Double four-roll temper mill

A technology of skin pass mill and No. 1, which is applied in metal processing equipment, metal rolling, manufacturing tools, etc., can solve the problems of difficult installation, difficult belt threading, and reduced yield, saving initial investment and production costs, Good application and promotion prospects, and the effect of easy assurance of assembly accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in detail below in conjunction with the accompanying drawings.

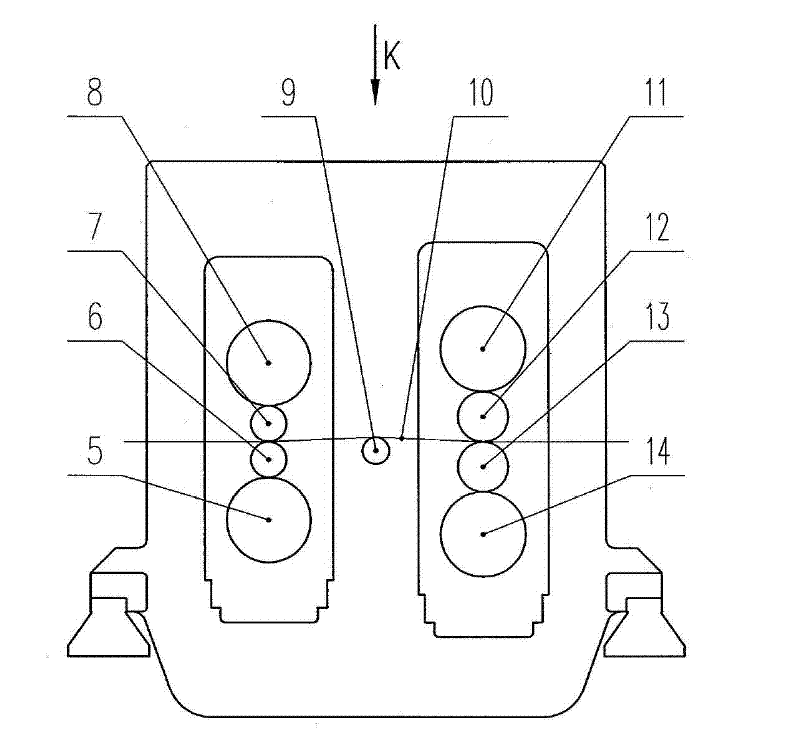

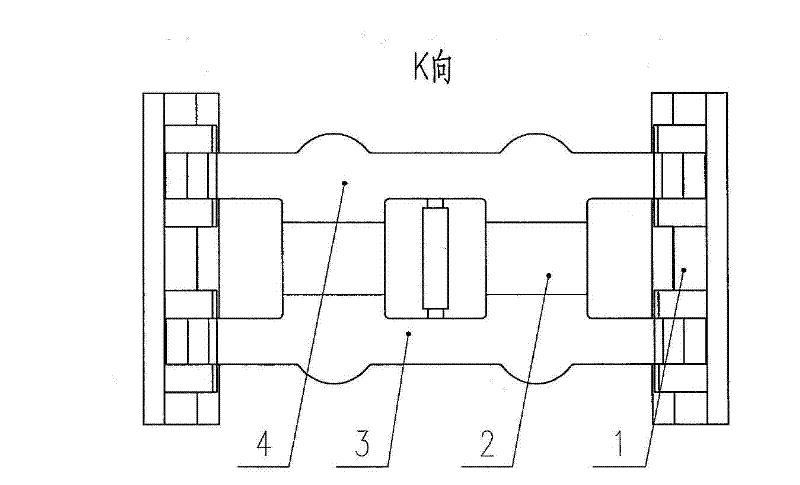

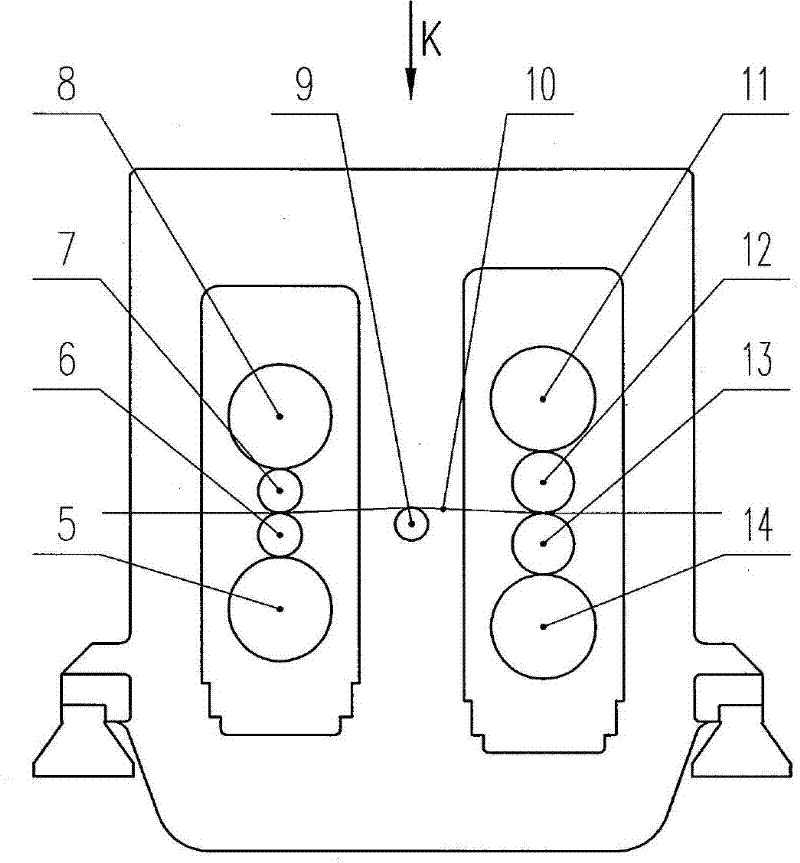

[0010] refer to figure 1 and figure 2 , a double four-roller skin pass machine, including a rail base 1, a beam 2, an operating side frame 3, a transmission side frame 4, a No. 1 four-roller system, a tension measuring roller 9, a No. 2 four-roller system, The No. 4 roll system includes the No. 1 lower backup roll 5, the No. 1 lower work roll 6, the No. 1 upper work roll 7 and the No. 1 upper backup roll 8, the No. 1 lower backup roll 5, the No. The work roll 7 and the No. 1 upper support roll 8 fall together from bottom to top in order to form the No. 1 four-roll roll system; the No. 2 four-roll roll system includes the No. 2 lower support roll 14, the No. 2 lower work roll 13, No. 2 upper work roll 12 and No. 2 upper back-up roll 11, No. 2 lower back-up roll 14, No. 2 lower work roll 13, No. 2 upper work roll 12 and No. 2 upper back-up roll 11 fall together from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com