Deashing device and method for waste incineration boiler and biomass boiler

A biomass boiler and waste incineration technology, applied in the boiler field, can solve the problems of high investment cost, poor economy, difficult to remove slagging, etc., and achieve the effects of lower tube wall temperature, good fatigue resistance, and convenient deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

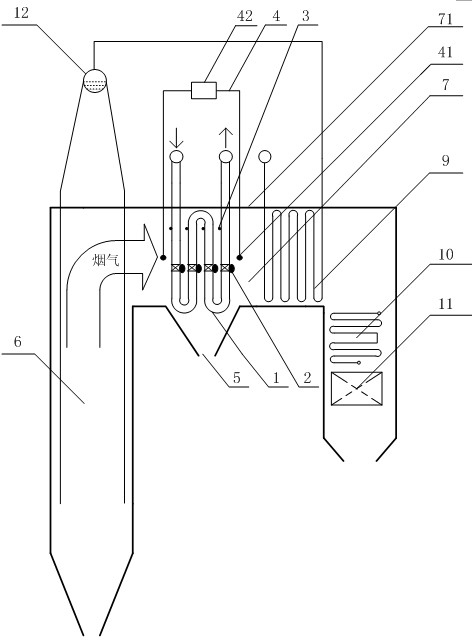

[0034] The convection tube bundle in the horizontal flue exit of a 75t / h waste incineration boiler furnace in a power plant is made of φ51mm×4 steel pipes, arranged in 42 rows horizontally and 13 rows vertically, with a horizontal pitch of 140mm and a vertical pitch of 150mm. The average temperature of the flue gas is 750°C. The device is used to remove ash deposits; considering the size of the horizontal flue at the furnace outlet and the characteristics of the combustion flue gas, the metal hose is made of φ38mm high-temperature resistant pipes, arranged in 4 rows in a staggered manner, with a horizontal intercept of 65mm and a longitudinal intercept of 150mm. The hose is arranged 300mm in front of the first group of convection tube bundles; the push rod is made of φ70mm 06Cr25Ni20 stainless steel tube, and the temperature measuring device is a K-type thermocouple, which is arranged on the windward side of the metal hose tube row and the appropriate position on the push rod su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com