Layer-by-layer electrostatic self-assembling method based on dopamine-modified polyelectrolyte and application

An electrostatic self-assembly and polyelectrolyte technology, which is applied in the field of surface modification of biomedical materials, can solve the problems of simplicity and universality discount of layer-by-layer assembly technology, and achieves elimination of substrate treatment, widening of application fields, and easy operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

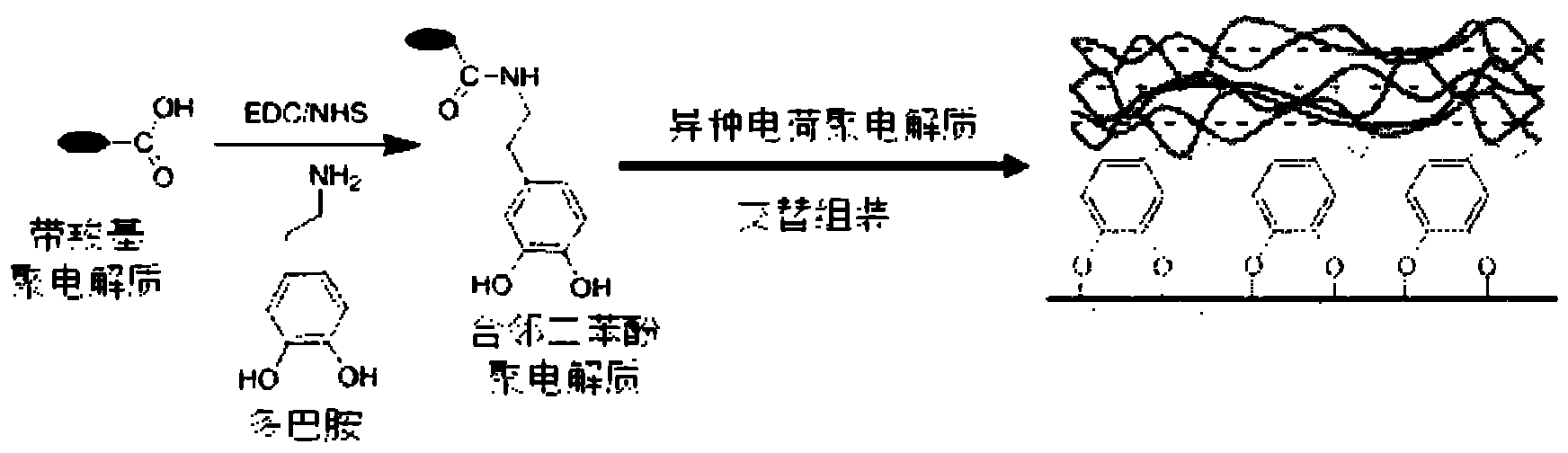

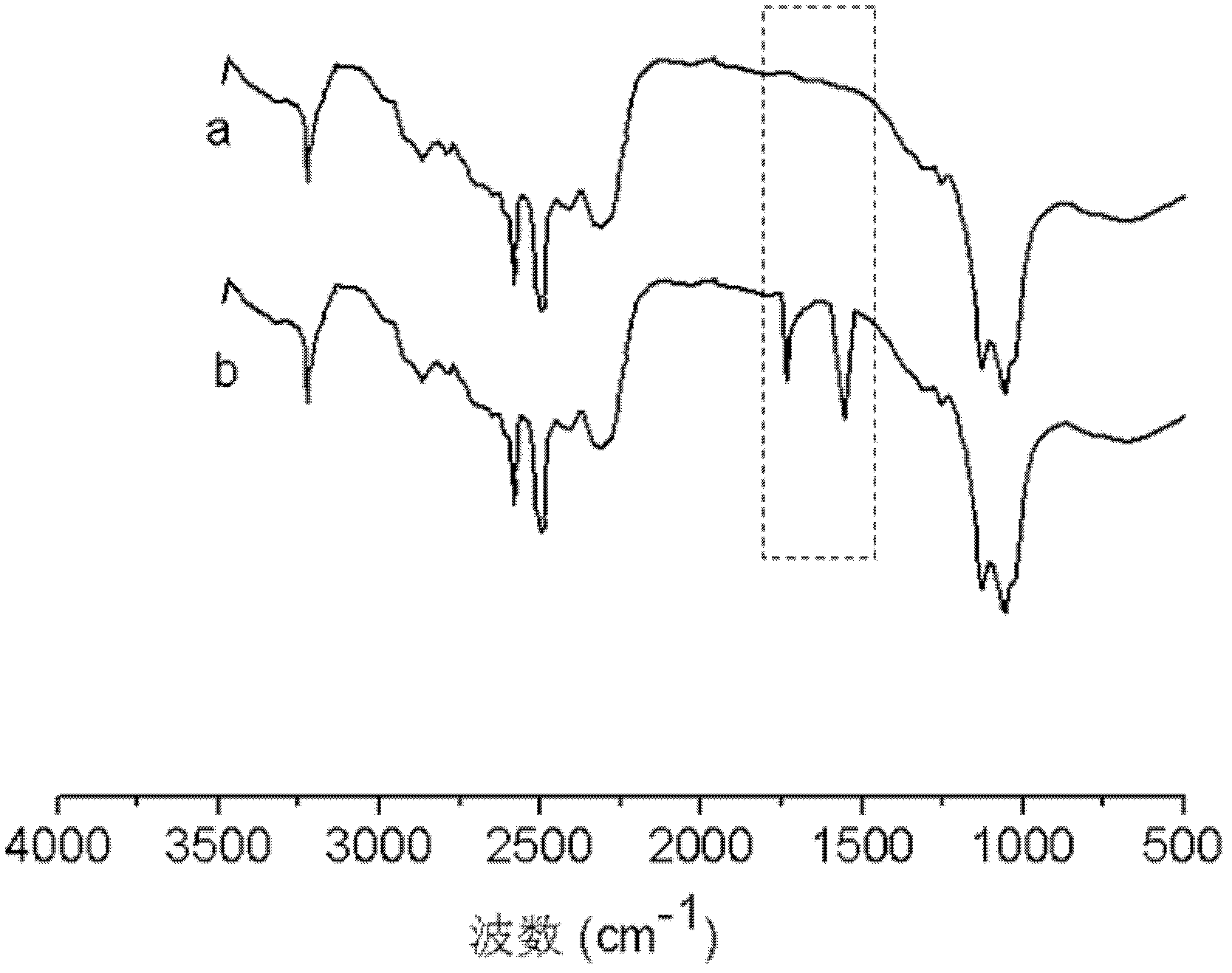

[0021] This example is a layer-by-layer electrostatic assembly of multilayer films based on dopamine-modified polyelectrolytes on the surface of titanium alloys, without pretreatment on the surface of the material, that is, the surface of the material does not need to be pre-charged.

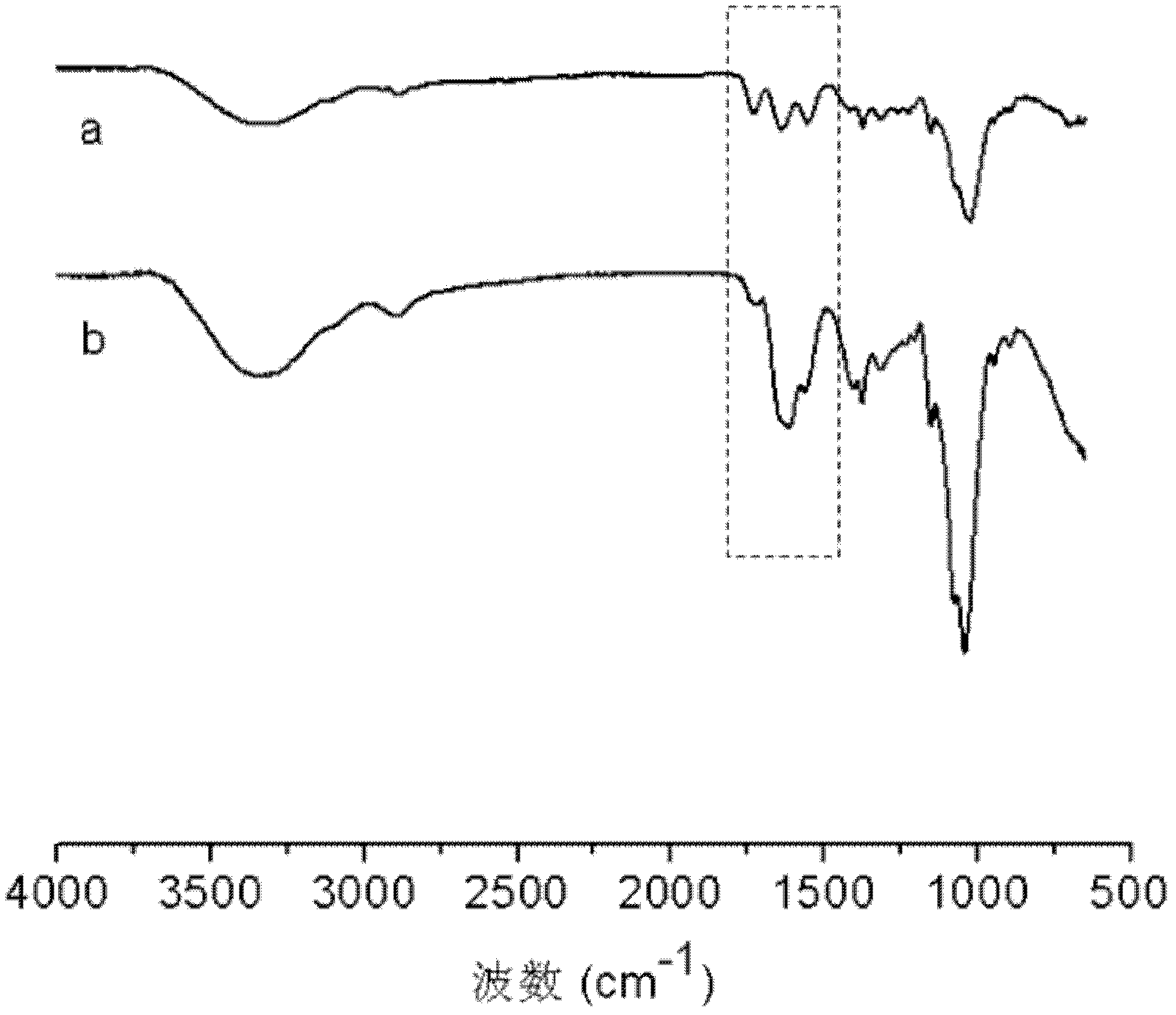

[0022] First, dopamine-modified hyaluronic acid was synthesized, and 0.1 g of hyaluronic acid was dissolved in 10 mL of PBS solution with pH=5.5. Add 40 mg of carbodiimide (EDC) into the solution, react for 15 minutes, add 60 mg of N-hydroxysuccinimide (NHS) and 50 mg of dopamine and react in the dark for 12 hours. During the reaction, use 1M HCl or 1M NaOH to maintain the solution pH=5.5, The solution was dialyzed and freeze-dried. Its electrostatic assembly process includes the following steps, and the material is titanium alloy:

[0023] 1) Dissolving dopamine-modified hyaluronic acid in NaCl aqueous solution with pH=5, and preparing a solution with a concentration of 1 mg / mL;

[0024] 2) d...

Embodiment 2

[0034] This example is a layer-by-layer electrostatic assembly of multilayer films based on dopamine-modified polyelectrolytes on the surface of hydroxyapatite, which does not require pretreatment on the surface of the material, that is, the surface of the material does not need to be charged in advance.

[0035] First, dopamine-modified sodium alginate was synthesized by dissolving 0.1 g of sodium alginate in 10 mL of PBS solution with pH=5.5. Add 40 mg of EDC to the solution, react for 15 minutes, add 60 mg of NHS and 50 mg of dopamine and react in the dark for 20 hours. During the reaction, use 1M HCl or 1M NaOH to maintain the pH of the solution at 5.5, dialyze the solution and freeze-dry.

[0036] Its electrostatic assembly process includes the following steps, and the material is hydroxyapatite:

[0037] 1) Dissolving dopamine-modified sodium alginate in NaCl aqueous solution at pH=5, and preparing a solution with a concentration of 1 mg / mL;

[0038] 2) dissolving chito...

Embodiment 3

[0048] This example is a layer-by-layer electrostatic assembly of multilayer films based on dopamine-modified polyelectrolytes on the surface of polytetrafluoroethylene, without pretreatment on the surface of the material, that is, the surface of the material does not need to be charged in advance.

[0049]Firstly, dopamine-modified gelatin was synthesized, and 0.1 g of gelatin was dissolved in 10 mL of PBS solution with pH=5.5. Add 40 mg of EDC to the solution, react for 15 minutes, add 60 mg of NHS and 50 mg of dopamine and react in the dark for 24 hours. During the reaction, use 1M HCl or 1M NaOH to maintain the pH of the solution at 5.5, dialyze the solution and freeze-dry.

[0050] Its electrostatic assembly process includes the following steps, and the material is polytetrafluoroethylene:

[0051] 1) Dissolving dopamine-modified gelatin in NaCl aqueous solution with pH=5, and preparing a solution with a concentration of 1 mg / mL;

[0052] 2) dissolving chitosan in an aqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com