Sugar-free sea-buckthorn cushions and manufacture process thereof

A technology of crispy candy and seabuckthorn, which is applied in the field of hard crispy candy and its production process, can solve the problems of not being able to show the maximum plasticity, hard crispy candy is hard, and cannot be formed, so as to be beneficial to the body and senses. No change, good quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] A sugar-free seabuckthorn crispy candy, the main component ratio (weight) is as follows: 63.5 parts of maltitol, 28.5 parts of peanut butter, 0.2 parts of sea buckthorn juice, 7.8 parts of wheat flour, and 0.02 parts of vanillin.

Embodiment 2

[0013] A sugar-free seabuckthorn crispy candy, the main component ratio (weight) is as follows: 73.5 parts of maltitol, 18.5 parts of peanut butter, 0.2 parts of sea buckthorn juice, 7.8 parts of wheat flour, and 0.02 parts of vanillin.

Embodiment 3

[0015] A sugar-free seabuckthorn crispy candy, the main component ratio (weight) is as follows: 68.5 parts of maltitol, 23.5 parts of peanut butter, 0.2 parts of sea buckthorn juice, 7.8 parts of wheat flour, and 0.02 parts of vanillin.

[0016] The production process of the sugar-free seabuckthorn crispy candies described in the above-mentioned Examples 1-3 is operated according to the following steps: first, measure each component, and boil the maltitol at a temperature of 205±1°C, and heat it on an open flame Under the conditions, the cooking time is 25-30 minutes, then cooled to 80°C, divided into pieces, whitened, wrapped in mixed components except maltitol, and finally coated and shaped.

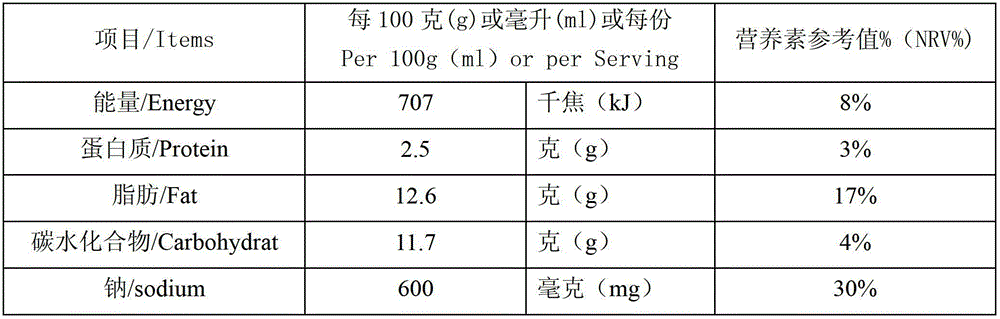

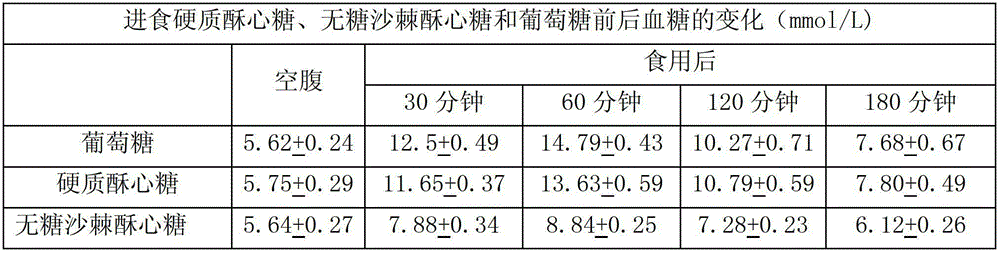

[0017] Attachment: Blood sugar experiment of sugar-free seabuckthorn crispy sugar

[0018] 1. Research object

[0019] Thirty-one patients with non-insulin-dependent diabetes mellitus were diagnosed according to WHO (1985) criteria. There were 13 males and 18 females, with an average...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com