Heat exchange device for adjusting temperature of loose solid particles

A loose solid, heat exchange device technology, applied in the direction of heat exchanger type, heat exchanger shell, direct contact heat exchanger, etc., to achieve the effect of remarkable effect, obvious effect and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (Example 1, a heat exchange device for regulating the temperature of loose solid particles)

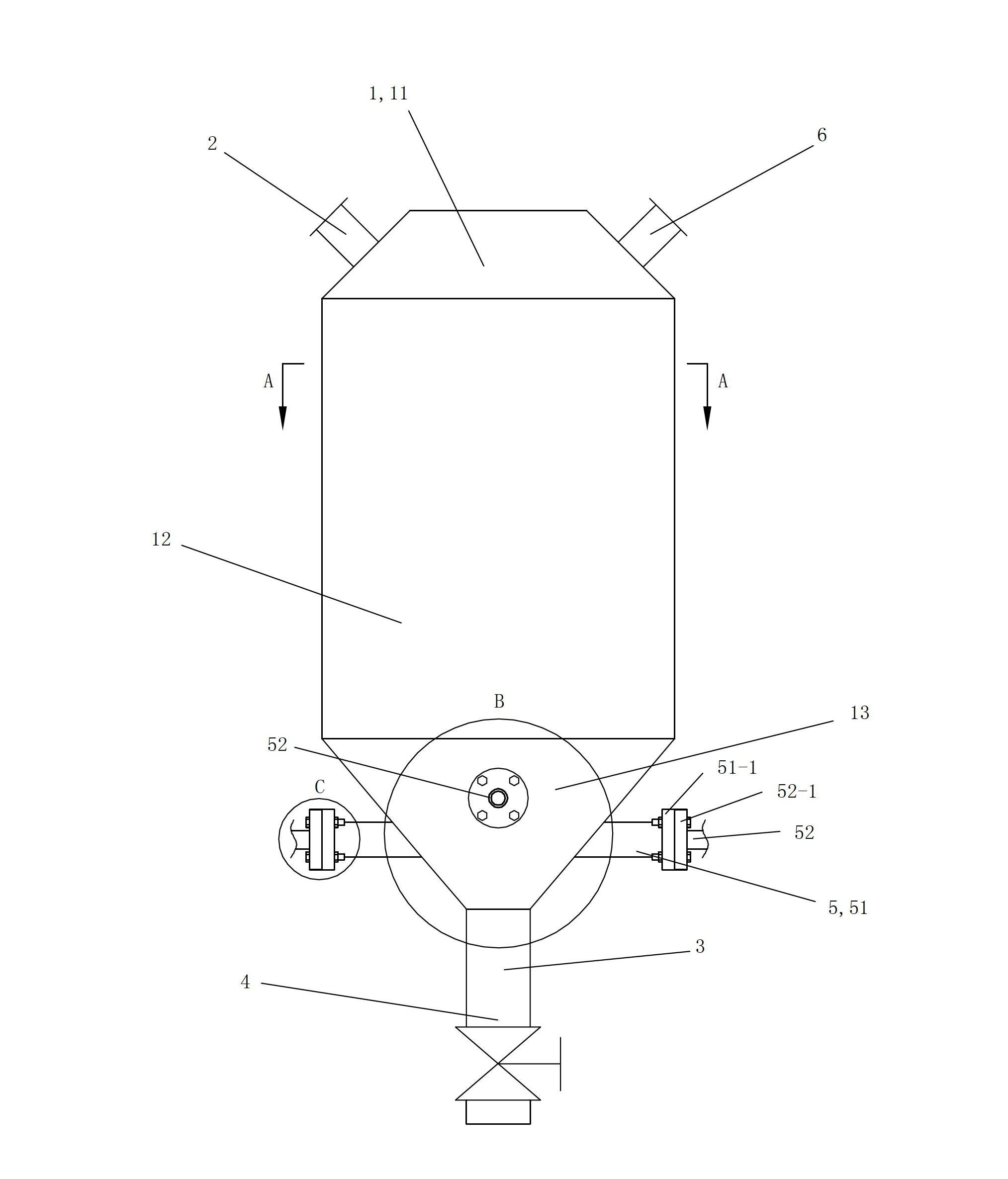

[0036] See figure 1 , The device for regulating the temperature of loose solid particles in this embodiment includes a temperature regulating bin 1 , a feed inlet 2 , a discharge port 3 , a valve 4 , an air inlet device 5 and an air outlet 6 .

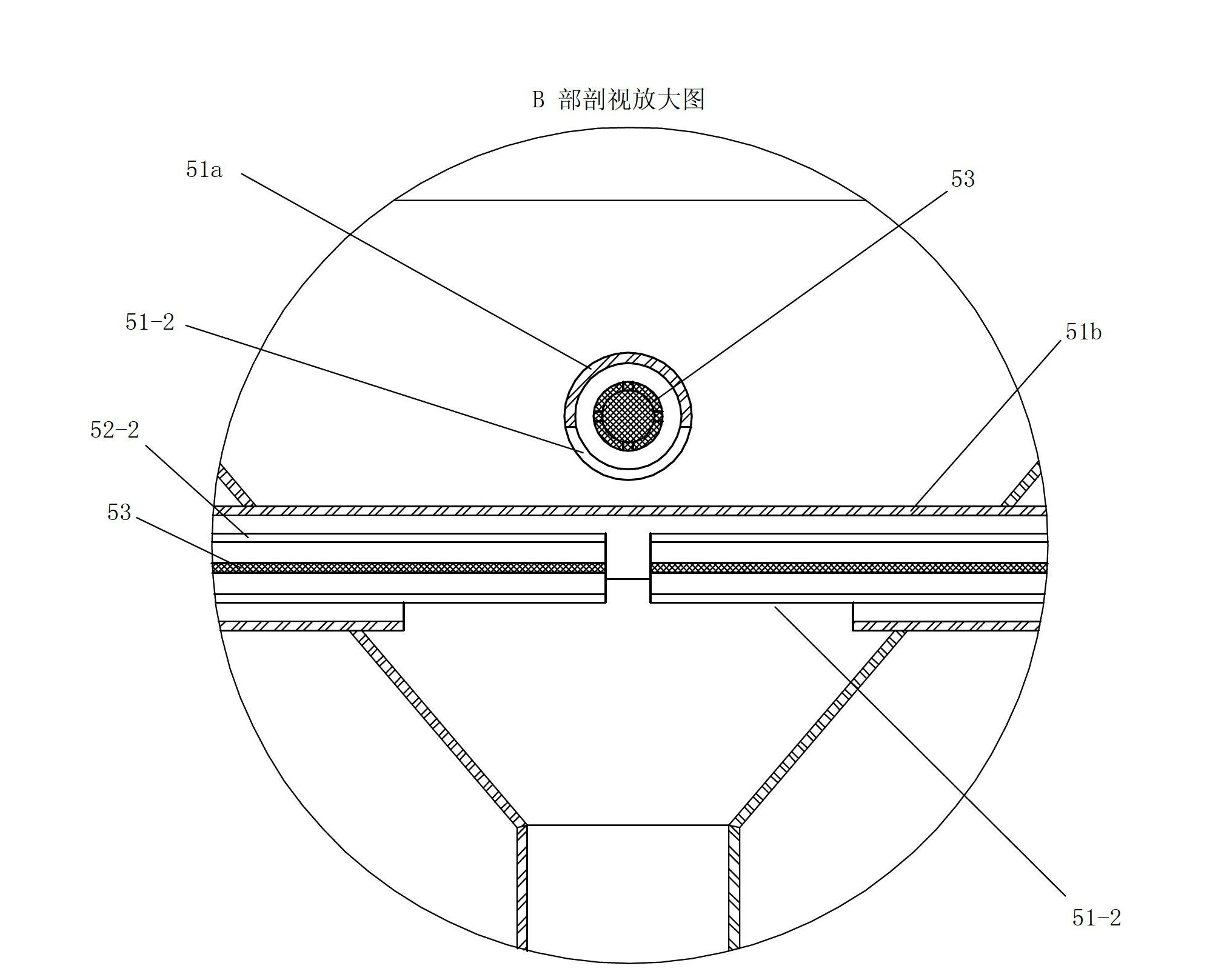

[0037] See figure 1 , There is basically no obstruction in the temperature adjustment chamber 1, and the temperature adjustment chamber 1 is divided into a preheat exchange section 11, a heat exchange section 12 and a rapid heat exchange section 13 from top to bottom. The preheat exchange section 11 is a circular frustum shell with an opening downward, and there is no barrier in the inner cavity of the circular cone shell; the heat exchange section 12 is a cylindrical shell, and there is no barrier in the inner cavity of the cylindrical shell; the heat exchange The upper opening of the cylindrical shell of section 12 corresponds to th...

Embodiment 2

[0040] (Example 2, a heat exchange device for regulating the temperature of loose solid particles)

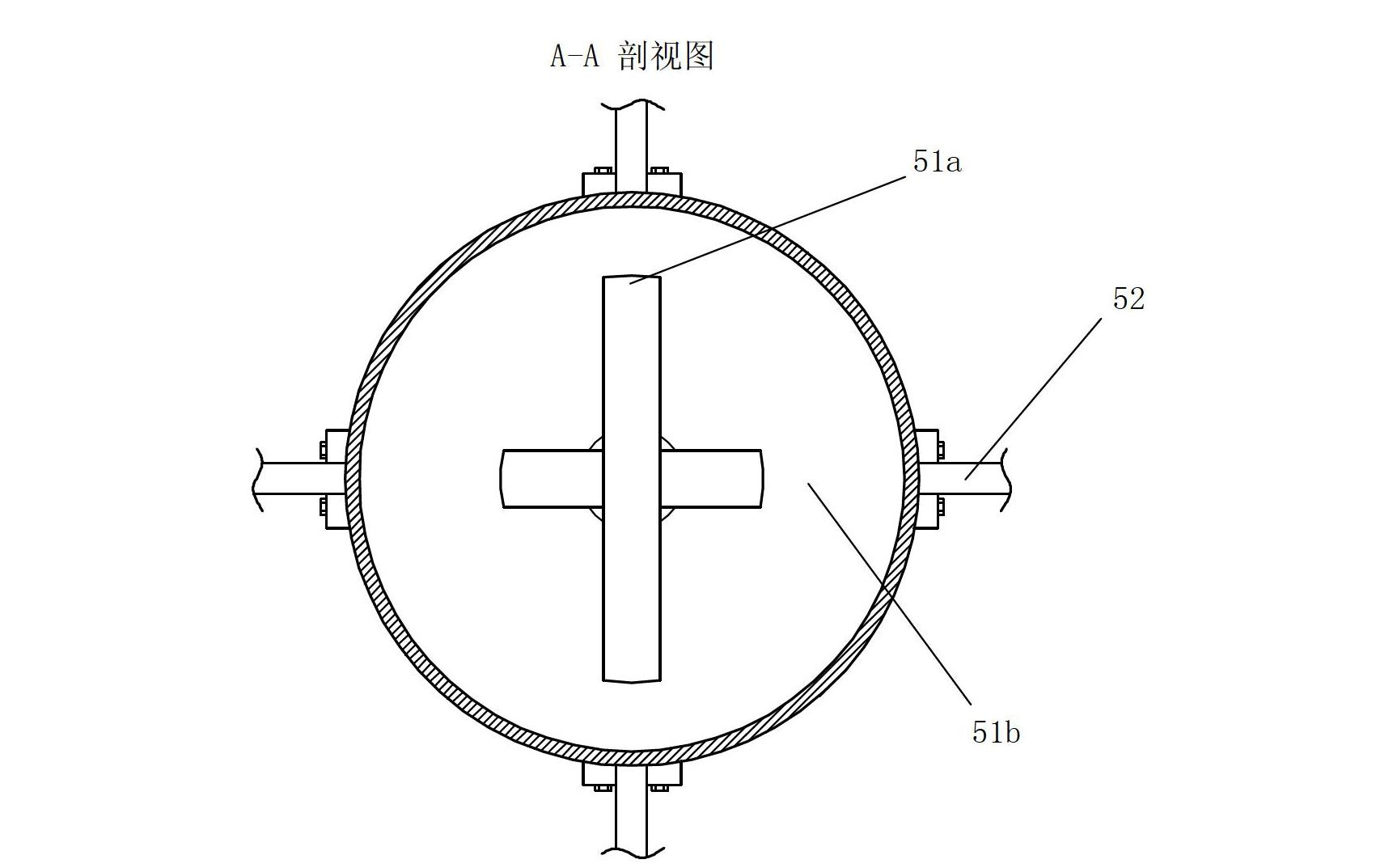

[0041] See Figure 6 , the rest of this embodiment is the same as that of Embodiment 1, the difference is that there are four sleeves 51 . There are two upper casing pipes 51a and two lower casing pipes 51b. The two upper sleeves 51a are arranged horizontally along the front and rear directions, and the two upper sleeves 51a are arranged left and right apart from each other. The two lower sleeves 51b are arranged horizontally along the left and right directions, and the two lower sleeves 51b are arranged front and rear apart from each other.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com