Composite bushing type water spraying desuperheater

A technology of spraying water for desuperheating and composite casing, which is applied in the control of superheat temperature, steam superheating, steam generation, etc., can solve the problems of cantilever vibration of nozzle device, crack of desuperheater liner, fracture of nozzle device, etc., to avoid Leakage defects and limitations of low temperature and low pressure use, ease of manufacturing and assembly, and enhanced recoil effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the present invention more comprehensible, a preferred embodiment is described in detail below with accompanying drawings.

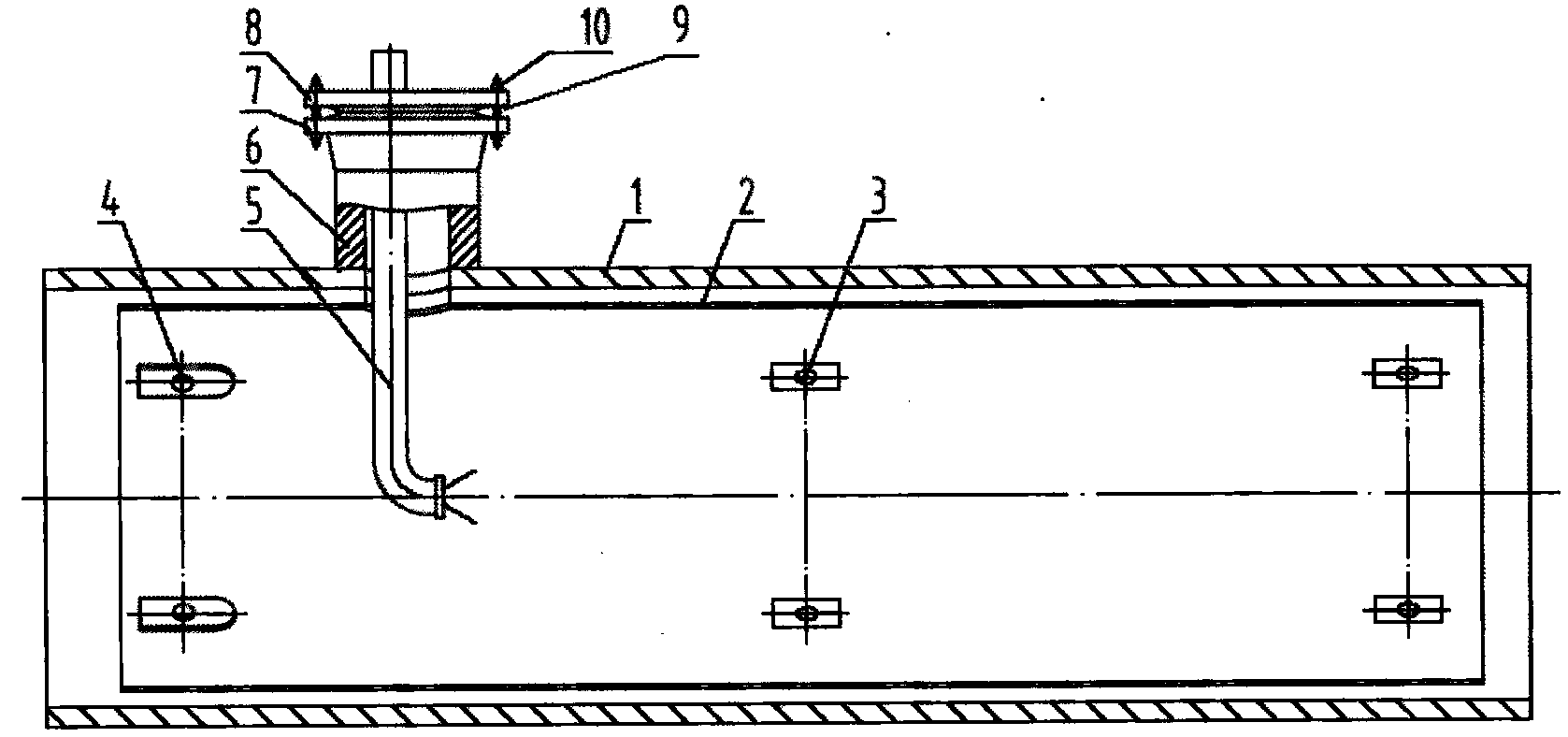

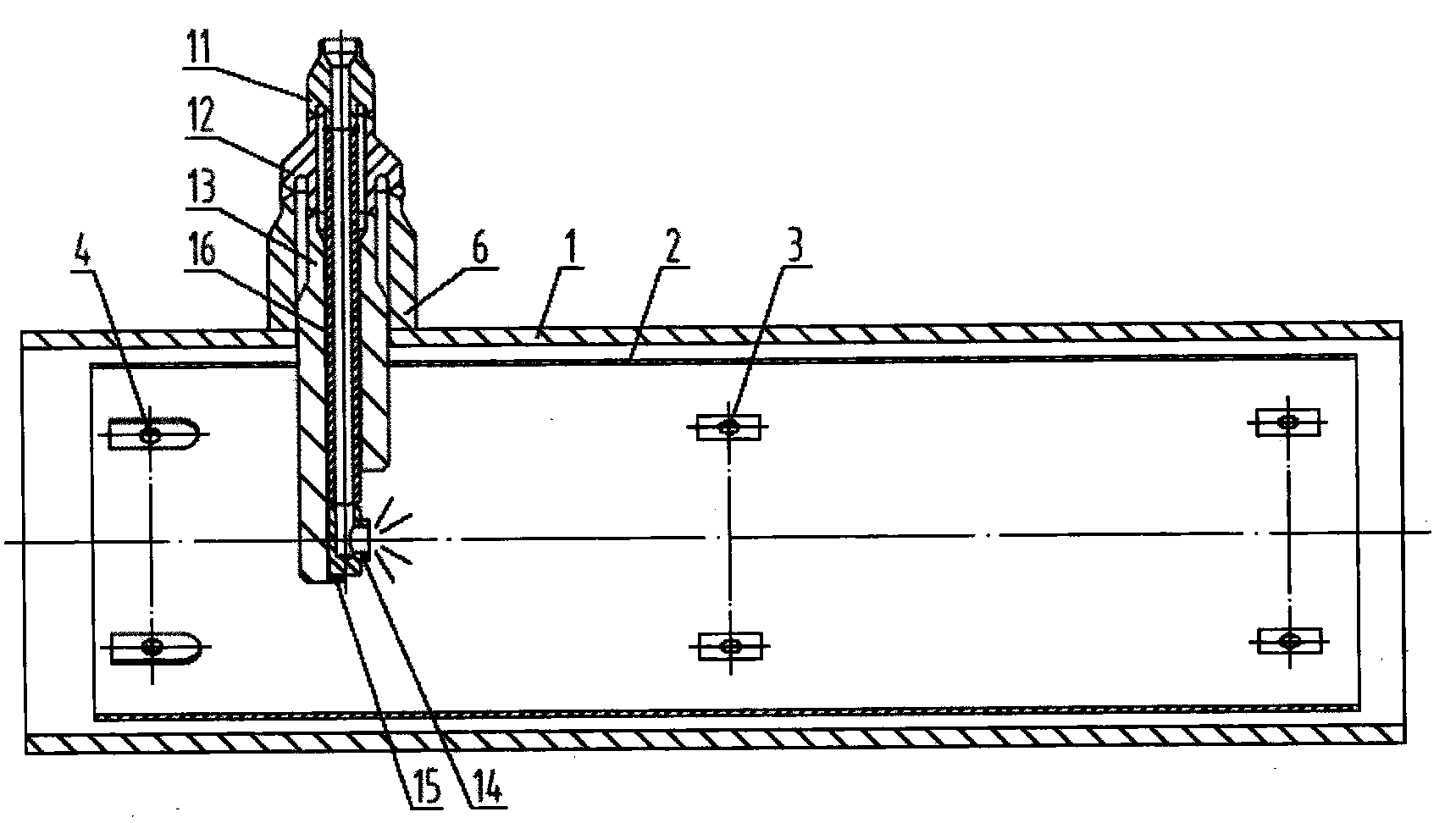

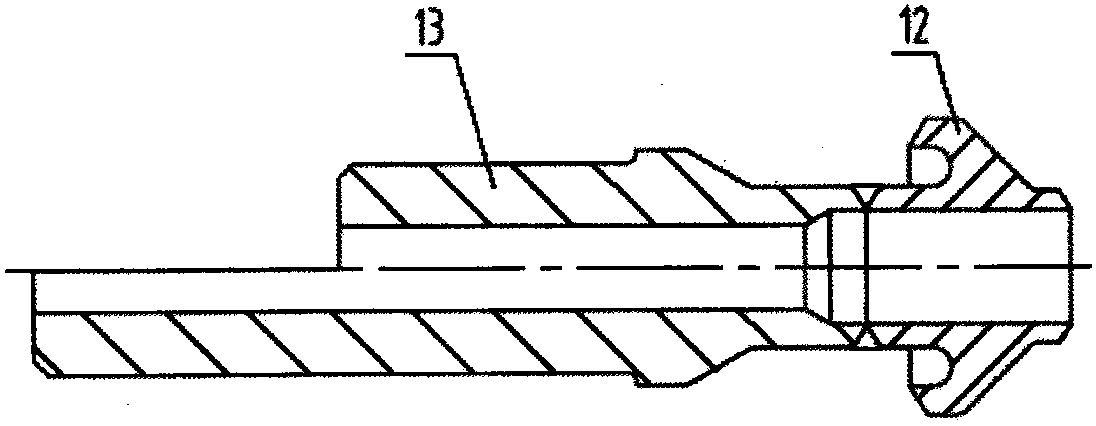

[0019] figure 2 It is a structural schematic diagram of a composite casing type water spray desuperheater provided by the present invention. The composite casing type water spray desuperheater is composed of a cylinder body 1, an inner bushing 2, a support bolt 3, and a fixing bolt 4 , the main body pipe seat 6, the inner layer of nozzle 11 of the composite pipe seat, the outer layer of nozzle 12 of the composite pipe seat, the nozzle strengthening protection pipe 13, the fixed support block 15 and the nozzle pipe 16.

[0020] The cylinder body 1 has an inner bushing 2 built in, and the inner bushing 2 is fixed by fixing bolts 4 and supported and positioned by support bolts 3 . One end of the inner bushing 2 is fixed in the axial direction of the desuperheater by the fixing bolt 4, and the other end of the inner bushing 2 is a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com