Electrical drive unit for a motor vehicle

An electric drive unit, vehicle technology, applied in the direction of electrical components, electric components, electromechanical devices, etc., can solve problems such as damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

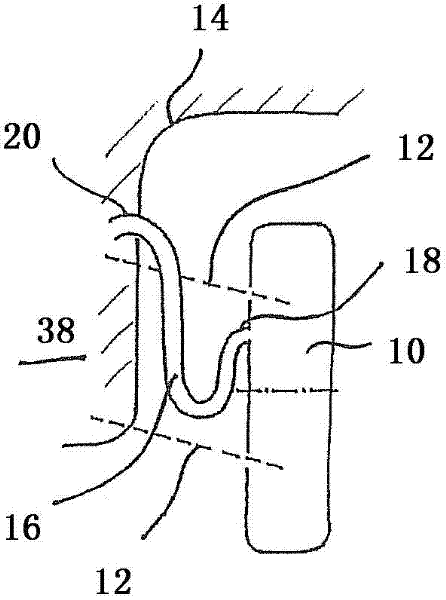

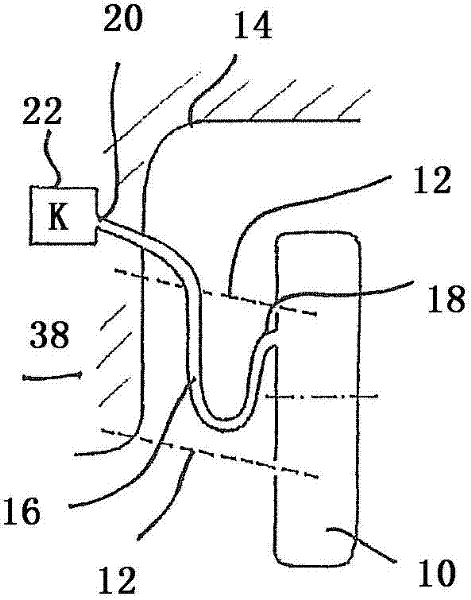

[0026] figure 1A first embodiment of an electric drive unit according to the invention is schematically shown with a hub drive arranged on a wheel 10 , not shown here, wherein the wheel 10 is fastened via a wheel suspension 12 to a wheel arch 14 of the vehicle. In order to be able to equalize the pressure between the interior of the wheel hub drive, which is sealed off by a seal (not shown here) and the environment, a ventilation device with an air duct 16 is provided. The air duct 16 is designed here in the form of a hose, which is guided from the interior of the wheel hub drive inside the wheel 10 via the wheel arch 14 into the interior 38 of the vehicle. In this case, a first end section 18 of the air line 16 leads into the interior of the wheel hub drive and a second end section 20 of the air line 16 , which is opposite the first end section 18 , leads. into the interior space 38 of the vehicle. The ventilation here takes place toward the vehicle interior 38 .

[0027] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com