Catalytic reactor including a catalytic cellular structure and at least one structural element

A technology of catalytic reactors and structural components, applied in the direction of gas-to-gas reactions under catalytically active bodies, chemical instruments and methods, chemical/physical/physicochemical processes, etc., can solve the problems of lack of conductive heat transfer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

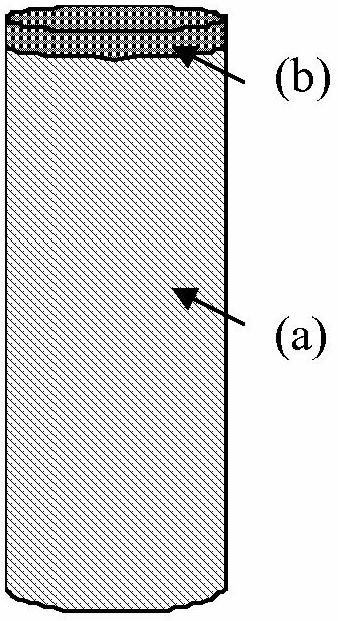

[0044] figure 1 show:

[0045] - a / some ceramic and / or metallic porous structures (a) having a controlled catalytic microstructure, and

[0046] - Static mixers (b), which are in particular metallic.

[0047]In this reactor, the catalytic bed is constructed entirely of ceramic foam in order to benefit from the concentration of catalytic activity and optimal heat transfer along the entire tube. A static mixer at the inlet prevents possible preferential flow at the walls. The static mixer is in contact with the inner wall of the reactor. Foams can also have metallic properties.

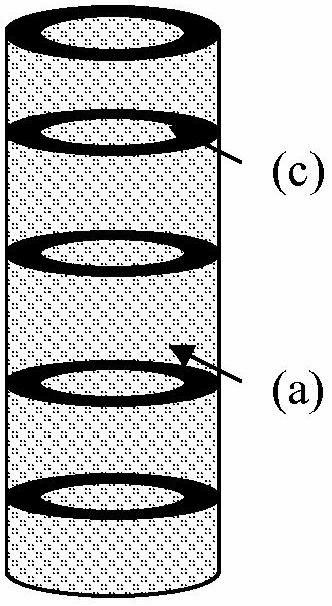

[0048] figure 2 show:

[0049] - ceramic and / or metallic porous structures (a) with a controlled catalytic microstructure (these structures are for example stacked blocks of catalytic ceramic foam), and

[0050] - preferably metallic or ceramic non-catalytic structural elements in the form of rings (c) between porous structures. For structural elements of a ceramic nature in the context, non-o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com