Anodic capillary layer for beta battery and beta battery comprising same

A capillary layer, anode technology, applied in the direction of electrode carrier/current collector, secondary battery, circuit, etc., can solve the problems such as can not meet the actual large-scale application, high cost, complex technical process and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0039] The present invention is further described below in conjunction with specific examples. However, it should be understood that these examples are only used to illustrate the present invention and not to limit the scope of the present invention. The test methods for which specific conditions are not indicated in the following examples are generally in accordance with conventional conditions, or in accordance with the conditions suggested by the manufacturer. All percentages and parts are by weight unless otherwise indicated.

[0040] The beta-alumina and other solid electrolytes used in the following comparative examples and examples were all provided by the Institute of Ceramics, Chinese Academy of Sciences.

Embodiment 1

[0044] The cleaning conditions of Beta-alumina are the same as those of the comparative example. A porous metal nickel medium with a pore size of 5-10 μm is coated on the surface of beta-alumina by coating method to obtain a sample for testing the wetting angle.

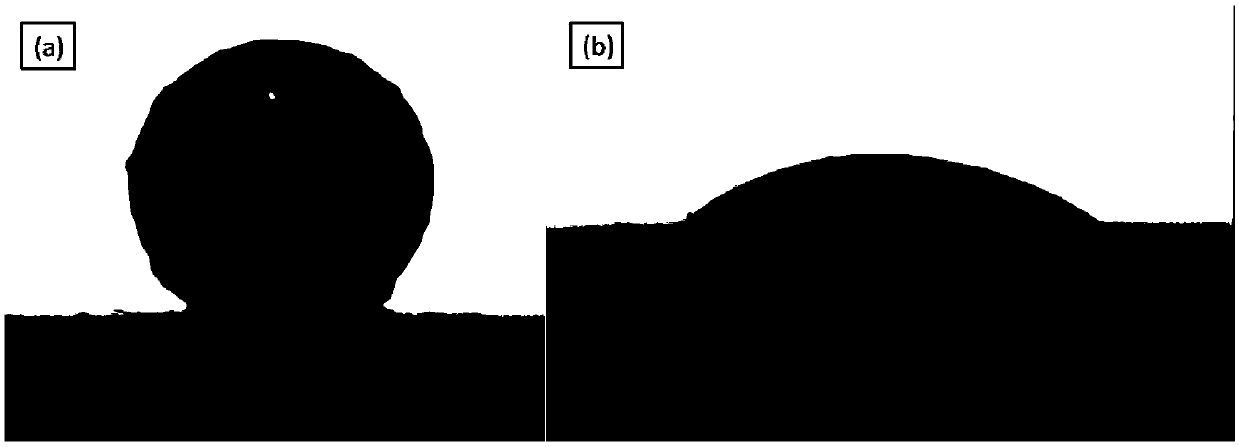

[0045] The wetting angle between the sample and sodium was tested according to the method of the comparative example, the test conditions were the same as the comparative example, and the test results are shown in Table 1 below. It can be seen from the data in Table 1 that the wetting angle between the beta-alumina sample coated with porous metal nickel medium obtained in this example and sodium is reduced by 73.5% compared with that before coating.

[0046] figure 1 It is a cross-sectional scanning electron photo of the porous metallic nickel medium coated on the surface of beta-alumina in this example. The thickness of the porous metal nickel medium in the figure is about 6 μm, showing a network structure.

[00...

Embodiment 2

[0049] The cleaning conditions of Beta-alumina are the same as those of the comparative example. A porous metal nickel medium with a pore size of 4-15 μm was coated on the surface of beta-alumina by casting method to obtain a sample for testing the wetting angle.

[0050] The wetting angle between the sample and sodium was tested according to the method of the comparative example, the test conditions were the same as the comparative example, and the test results are shown in Table 1 below. It can be seen from the data in Table 1 that the wetting angle between the beta-alumina sample coated with porous metal nickel medium obtained in this example and sodium is reduced by 76.8% compared with that before coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com