Strand oscillator for hose pipe winder

A technology of winding machine and cable arrangement, which is applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc. It can solve the problems of unwinding work, high damage rate of plastic hoses, and high labor intensity of workers, etc. Problems, to achieve the effect of neat and uniform arrangement, reduce labor intensity, and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and embodiment, further elaborate the present invention.

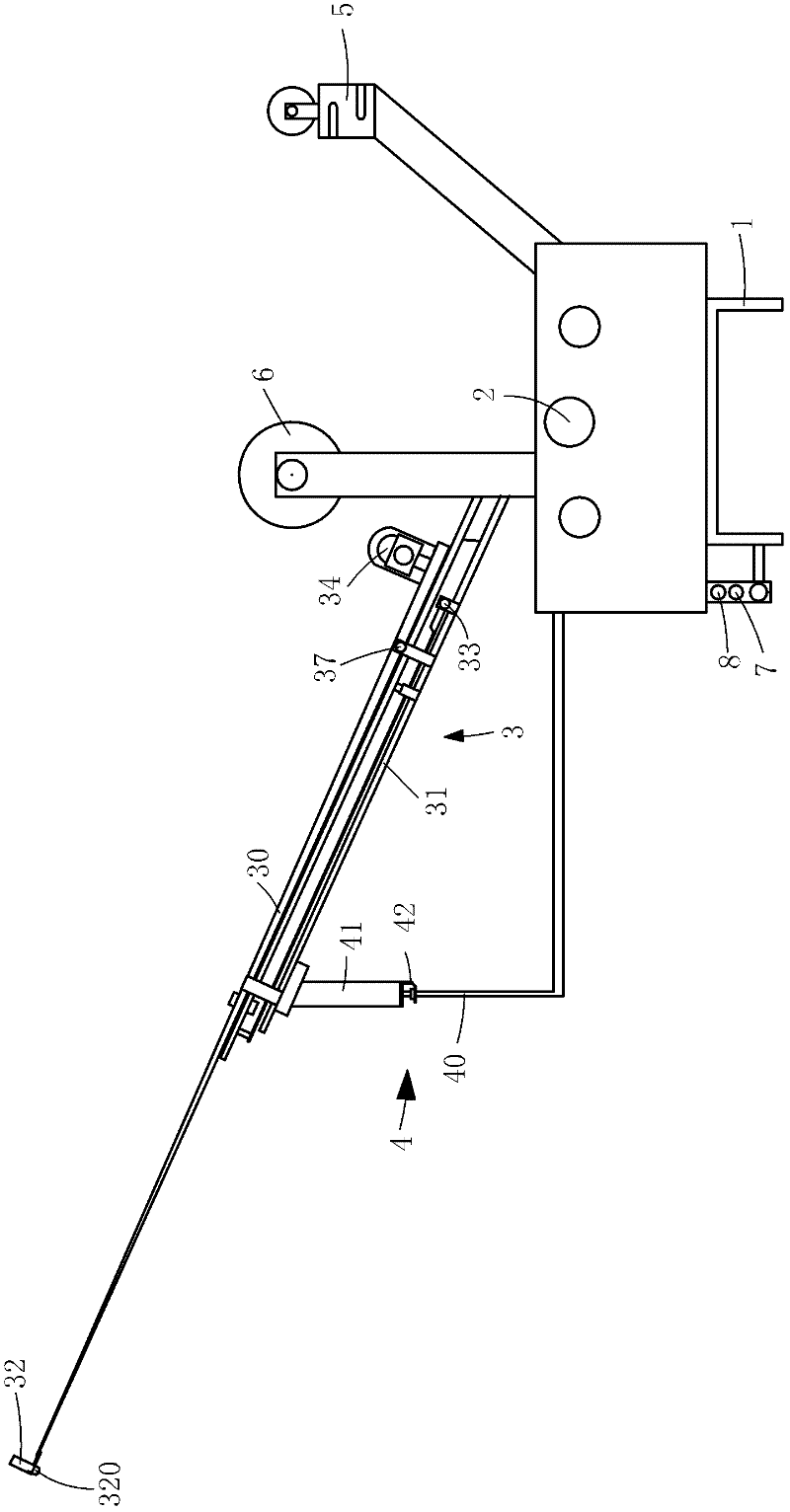

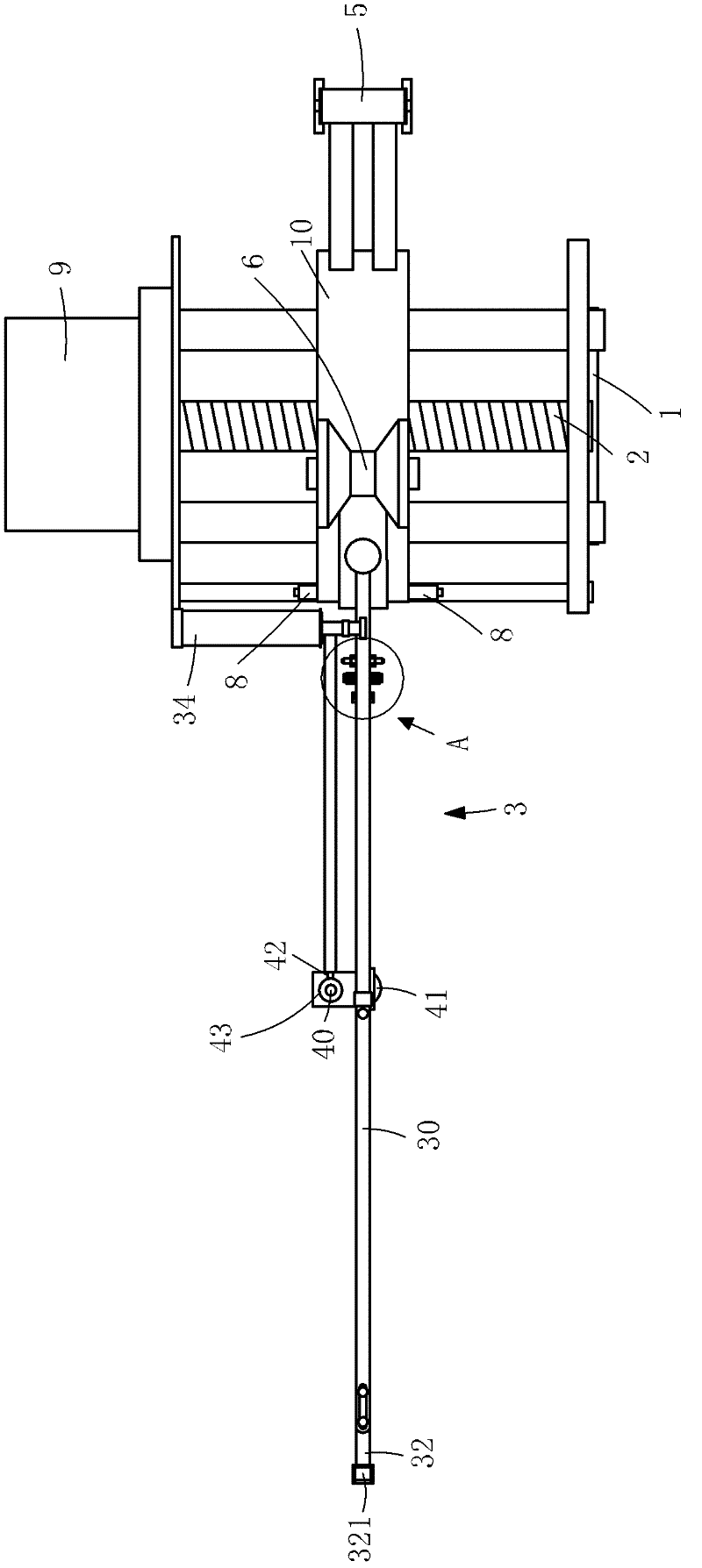

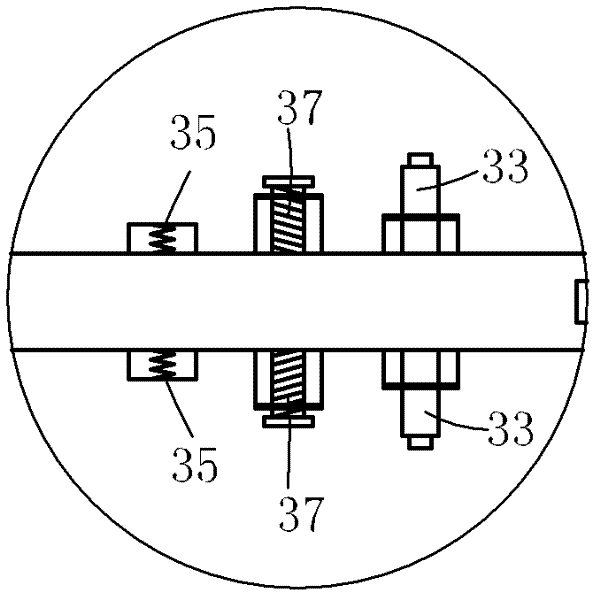

[0026] Such as figure 1 , figure 2 , image 3 and Figure 4 Commonly shown, a hose winder for a cable, including a bracket 1 installed on the winder frame 13, one side of the bracket 1 is provided with a limit sensor 8 opposite, the bracket 1 is provided with The cable screw 2, the cable screw 2 is driven by the power unit 9, the cable screw 2 is provided with a sliding seat 10 that can reciprocate along the cable screw 2 according to the signal output by the limit sensor 8, the sliding seat 10 There are guide wheels 6 and a cable assembly 3 for evenly arranging the hose 14 on the winding roller 12 of the winding machine; the cable winding device for the hose winding machine also includes an electrical control device. The hoses 14 can be automatically and evenly arranged on the winding roller 12 of the winding machine, avoiding the occurrence of overlapping of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com