Cross flow wind wheel and air treatment device with same

A technology of air treatment device and cross-flow wind wheel, which is applied to parts of pumping devices for elastic fluids, liquid fuel engines, mechanical equipment, etc., and can solve the problem of not having tiny adsorption and dust removal functions, and heavy loads on motors and fans , the filter is easy to block and other problems, and the dust removal efficiency will not decay, the service life is long, and the structure is simple and reasonable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

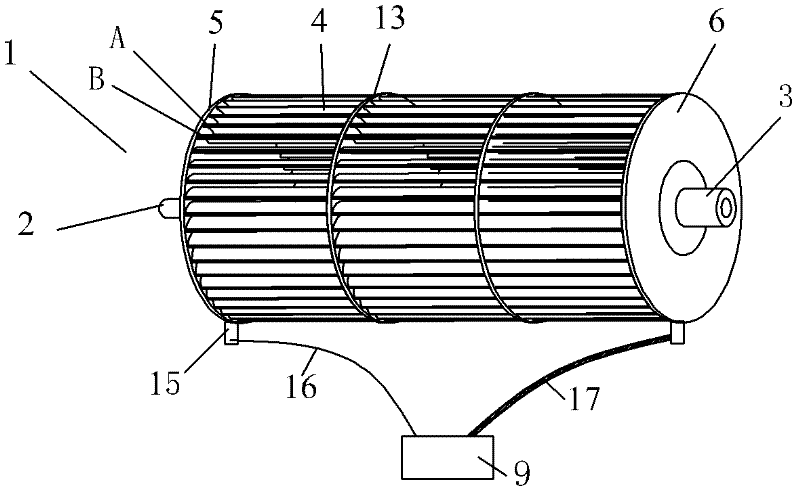

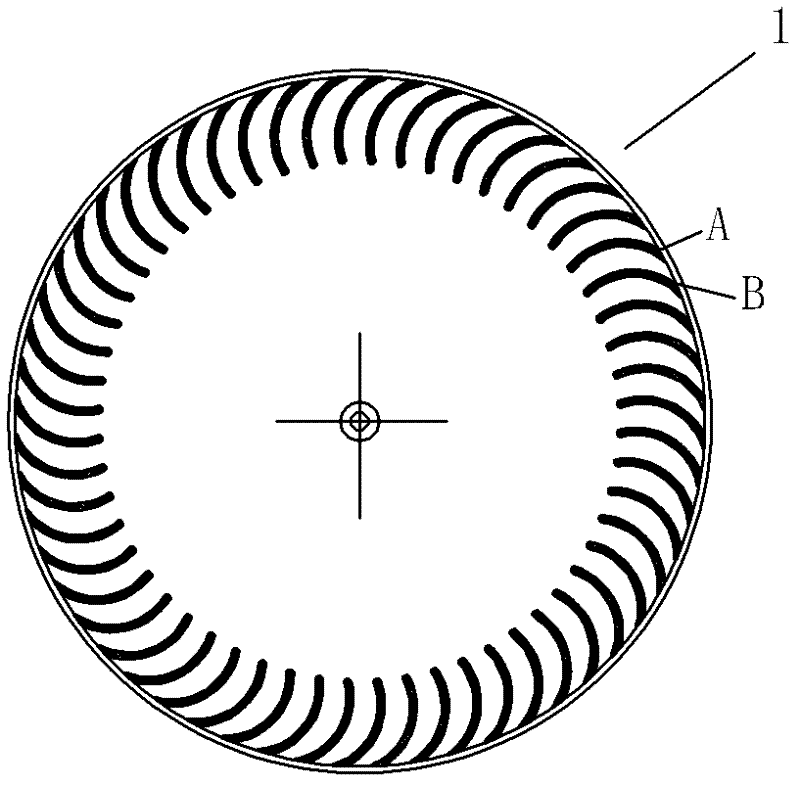

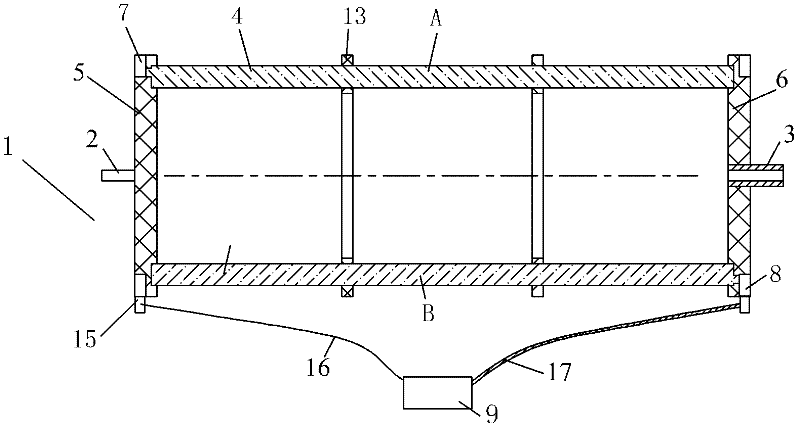

[0045] see Figure 1-Figure 3 , the cross-flow wind wheel 1 includes a shaft 2, a shaft sleeve 3 and blades 4, the blades 4 are arranged in a ring shape at intervals along the circumferential direction, the two ends of the blade 4 are provided with a left end plate 5 and a right end plate 6 for fixing it, the shaft 2 and the The axle sleeve 3 is respectively arranged on the left and right end plates, and the middle part of the blade 4 is also provided with more than one intermediate partition 13 that can strengthen its rigidity. There are two intermediate partitions 13 in this embodiment, and its blade 4 includes several groups that can The conductive first blade A and the second blade B are connected to the high-voltage power supply 9. The potentials of the two groups of blades are different, and they are staggered and non-conductive. A high voltage that can absorb tiny particles in the airflow flowing through the two groups of blades is formed between the two groups of blades. ...

no. 2 example

[0058] see Figure 4 The main difference between this embodiment and the first embodiment is that a second conductive ring 8 is provided on the outer circumference of the right end plate 6 , and a first conductive ring 7 is provided on the inner circumference of the right end plate 6 . Since the first conductive ring 7 and the second conductive ring 8 are arranged on the same right end plate 6 , the first conductive ring 7 and the second conductive ring 8 are separated by an insulating layer. That is to say, in addition to the first conductive ring 7 and the second conductive ring 8, other areas of the right end plate 6, the middle partition 13 and the left end plate 5 are all made of insulating materials, so as to ensure that the first blade A and the second blade A Blades B are insulated from each other.

[0059] For clarity, the high-voltage power supply and connecting wires are not shown in the figure. Other unmentioned parts are the same as the first embodiment and will...

no. 3 example

[0061] see Figure 5 The main difference between this embodiment and the first embodiment is that a second conductive ring 8 is provided on the outer circumference of the left end plate 7 , and a first conductive ring 7 is provided on the inner circumference of the left end plate 5 . Since the first conductive ring 7 and the second conductive ring 8 are disposed on the same left end plate 7 , the first conductive ring 7 and the second conductive ring 8 are separated by an insulating layer. That is to say, in addition to the first conductive ring 7 and the second conductive ring 8, other areas of the left end plate 5, the middle partition 13 and the right end plate 6 are all made of insulating materials to ensure that the first blade A and the second blade A Blades B are insulated from each other.

[0062] For clarity, the high-voltage power supply and connecting wires are not shown in the figure. Other unmentioned parts are the same as the first embodiment and will not be re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com