Pre-cleaning agent used before napping monocrystalline silicon piece and application method

A single crystal silicon wafer and cleaning agent technology, applied in chemical instruments and methods, crystal growth, post-processing details, etc., can solve problems such as hydrogen peroxide is easy to decompose, endanger human body safety, contain phosphorus substances, etc., and achieve configuration and use process Simple, no burning and explosion hazard, no harm to human body and environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

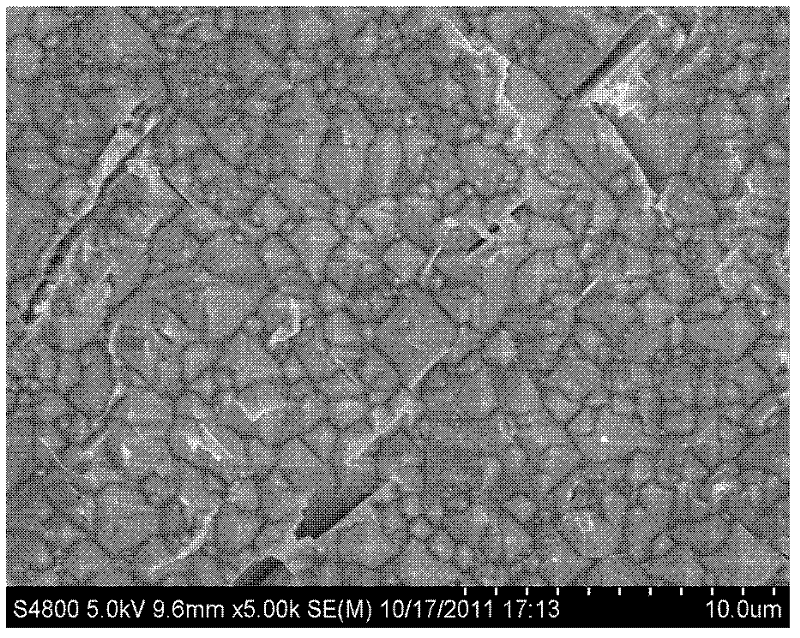

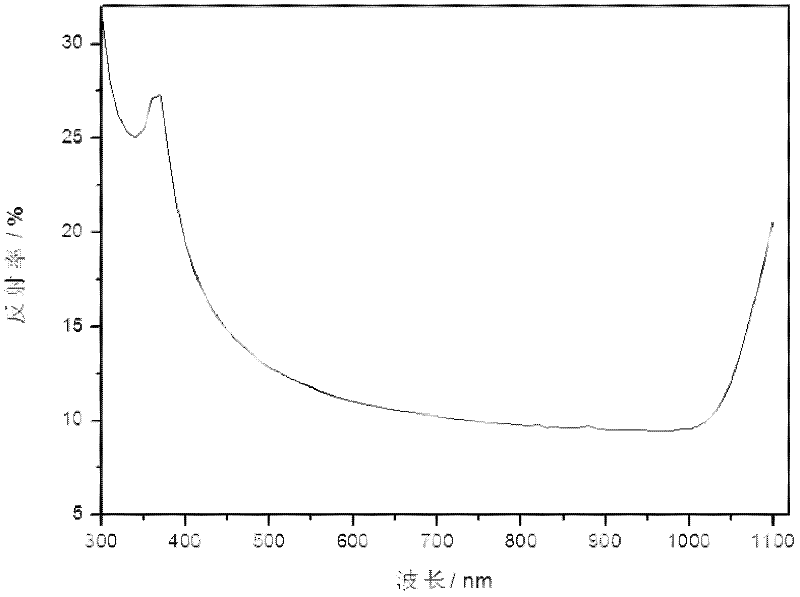

Embodiment 1

[0018] Take the following process steps: 1) prepare alkaline solution: use 40ml deionized water as solvent, dissolve 0.4g sodium hydroxide and 0.3g sodium silicate in deionized water; 2) use 40ml deionized water as solvent, dissolve 0.6 1g sodium citrate, 1g sodium p-toluenesulfonate and 1.6g octylphenol polyoxyethylene ether are dissolved in deionized water; 3) Diethylene glycol dimethyl ether of alkaline solution, 3ml and remaining 17ml deionized water Slowly add to the solution in step 2) to prepare 100ml of pre-cleaning agent; 4) Add 100ml of pre-cleaning agent to the deionized water tank, dilute it according to the volume ratio of 1:50, and then immerse the monocrystalline silicon in the diluted cleaning solution Cleaning is carried out at a temperature of 55°C and a cleaning time of 250s. Texture the cleaned solar silicon wafers according to the common texturing process in the photovoltaic industry to obtain textured silicon wafers, and compare the textured effect.

[0...

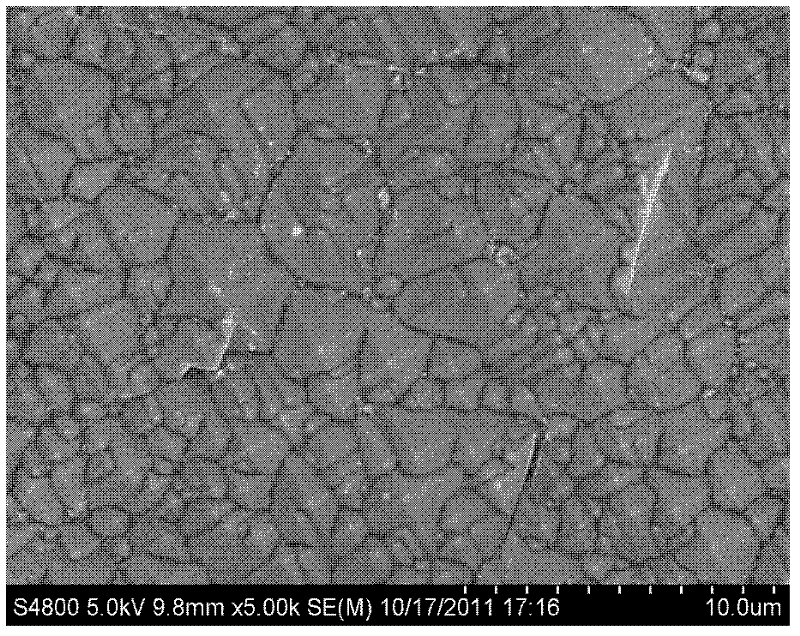

Embodiment 2

[0021] Take the following process steps: 1) prepare alkaline solution: use 40ml deionized water as solvent, dissolve 0.5g sodium hydroxide and 0.4g sodium silicate in deionized water; 2) use 40ml deionized water as solvent, dissolve 0.7 g sodium citrate, 1.1g sodium p-toluenesulfonate, 1g octylphenol polyoxyethylene ether and 0.5g nonylphenol polyoxyethylene ether are dissolved in deionized water; 3) alkaline solution, 4ml diethylene glycol Dimethyl ether and the remaining 16ml of deionized water are slowly added to step 2) in the solution to prepare 100ml of pre-cleaning agent; 4) 100ml of pre-cleaning agent is added in the deionized water tank, diluted at 1:50 according to the volume ratio, and then The single crystal silicon is immersed in the diluted cleaning solution for cleaning, the temperature is 50°C, and the cleaning time is 300s.

Embodiment 3

[0023] Take the following process steps: 1) prepare alkaline solution: use 40ml deionized water as solvent, dissolve 0.4g sodium hydroxide and 0.3g sodium carbonate in deionized water; 2) use 40ml deionized water as solvent, dissolve 0.8g Sodium citrate, 1.2g sodium p-toluenesulfonate and 1.8g octylphenol polyoxyethylene ether are dissolved in deionized water; 3) Diethylene glycol dimethyl ether of alkaline solution, 5ml and remaining 15ml deionized water Slowly add to the solution in step 2) to prepare 100ml of pre-cleaning agent; 4) Add 100ml of pre-cleaning agent to the deionized water tank, dilute it according to the volume ratio of 1:50, and then immerse the monocrystalline silicon in the diluted cleaning solution Cleaning is carried out at a temperature of 60°C and a cleaning time of 180s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com