Efficiency testing device and method for automobile clutch separating system

A technology of efficiency test and separation system, which is applied in the field of efficiency test device of automobile clutch separation system, which can solve problems such as unfavorable load efficiency and stroke efficiency of clutch separation system, influence on automobile power transmission, NVH performance, driver control comfort, error, etc. , to achieve the effect of improving NVH performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

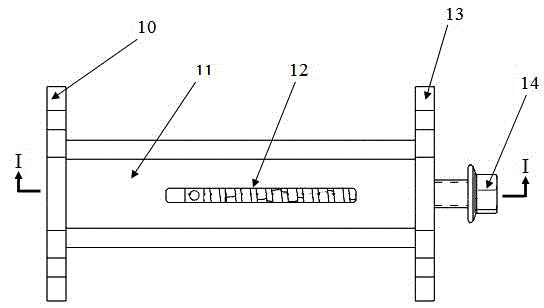

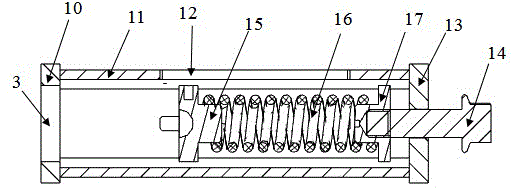

[0029] Below in conjunction with accompanying drawing, preferred embodiment of the present invention is described in further detail:

[0030] Such as figure 1 and figure 2 As shown, a kind of efficiency testing device of automobile clutch disengagement system, comprises the first connection plate 10, support tube 11 and the second connection plate 13 that are connected in sequence; and the second spring seat 17; the first spring seat 15, the spring 16 are connected with the second spring seat 17 in turn; the outer wall of the support tube 11 is also provided with a scale groove 12, and the length of the scale groove 12 is greater than or equal to that of the spring 16, the compression of the spring 15 can be fully seen through the scale groove 12; the first connection plate 10 is provided with a through hole 3, and the through hole 3 communicates with the support tube 11. In practical applications, in order to obtain the pressure and displacement of the spring 15 at any tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com