MEMS (micro-electro-mechanical system) acoustic sensor based on graphene

An acoustic sensor and graphene technology, applied in the field of micro-sensors, can solve the problems of insufficient sensitivity and self-noise, and achieve the effects of high sensitivity, strong flexibility, and good structural consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further explained below in conjunction with the drawings:

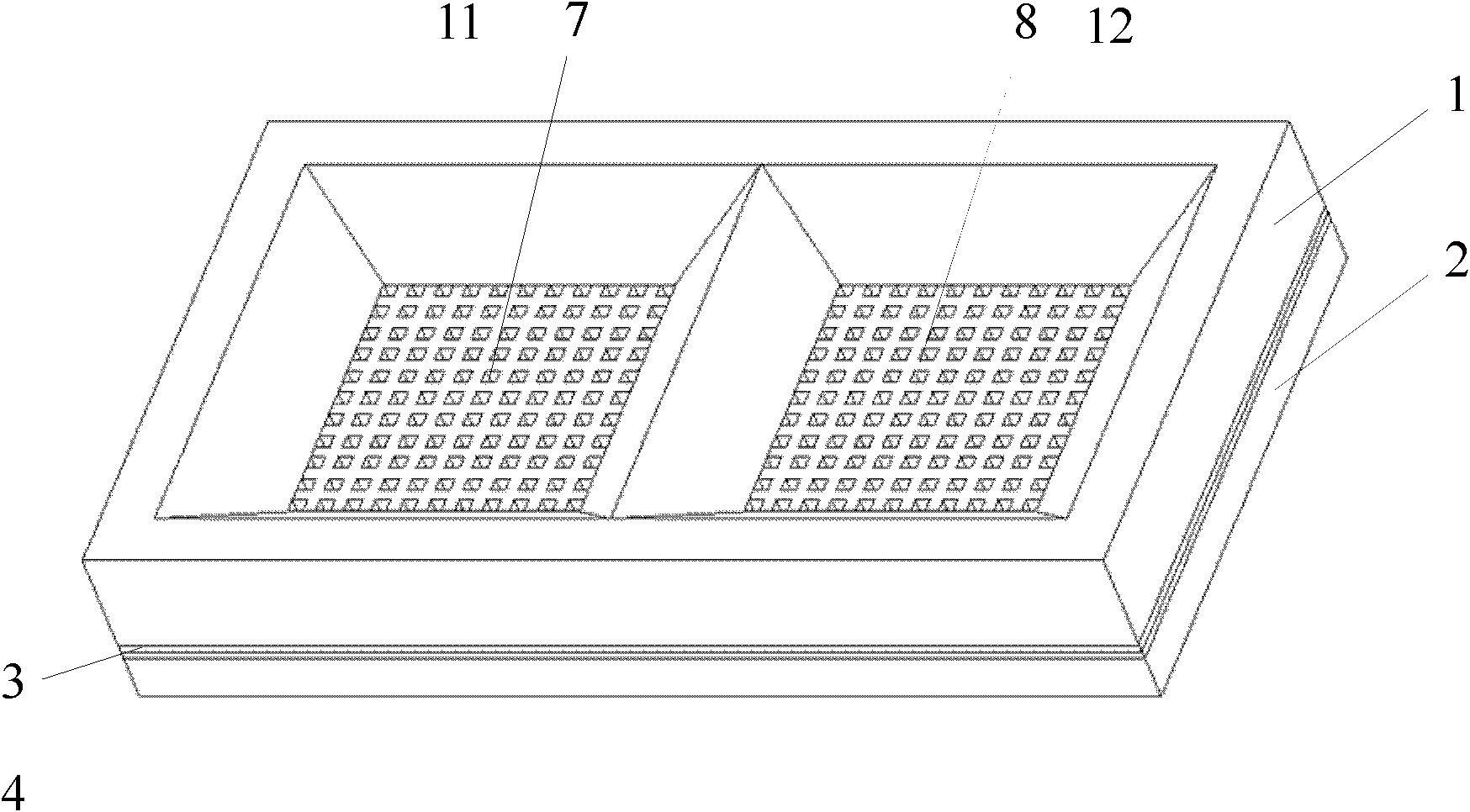

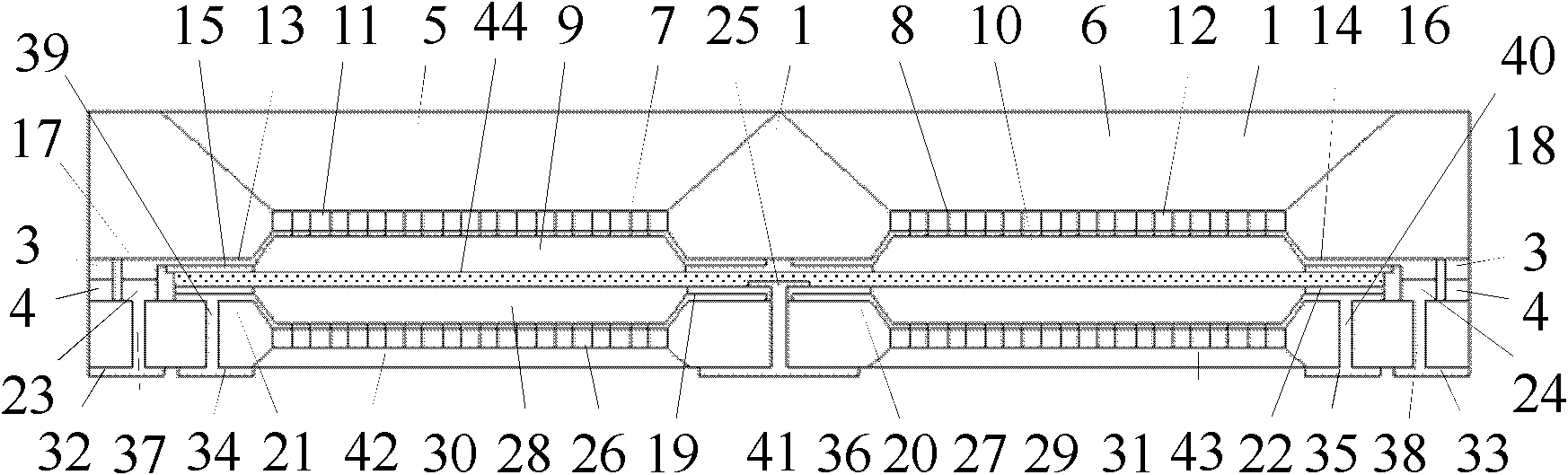

[0023] figure 1 It is a three-dimensional view of the overall structure. The upper metal layer 3 is made on the bottom surface of the upper structure layer 1, and the lower metal layer 4 is made on the surface of the lower structure layer 2. The upper structure layer 1 passes through the bonds of the upper metal layer 3 and the lower metal layer 4. The joint is firmly connected to the lower structure layer 2.

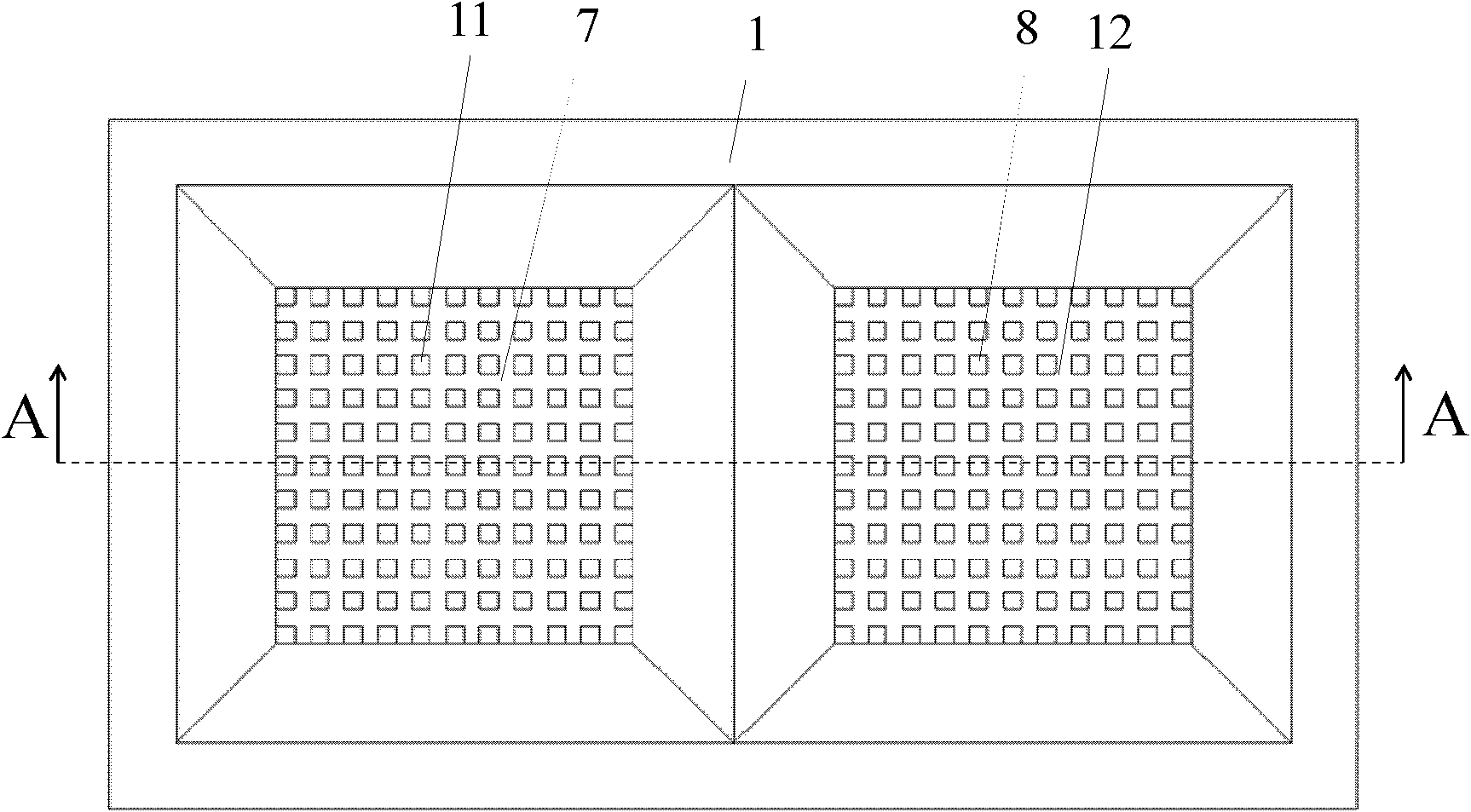

[0024] figure 2 It is a plan view of the overall structure. The upper structure layer 1 has sound collecting cavities 5 and 6, and the bottom of the sound collecting cavities 5 and 6 are provided with through-hole plates 7, 8, and the through-hole plates 7, 8 are evenly distributed with sound pickup holes 11 , 12.

[0025] The sound collecting cavities 5 and 6 are in an inverted quadrangular pyramid structure and are made by a silicon wet process. The volume of the sound collecti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electron mobility | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com