Lubricant composition of metal materials for water-based plastic processing

A lubricant composition, a technology for plastic working, applied in the directions of lubricant composition, petroleum industry, etc., to achieve the effects of simple formation, excellent film removal, and excellent rust resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6 and comparative example 1~2

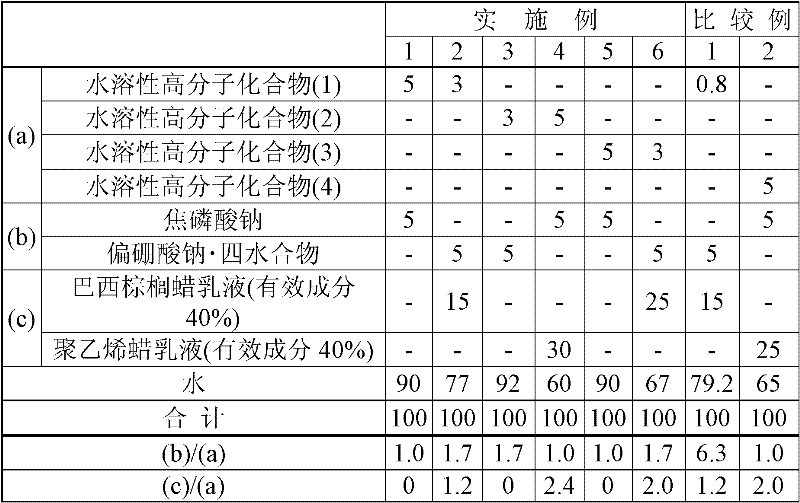

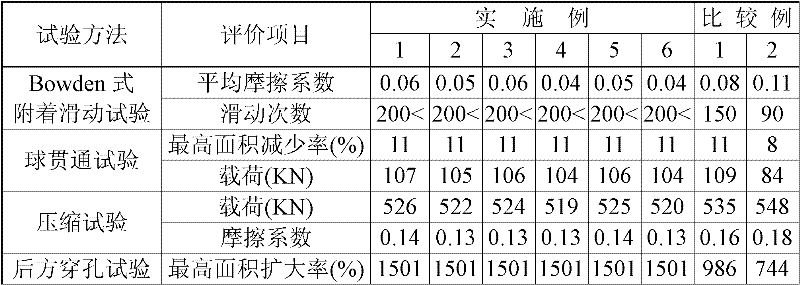

[0059] As shown in Table 1 below, (a) component (water-soluble polymer compound), (b) component (inorganic metal salt), (c) component (wax) and water were mixed to prepare examples 1 to 6 of the present invention. Water-based lubricant composition for plastic working and comparative water-based lubricant composition for plastic working of Comparative Examples 1-2.

[0060] The numerical value of the compounding quantity in a table shows component weight%.

[0061] Table 1

[0062]

[0063] In Table 1, the water-soluble polymer compound (1) is "ALKOX" (trade name, water-soluble polyether compound) manufactured by Meisei Chemical Industry Co., Ltd., and the water-soluble polymer compound (2) is manufactured by Sanyo Chemical Industry Co., Ltd. "MELPOL F-220" (trade name, water-soluble polyether compound), the water-soluble polymer compound (3) is "PAOGEN PP-15" (trade name, water-soluble polyester compound) manufactured by Daiichi Kogyo Pharmaceutical Co., Ltd. The water-so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com