Multifunctional laser processing head

A laser processing head and scanning galvanometer technology, applied in metal processing equipment, laser welding equipment, manufacturing tools, etc., can solve the problems of fine micromachining accuracy and quality deterioration, inability to use processing nozzles, and lack of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

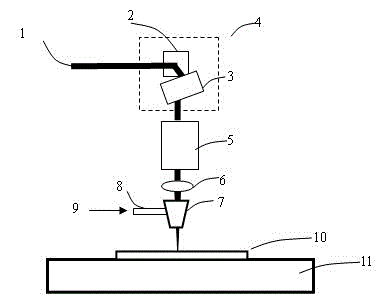

[0026] use as figure 1 For the laser processing head shown, the exit diameter of the processing nozzle is 0.5 mm, the focal length of the scanning focusing lens is 100 mm, and the distance between the focusing lens and the mirror in the two-dimensional scanning galvanometer is 240 mm; the processing inlet diameter is 500 microns and The tapered ceramic nozzle with an outlet diameter of 200 microns and a thickness of 0.5 mm uses an xy two-dimensional scanning galvanometer to perform variable-diameter laser cutting and etching on ceramics, and at the same time inputs high-pressure nitrogen to discharge the slag generated by laser etching. This method not only meets the size requirements of high-precision machining, but also eliminates the remelted layer on the inner hole wall, thereby eradicating the source of micro-cracks and greatly improving the quality of laser processing.

example 2

[0028] use as figure 1The laser processing head shown, the laser processing head processes 100×100 array microholes with a diameter of 80 microns on a 100 micron thick stainless steel sheet, the exit diameter of the processing nozzle is 0.2 mm, the focal length of the scanning focusing lens is 50 mm, and the focusing lens The distance from the reflector in the two-dimensional scanning galvanometer is 120mm; while the xy two-dimensional scanning galvanometer is used to cut holes on the stainless steel sheet in flight, the high-pressure inert argon gas is input to discharge the slag generated by laser etching. The method not only realizes high-precision and fast and efficient processing, but also avoids oxidation of the laser processing area, completely eliminates the phenomenon of slag hanging at the bottom of the laser incision, and improves the processing quality.

example 3

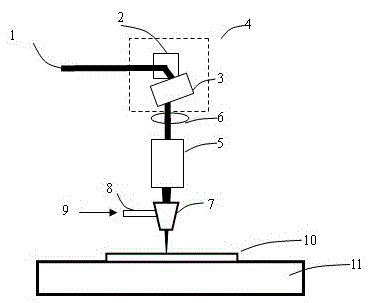

[0030] use as figure 2 For the laser processing head shown, the outlet diameter of the processing nozzle is 1 mm, the focal length of the general focusing lens is 200 mm, and the distance between the focusing lens and the mirror in the two-dimensional scanning galvanometer is 350 mm; the welding diameter of the laser processing head is 600 microns And the stainless steel sheet micro-sealed cover with a thickness of 0.1mm, while using the xy two-dimensional scanning galvanometer to quickly scan and weld the stainless steel sheet micro-sealed cover, input argon gas to protect the laser weld area from being oxidized. This method not only meets the sealing requirements Quality requirements, and because of the fast welding speed, thermal deformation of the stainless steel sheet micro-sealed cover is prevented, and the efficiency of laser welding is improved at the same time.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com