Continuous forging die

A mold and forging technology, applied in the field of molds, can solve the problems of low production efficiency, high cost, low production efficiency, etc., and achieve the effect of high production efficiency and mass production, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following descriptions are only preferred embodiments embodying the principles of the present invention, and do not therefore limit the protection scope of the present invention.

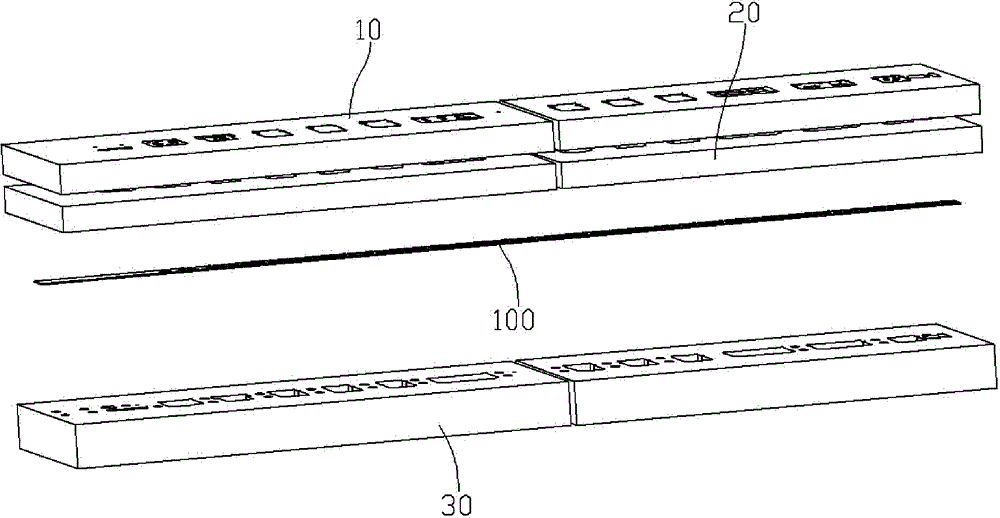

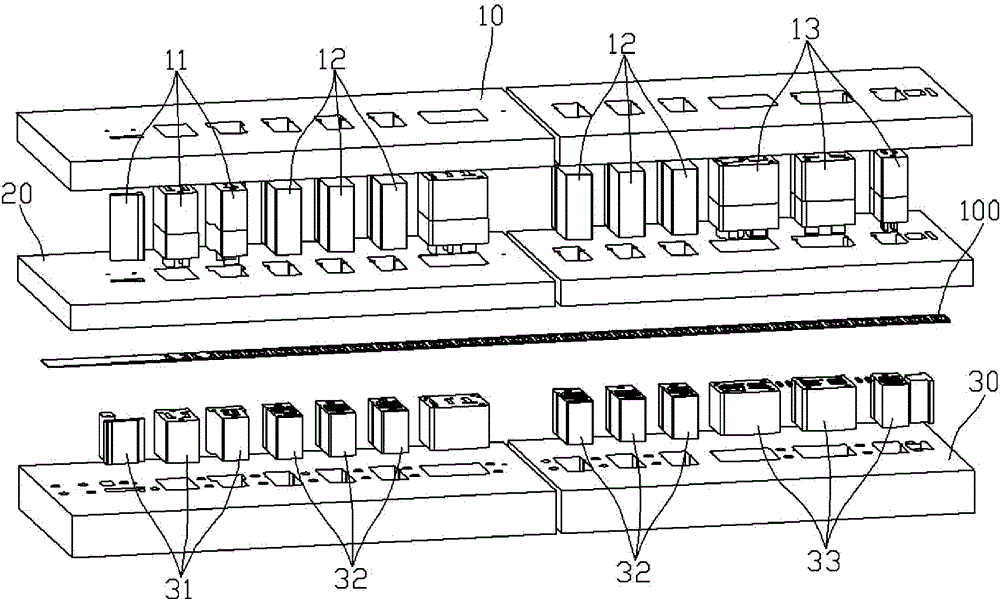

[0016] See figure 1 with figure 2 Shown: the continuous forging die of the present invention comprises the patrix 10 that is divided into two sections (certainly also can be three sections or more than three sections), patrix stripping plate 20, and lower mold 30, wherein, on the body of patrix 10 There are a plurality of stamping punches 11, upper die forging forming blocks 12, and bending blanking punches 13 arranged continuously, and the body of the lower die 30 has a corresponding plurality of stamping lower dies 31, lower die forging forming blocks 32, And bending blanking lower die 33.

[0017] Stamping punch 11, upper die forging forming block 12, and bending blanking punch 13 are inserts that are movably connected with the body of upper die 10; stamping lower die 31, lower die ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com