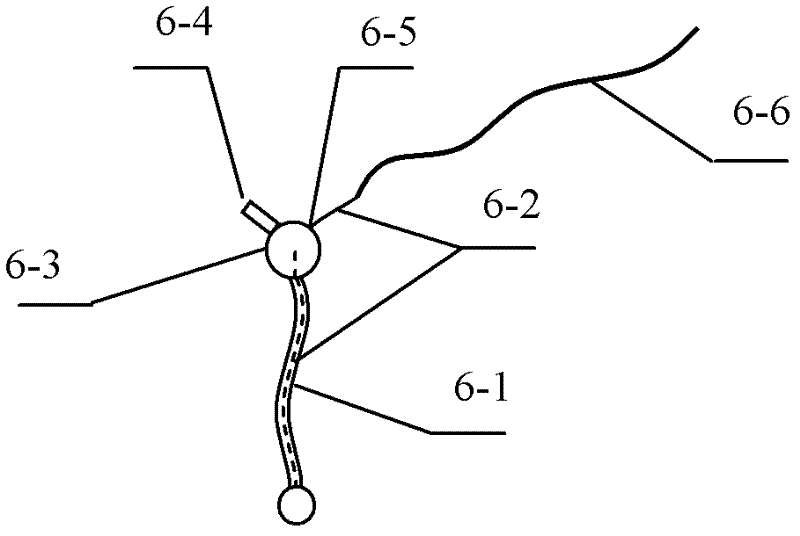

[0016] Specific implementation mode one: combine Figure 1-Figure 5 To illustrate this embodiment, the system includes a high-level water tank 1, a valve 2, a vacuum pressure gauge 8, a peristaltic pump 9 and a sludge discharge valve 14, and the high-level water tank 1 communicates with the water inlet of the membrane bioreactor 3 through the valve 2, and the system It also includes membrane bioreactor 3, membrane module 6, stainless steel mesh or titanium metal mesh 7, first sludge discharge pump 15, microbial fuel cell group 16 and second sludge discharge pump 17, membrane module 6 and stainless steel mesh or titanium metal mesh 7 is set in the membrane bioreactor 3, and the membrane module 6 is composed of a water collection pipe 6-3, a wire 6-6, a plurality of membrane filaments 6-1 and a plurality of first titanium filaments 6-2, and a plurality of membrane filaments 6- 1 Connected to the water collection pipe 6-3, the water collection pipe 6-3 is provided with a water ou...

specific Embodiment approach 2

[0017] Specific implementation mode two: combination Figure 4 and Figure 5 Describe this embodiment, the microbial fuel cell group 16 of this embodiment is made up of a plurality of microbial fuel cells connected in series or in parallel, each microbial fuel cell includes an anode 18, a cathode 19 and a container 26, and the top of the container 26 is provided with a reference electrode plug. Hole 21 and mud inlet 22, the bottom of container 26 is provided with mud discharge port 25;

[0018] The cathode and anode materials of each microbial fuel cell MFC are carbon cloth. 2 . Through the first sludge discharge pump 15, the remaining sludge of the membrane bioreactor MBR enters through the MFC sludge inlet 22, stays in the MFC for 5 days, and is discharged from the sludge discharge port 25 through the second sludge discharge pump 17. When using the reference electrode, the reference electrode is inserted into the rubber plug with holes, and then inserted into the referenc...

specific Embodiment approach 3

[0020] Specific implementation mode three: combination figure 1 Describe this embodiment, the system of this embodiment also includes rotor 23 and magnetic force stirrer 24, is provided with rotor 23 in container 26, and container 26 is arranged on the top of magnetic force stirrer 24, and magnetic force stirrer 24 is connected with rotor 23 by magnetic rotation . Other implementation modes are the same as the specific implementation mode 1 or 2.

[0021] Specific implementation mode four: combination figure 1 and figure 2Describe this embodiment, the system of this embodiment also comprises air pump 10, gas flow meter 11, valve 12 and aeration device 13, and air pump 10, gas flow meter 11, valve 12 and aeration device 13 are communicated through pipeline successively, aeration The aeration device 13 is arranged at the bottom of the membrane bioreactor 3 , and the aeration device 13 is composed of two aeration strips, which supply oxygen to the microorganisms and purge the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com