Double-station automatic pressing machine for primer of hunting shot

A press machine, double station technology, applied in the direction of ammunition, weapon accessories, offensive equipment, etc., can solve the problems of long upgrade cycle, high investment cost, high maintenance cost, and achieve compact structure, efficient power transmission, and high working frequency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

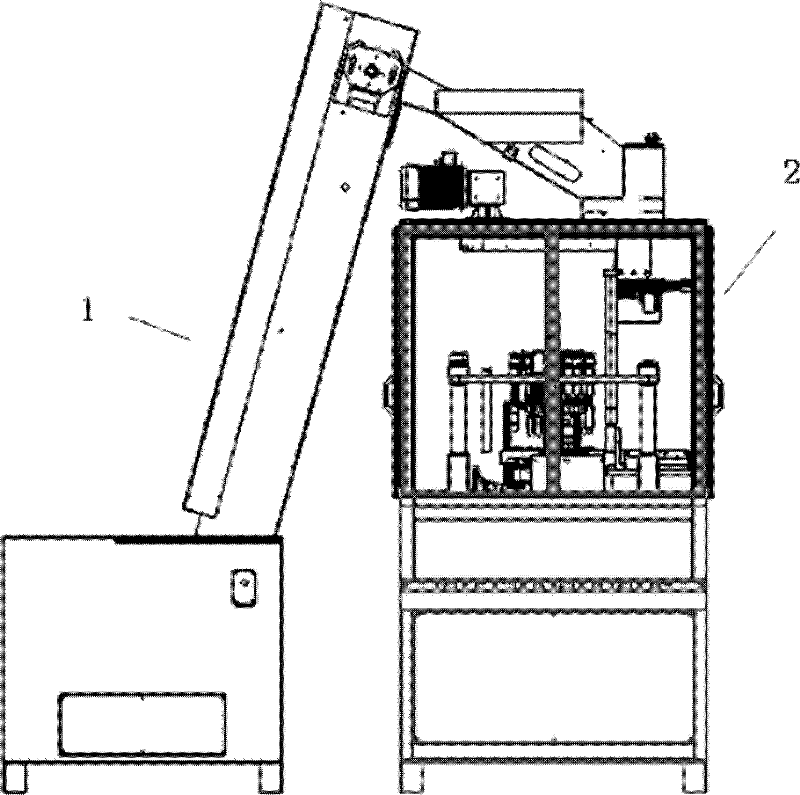

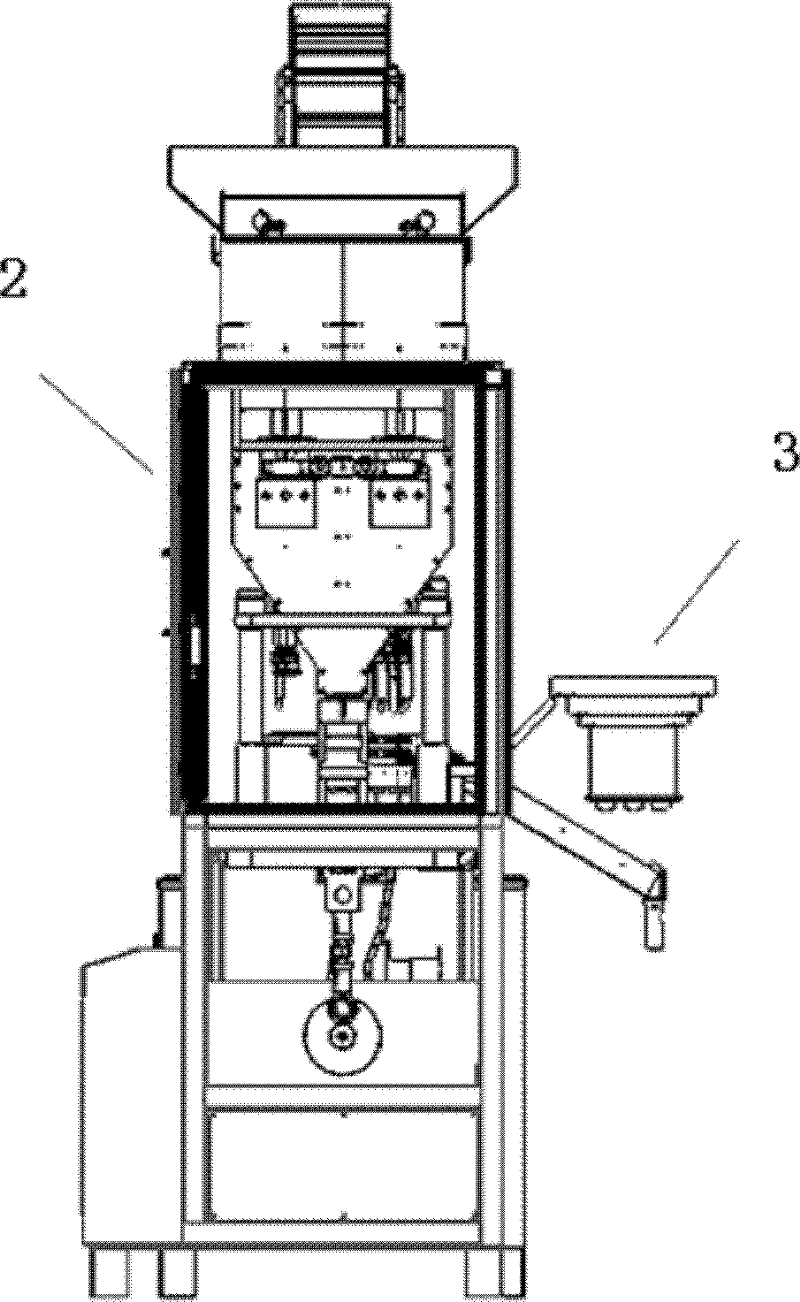

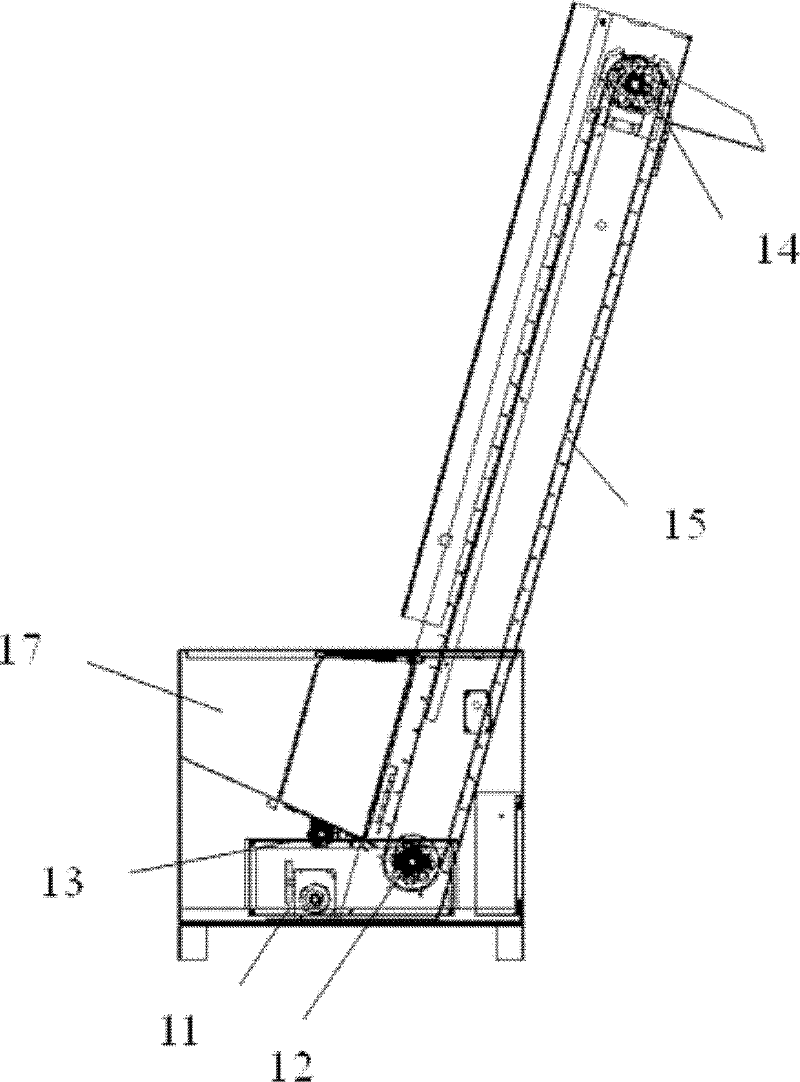

[0036] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the double-station automatic press-fitting machine for hunting and priming of the present invention includes a shell hoist 1, a primer conveyor 3 and a press-fitting machine 2, and the above-mentioned shell hoist 1 includes an explosion-proof motor 11, a right-angle flange reducer, a sprocket chain 12, Vibration wheel set 13, drum 14, conveyor belt 15, thin steel sheet set 16 and cartridge housing 17, the output end of the above-mentioned explosion-proof motor and right-angle flange reducer are respectively connected with the drum 14 and the vibration wheel set 13 through the sprocket chain 12 , the cartridge case placement bin 17 has an inclined bottom, the vibrating wheel group 13 is in contact with the thin steel sheet group 16, and the roller 14 is provided with a conveyor belt 15 for conveying the cartridge cases; the above-mentioned primer conveyor 3 includes a vibrating plate 31 and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com