Method for producing polyvinyl alcohol laminated paper, polyvinyl alcohol laminated paper and cosmetic box

A technology of polyvinyl alcohol and its manufacturing method, which is applied in the direction of chemical instruments and methods, boxes, coatings, etc., can solve the problems of non-hygroscopicity, concave curvature, etc., and achieve the effects of easy recycling, cost reduction, and excellent quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

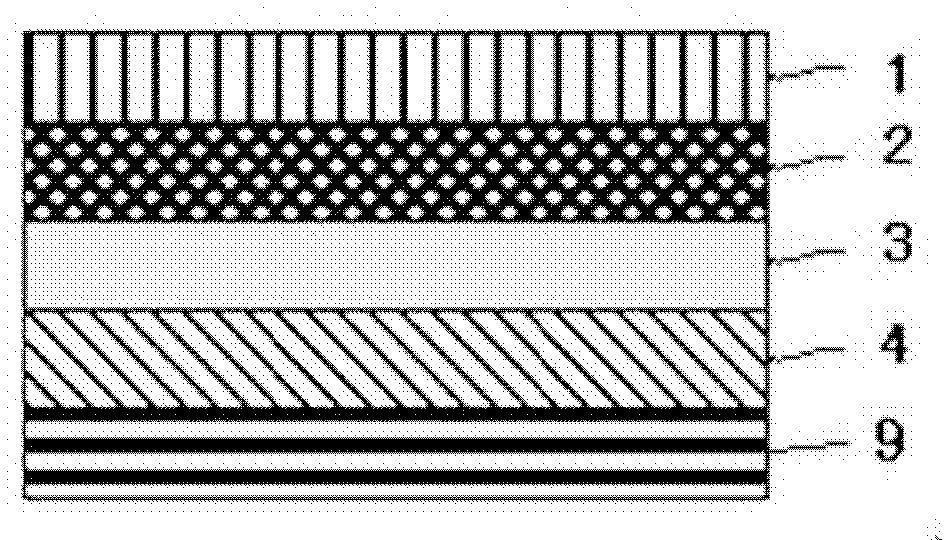

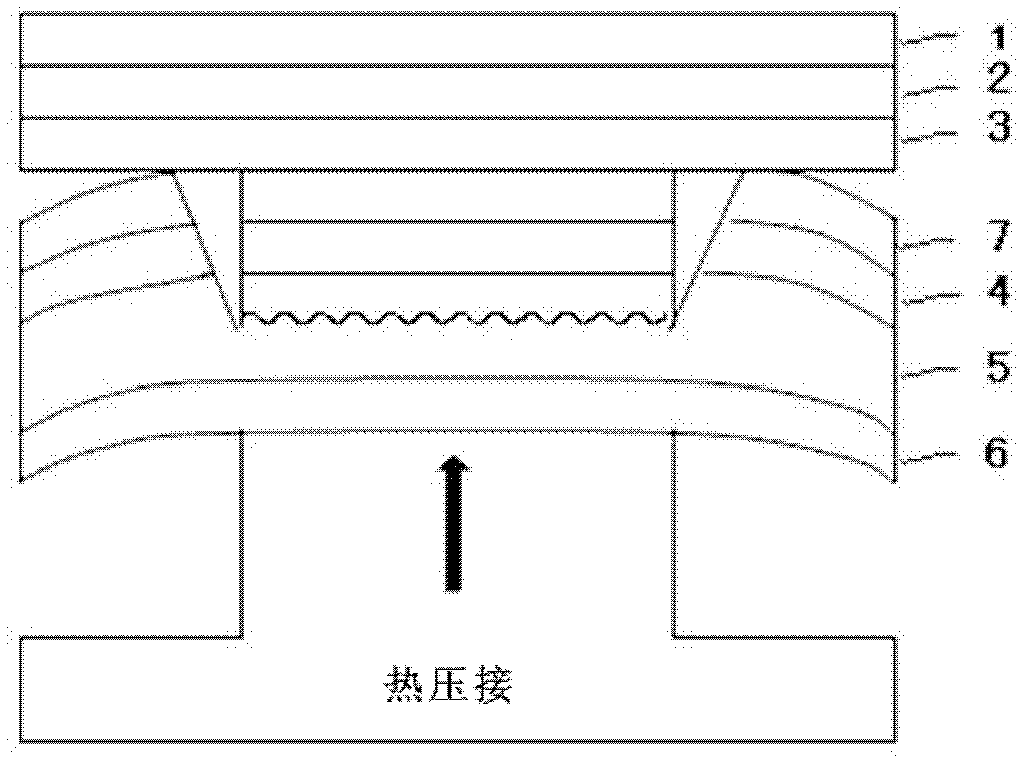

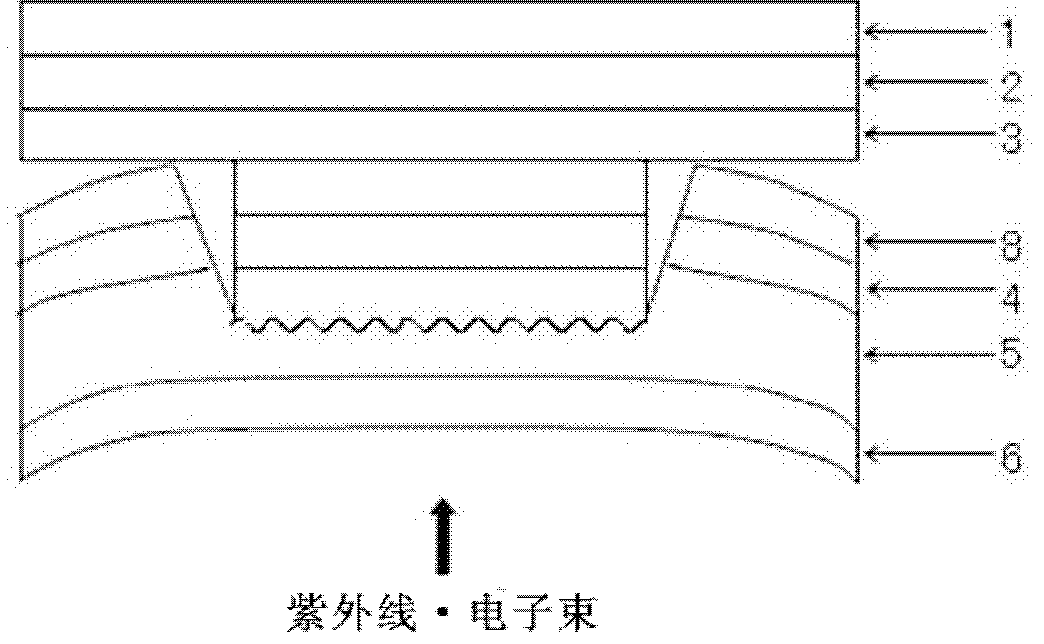

[0054] The use width is 800mm, the basis weight is 279g / m 2 Cast-coated paper ("GLORIA" made by Gojo Paper) as the base paper, and vacuum-plated aluminum on the PVA film ("BOVLON" (thickness 12μm) made by Nippon Gosei), and then the PVA film is vacuum deposited here Above, using a wet laminator, the coating amount of the coating as the adhesive is 3g / m 2 Ethylene-vinyl acetate copolymer resin ("DB314" manufactured by Saiden Chemicals (53% concentration, 500mPa·s)), and then the PVA film surface is bonded to the coated surface of the cast-coated paper to protect the aluminized surface Use a gravure coater to coat a polyester primer ("UVprimer" made by DIC) with a thickness of 1μm to provide a primer layer, and then dry to obtain polyethylene Alcohol laminated paper. At this time, the laminator speed was 100m / min, and the drying temperature was 90°C.

[0055] Five colors (white, black, blue, red, yellow) are printed on the above-mentioned polyvinyl alcohol laminated paper using a ...

Embodiment 2

[0057] The use width is 800mm, and the basis weight is 310g / m 2 Coated paper ("JET ACE" made by Japan's Daishow Paperboard) as the backing paper, using a wet laminator, vacuum-plated aluminum on the PVA film ("BOVLON" made by Nippon Gosei (12μm thick)), and On the vacuum-plated PVA film, using a wet laminator, the coating amount as a binder is 4g / m 2 Acrylic copolymer resin (Saiden Chemical "PZ905" (concentration 47%, viscosity 1,250mPa·s)), and then the PVA film surface and the coated surface of the coated paper are laminated to protect the vaporization of the aluminum-plated surface For plating and improving printability, a gravure coater was used to coat the same polyester primer ("UV primer" made by DIC) with a thickness of 1 μm as in Example 1 to provide a primer layer, and then dried to obtain polyethylene Alcohol laminated paper. At this time, the laminator speed was 100m / min, and the drying temperature was 90°C.

[0058] After printing on the above-mentioned polyvinyl al...

Embodiment 3

[0061] The use width is 800mm, the basis weight is 315g / m 2 The cast-coated paper (GLORIA, manufactured by Gojo Paper Co., Ltd.) was used as the base paper, and the PVA film ("BOVLON" (thickness 14μm) manufactured by Nippon Gosei) was coated as the adhesive coating using a wet laminator The amount is 5g / m 2 Ethylene-vinyl acetate copolymer resin (Konishi "SP2850" (51% concentration, viscosity 3,000mPa·s)), the PVA film surface is bonded to the coated surface of the cast-coated paper, dried and rolled into a roll , Thereby forming a laminated paper of PVA film and coated paper. Use a foil ("NAFTAP" manufactured by Nakai Kogyo Co., Ltd.) with a peeling layer on a 12μm polyethylene terephthalate film and vacuum aluminum plating as the transfer foil, and the coating amount on the vapor deposition surface of the transfer foil is 5g / m 2 , Use a gravure coater to coat the water-based dry laminating adhesive ("AP355" manufactured by Nisei Chemical Co., Ltd. (concentration: 45%, viscosi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com