Sugar-free lobster cushions and process for making same

A technology of crispy candy and red shrimp, which is applied in the field of hard crispy candy and its production process. The effect of simple taste and process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

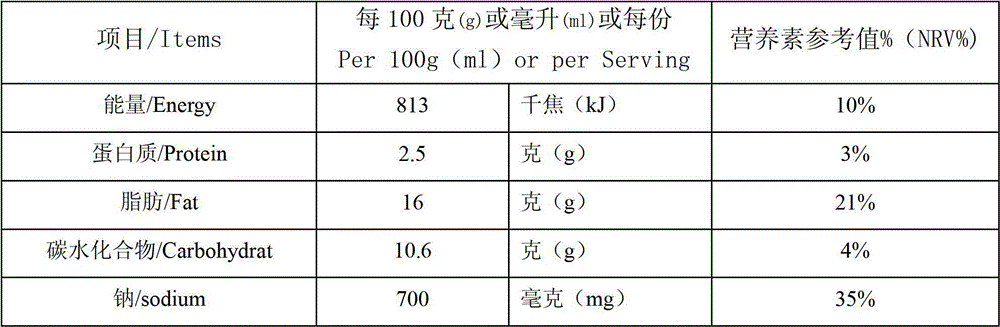

[0011] A sugar-free red shrimp crispy candy, the main component ratio (weight) is as follows: 60 parts of maltitol, 35 parts of peanut butter, 4 parts of wheat flour, 1 part of water, and 0.02 part of vanillin.

Embodiment 2

[0013] A sugar-free red shrimp crispy candy, the main component ratio (weight) is as follows: 70 parts of maltitol, 25 parts of peanut butter, 4 parts of wheat flour, 1 part of water, and 0.02 parts of vanillin.

Embodiment 3

[0015] A sugar-free red shrimp crispy candy, the main component ratio (weight) is as follows: 65 parts of maltitol, 30 parts of peanut butter, 4 parts of wheat flour, 1 part of water, and 0.02 part of vanillin.

[0016] The production process of the sugar-free red shrimp crispy candy described in the above-mentioned Examples 1-3 is operated according to the following steps: firstly, each component is measured, and the maltitol is boiled at a temperature of 205±1°C. The cooking time under heating conditions is 25-30 minutes, then cooled to 80°C, divided into pieces, whitened, wrapped in mixed components except maltitol, and finally coated and shaped.

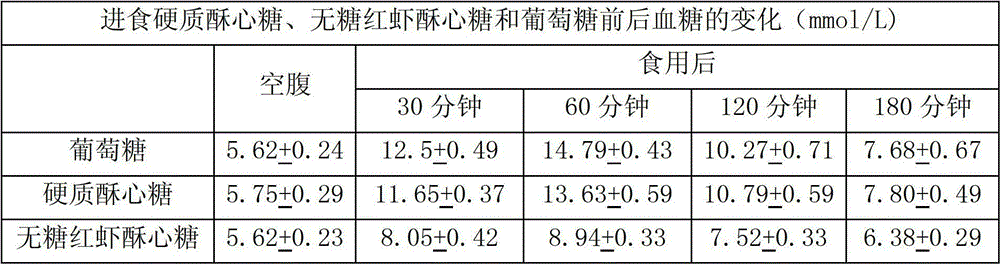

[0017] Attachment: Sugar-free red shrimp crispy sugar blood sugar experiment

[0018] 1. Research object

[0019] Thirty-one patients with non-insulin-dependent diabetes mellitus were diagnosed according to WHO (1985) criteria. There were 13 males and 18 females, with an average age of 57 years (29-75 years), an average disease...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com