Production method for non-browned processed cheese stored at room temperature

A technology for processing cheese and storing at room temperature, applied in cheese substitutes, dairy products, applications, etc., can solve problems such as browning, and achieve the effect of eliminating pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

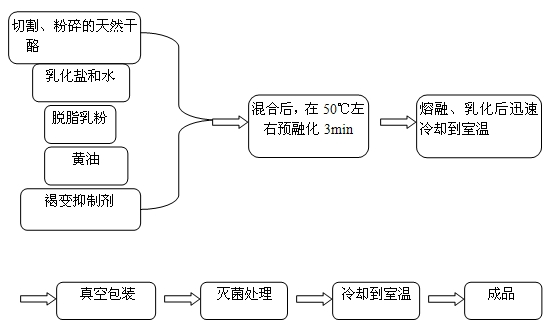

Method used

Image

Examples

Embodiment Construction

[0008] The methods described in the following examples are conventional methods unless otherwise specified.

[0009] The percentages described in the following methods are all mass percentages unless otherwise specified.

[0010] The principle of the method of the present invention: select natural cheese with suitable maturity and appropriate ratio (to ensure that processed cheese has better texture and flavor), select Cheddar cheese (maturation period of two months) and Gouda cheese (maturation period of 8 months) month) ratio of 1.5:1. Add 3.2% skimmed milk powder to increase the dry matter content while ensuring the texture of the processed cheese without residue, and add 7.3% butter (desalted) to increase the fat content. The added emulsifying salts are sodium pyrophosphate and trisodium citrate, adding 2% in a ratio of 1:1. The moisture content in processed cheese affects its hardness, viscosity and browning degree. The moisture content added in the present invention is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com