Tube-shaped flame retardant conveying belt with fabric laminations for coal mine

A technology of conveyor belts and fabrics, applied in the direction of conveyors, transportation and packaging, adhesive types, etc., can solve the problems of large diameter of driving drum, weight of steel wire rope belt, easy corrosion of steel wire rope, etc., and meet the requirements of physical and mechanical properties Requirements, strong pipe forming ability, and easy joint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

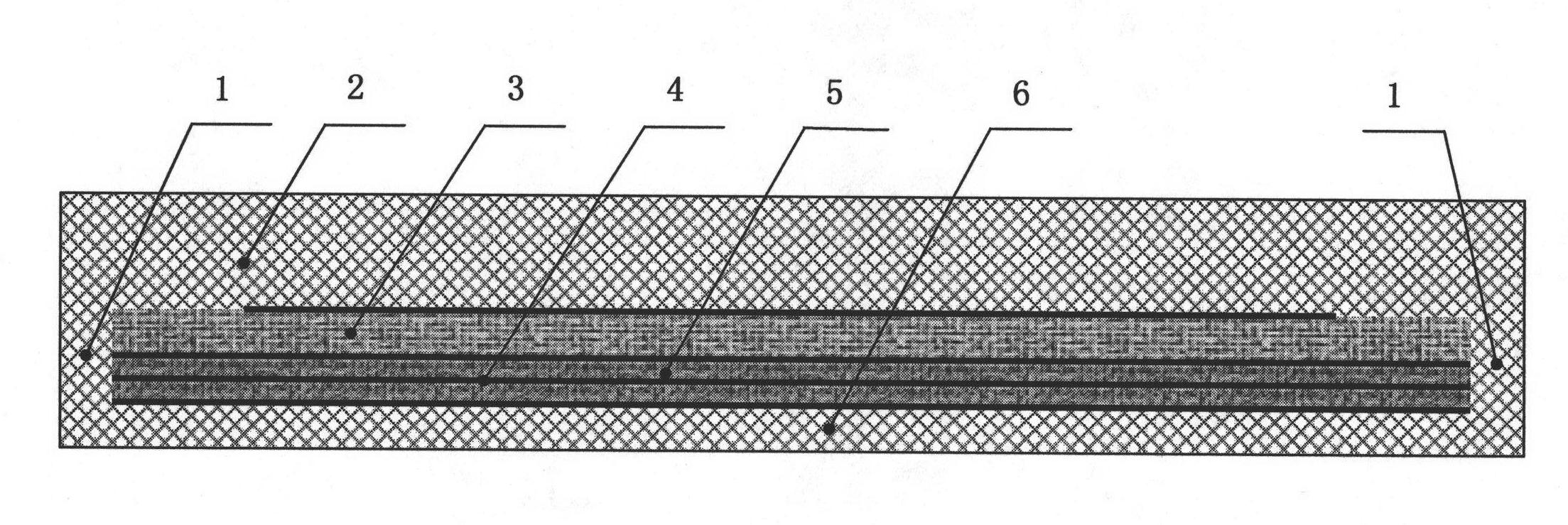

[0061] As shown in the drawings, the present invention includes a side glue 1, an upper flame-retardant covering glue layer 2, a buffer layer 3, a skeleton layer 4, a flame-retardant adhesive glue layer 5, and a lower flame-retardant covering glue layer 6. The skeleton layer 4 shown in the figure has four layers, which are arranged between the upper flame-retardant covering rubber layer 2 and the lower flame-retardant covering rubber layer 6; the buffer layer 3 is close to the upper flame-retardant covering rubber layer 2, and between the skeleton layers , between the skeleton layer and the buffer layer, between the buffer layer and the upper flame-retardant covering rubber layer, and between the skeleton layer and the lower flame-retardant covering rubber layer are bonded into a whole by flame-retardant adhesive glue.

[0062] When the skeleton layer 4 is one layer, a buffer layer 3 is arranged between it and the upper flame-retardant covering rubber layer 2 . When the skelet...

Embodiment 2

[0064] As shown in the drawings, the present invention includes a side glue 1, an upper flame-retardant covering glue layer 2, a buffer layer 3, a skeleton layer 4, a flame-retardant adhesive glue layer 5, and a lower flame-retardant covering glue layer 6. The skeleton layer 4 adopts 4 layers of flame-retardant EP400 canvas, and the two sides are laminated with flame-retardant adhesive The rubber material is 1.5±0.2mm; the thickness of the buffer layer 3 arranged between the skeleton layers 4 is 2.0±0.2mm. Between the skeleton layers, between the skeleton layer and the buffer layer, between the buffer layer and the upper flame-retardant covering rubber layer, between the skeleton layer and the lower flame-retardant covering rubber layer are bonded into a whole by flame-retardant adhesive glue.

[0065] The same formula is used for the flame-retardant adhesive layer and buffer layer, and the ratio by weight is:

[0066] Natural rubber: 75 parts Styrene-butadiene rubber: 25 pa...

Embodiment 3

[0099] Structural form is with embodiment 2. Skeleton layer 4 is made of 4 layers of flame-retardant EP250 canvas, the adhesive layer glue on both sides is 1.2±0.1mm, and the thickness of the buffer layer is 2.0±0.2mm.

[0100] The same formula is used for the flame-retardant adhesive layer and buffer layer, and the ratio by weight is:

[0101] 60 parts of natural rubber, styrene-butadiene rubber: 40 parts,

[0102] Zinc Oxide: 5 parts, Magnesium Oxide: 2 parts, Stearic Acid: 2 parts,

[0103] Accelerator CZ: 1.8 parts, Accelerator DM: 1 part,

[0104] Flame retardant tackifying resin: 8 parts, decabromodiphenyl ether: 12 parts,

[0105] 70 ° chlorinated paraffin: 25 parts, complex antimony synergistic flame retardant: 10 parts,

[0106] Zinc borate: 13 parts, superfine aluminum hydroxide: 25 parts,

[0107] New modified borate coupling dispersant: 1.5 parts,

[0108] Super wear-resistant carbon black in the new process: 35 parts, superfine silicon-aluminum carbon black:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com