Nickel powder with large furnace safety supervision system (FSSS) particle size and preparation method thereof

A nickel powder and particle size technology, which is applied in the field of large FSSS particle size nickel powder preparation, can solve the problems of uneven distribution, large nickel powder FSSS, and large power consumption, and achieve large particle size, low equipment requirements, and production efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

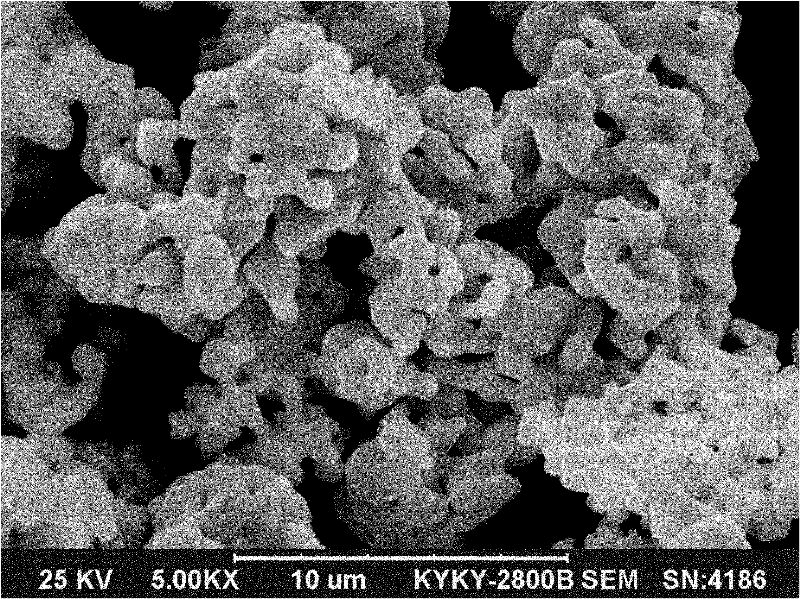

Image

Examples

preparation example Construction

[0014] The embodiment of the present invention provides a kind of preparation method of large FSSS nickel powder, comprises the following steps:

[0015] Step S01, reacting ammonium oxalate and nickel chloride for 10-30 minutes at a temperature of 50-60°C and a pH value of 1.5-3.0 to obtain nickel oxalate precipitation;

[0016] Step S02, subjecting the nickel oxalate precipitate to flash drying and crushing to obtain a nickel oxalate precursor;

[0017] Step S03, reducing the nickel oxalate precursor at a temperature of 450-550°C to obtain a nickel powder precursor;

[0018] Step S04, performing turbine crushing on the nickel powder precursor, and then performing airflow crushing to obtain nickel powder.

[0019] Specifically, the large FSSS particle size referred to in the embodiments of the present invention means that the FSSS particle size is greater than 3 microns.

[0020] Specifically, in step S01, the ammonium oxalate used is not limited, and can be commercially ava...

example

[0047] Prepare a 150g / L oxalic acid solution, add liquid ammonia, adjust the pH to 4.3 to obtain an ammonium oxalate solution, and keep the heating temperature at 70°C;

[0048] The ammonium oxalate solution is reacted with 90g / L nickel chloride solution in a reactor, the nickel chloride flow rate is controlled to be 1000-1500L / min, and the ammonium oxalate flow rate is 2500-3500L / min. Adjust the pH value of the reaction to 2.0, the reaction time is 12 minutes, age for 10 minutes, filter with a centrifuge, and wash with hot pure water at 80°C;

[0049] The washed nickel oxalate precipitate is subjected to flash drying and crushing treatment, and the flash drying and crushing machine can sort out some fine particles to obtain a nickel oxalate precursor with uniform particle size.

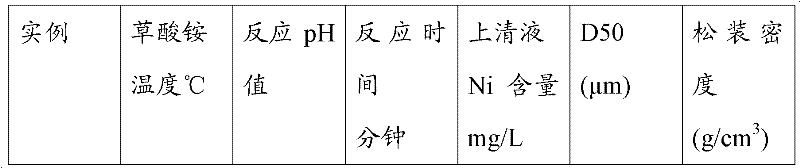

[0050] Change the reaction pH value, temperature, and reaction time to obtain nickel oxalate precursors with different particle sizes, as follows:

[0051]

[0052]

[0053] It can be conclude...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com