Chemical packaging barrel

A packaging barrel and chemical technology, applied in the field of chemical packaging containers, can solve the problems of staff injury, easy deformation, easy deterioration, etc., and achieve the effects of avoiding volatilization or leakage, maintaining pressure balance, and protecting product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

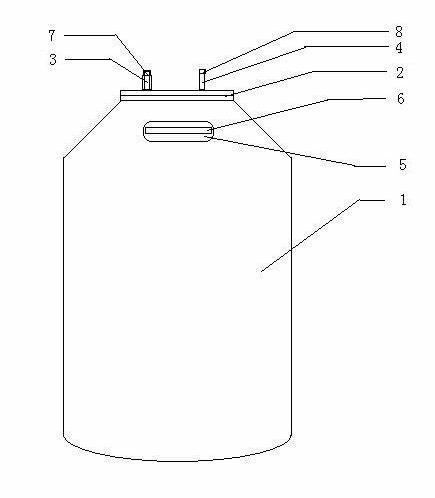

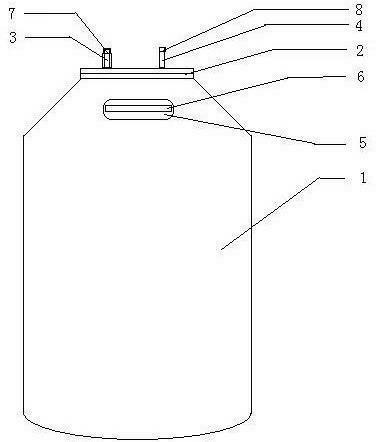

[0013] see figure 1 , the chemical packaging barrel of this embodiment mainly comprises a barrel body 1 made of stainless steel, a barrel lid 2 positioned above the barrel body 1, and a recessed platform 5 and a grip portion 6 arranged above the barrel body 1 on both sides of the barrel lid 2. The lid 2 is formed with a first joint 3 for the liquid to enter the barrel body 1, and a second joint 4 arranged on the lid 2 for connecting the intake pipe or the exhaust pipe, and for closing the first joint 3 respectively and the sealing caps 7 and 8 of the second joint 4, the volume of the packaging bucket is 4L.

Embodiment 2

[0015] see figure 1 , the chemical packaging barrel of this embodiment mainly comprises a barrel body 1 made of stainless steel, a barrel lid 2 positioned above the barrel body 1, and a recessed platform 5 and a grip portion 6 arranged above the barrel body 1 on both sides of the barrel lid 2. The lid 2 is formed with a first joint 3 for the liquid to enter the barrel body 1, and a second joint 4 arranged on the lid 2 for connecting the intake pipe or the exhaust pipe, and for closing the first joint 3 respectively and the sealing caps 7 and 8 of the second joint 4, the volume of the packaging bucket is 9L.

Embodiment 3

[0017] see figure 1 , the chemical packaging barrel of this embodiment mainly comprises a barrel body 1 made of stainless steel, a barrel lid 2 positioned above the barrel body 1, and a recessed platform 5 and a grip portion 6 arranged above the barrel body 1 on both sides of the barrel lid 2. The lid 2 is formed with a first joint 3 for the liquid to enter the barrel body 1, and a second joint 4 arranged on the lid 2 for connecting the intake pipe or the exhaust pipe, and for closing the first joint 3 respectively and the sealing caps 7 and 8 of the second joint 4, the volume of the packaging bucket is 7L.

[0018] When using the packaging barrel of this embodiment to fill liquid products, it is only necessary to directly connect the feed pipe to the first joint 3, and connect the exhaust pipe to the second joint 4. Generally, the air is exhausted while feeding, which can maintain the pressure balance inside the barrel and discharge The air pipe can be connected to the exhau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com