A composite structure artificial blood vessel and its dynamic preparation method

A technology of artificial blood vessels and composite structures, which is applied in the fields of blood vessels, human tubular structure devices, medical science, etc. Controllable layer quantity and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The material of the tube blank adopts 50D / 12f viscose glossy yarn; the warp and weft yarn structure is three-ply joint knitting; Figure 5 Shown is woven from ground warp 6, twisted warp 7, and weft yarn 8). Fabric parameters: warp density * weft density (threads / 10cm) is 400*100, folding diameter (mm) is 10, and total warp number (roots) is 40.

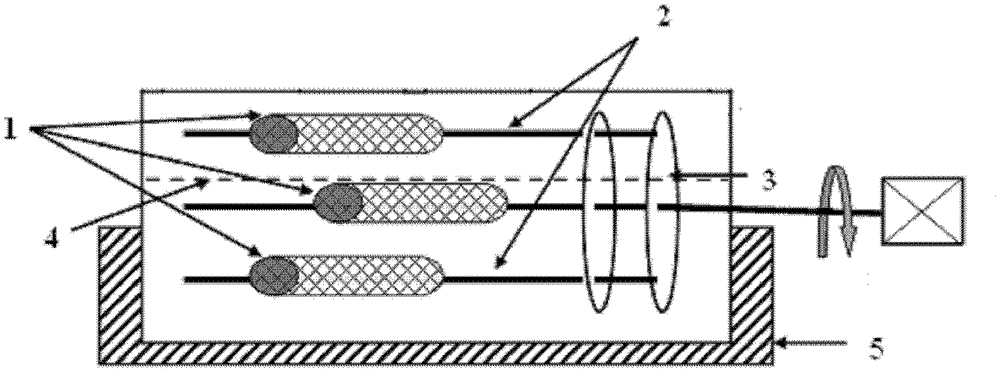

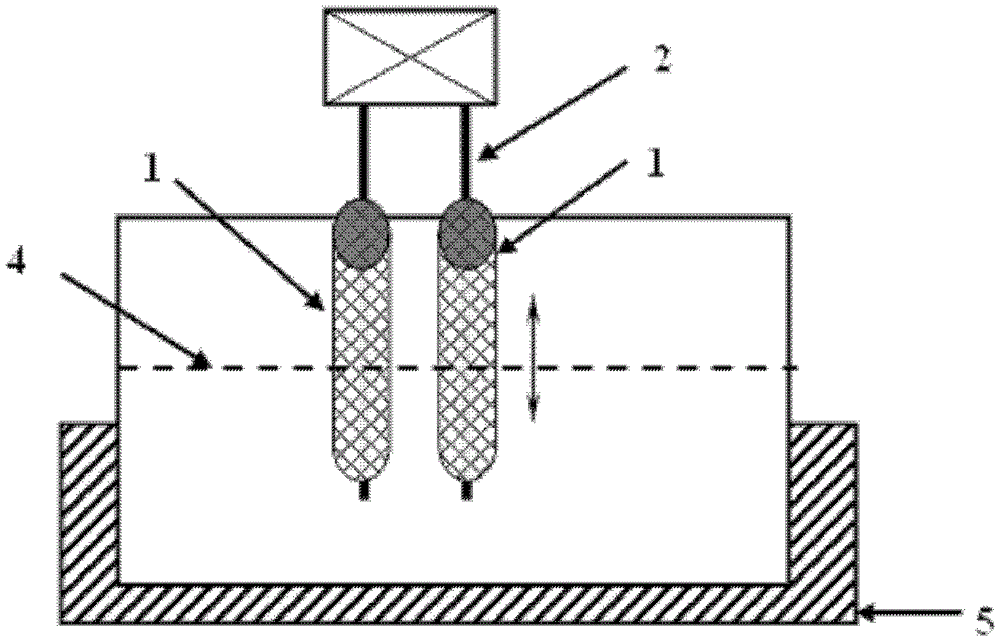

[0043] Weaving organization chart see Figure 4 . The cellulose fermented by Acetobacter xylinum is selected to coat the tube blank. in the bioreactor ( figure 1 with 2 ) for 1-7 days to ferment and culture, and finally prepare bacterial cellulose-coated small-diameter artificial blood vessels.

[0044] Fermentation culture process:

[0045] (1) Strain cultivation: insert Acetobacter xylinum into 300mL liquid medium (per 1L of water, 20g of mannitol, 3g of peptone, 5g of yeast extract, pH 3.0, sterilized at 121°C for 20min; or 200g of glucose , yeast extract 5g, tryptone 5g, citric acid 115g, Na 2 HPO 4 2.7g, 1L of wa...

Embodiment 2

[0048] The material of the tube blank is 50D / 12f viscose glossy yarn; the yarn structure is three-ply joint knitting; Fabric parameters: warp density * weft density (pieces / 5cm) is 35*55, cylinder diameter (mm) is 6.

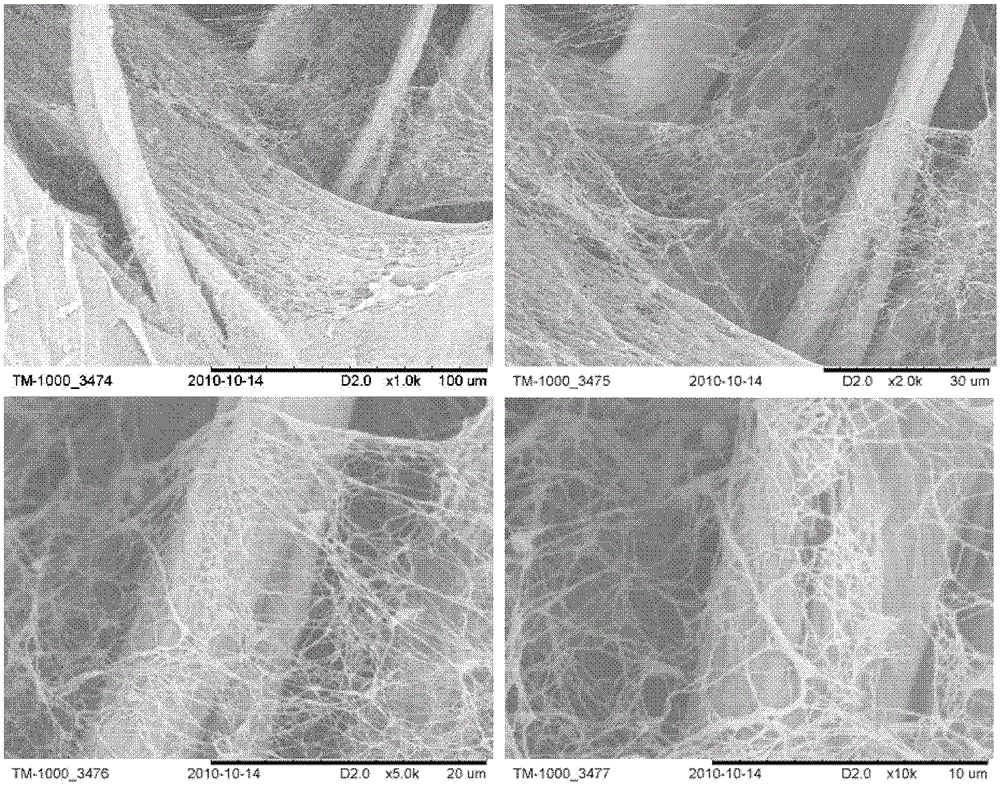

[0049] Weaving organization chart see Image 6 . Cellulose fermented by Gluconobacteroxydans is selected to coat the tube blank. in the bioreactor ( figure 1 with 2 ) for 1-7 days to ferment and culture, and finally prepare bacterial cellulose-coated small-diameter artificial blood vessels. Electron micrographs of artificial vascular materials coated with nanocellulose and image 3 The results are similar.

[0050] Fermentation culture process:

[0051] (1) Strain cultivation: Insert Gluconobacteroxydans into 300mL liquid medium (per 1L of water, mannitol 20g, peptone 3g, yeast extract 5g, pH 3.0, sterilized at 121°C for 20min; or glucose 200g , yeast extract 5g, tryptone 5g, citric acid 115g, Na 2 HPO 4 2.7g, 1L of water, pH 7.5, sterilized at 121°C f...

Embodiment 3

[0054] The yarn of the tube blank is made of 50D / 12f viscose glossy yarn; the basic structure is a rope-knitted tubular structure. Fabric parameters: the number of bobbins is 32, and the diameter (mm) of the core tube is 6.

[0055] Cellulose fermented by kombucha is selected to coat the tube stock. in the bioreactor ( figure 1 with 2 ) for 1-7 days to ferment and culture, and finally prepare bacterial cellulose-coated small-diameter artificial blood vessels. Electron micrographs of artificial vascular materials coated with nanocellulose and image 3 The results are similar.

[0056] Fermentation culture process:

[0057] (1) Strain cultivation: put black tea fungus (kombucha) into 300mL liquid seed culture medium according to the inoculation amount of 5 discs with a diameter of 0.5cm containing bacteria BC membrane (every 1L of water, green tea 5g, glucose 10, peptone 3g , Yeast extract 5g, pH3.0, pasteurized for 30min; per 1L of water, glucose 100g, peptone 3g, yeast e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com