Process and system for purifying and refining coal-bed gas

A refining system and technology for coalbed methane, applied in liquefaction, gas fuel, petroleum industry, etc., can solve the problems of expensive purification equipment, increase operating cost, unfavorable environmental protection, etc., achieve low equipment investment and operating cost, reduce operating cost, The effect of broad market application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

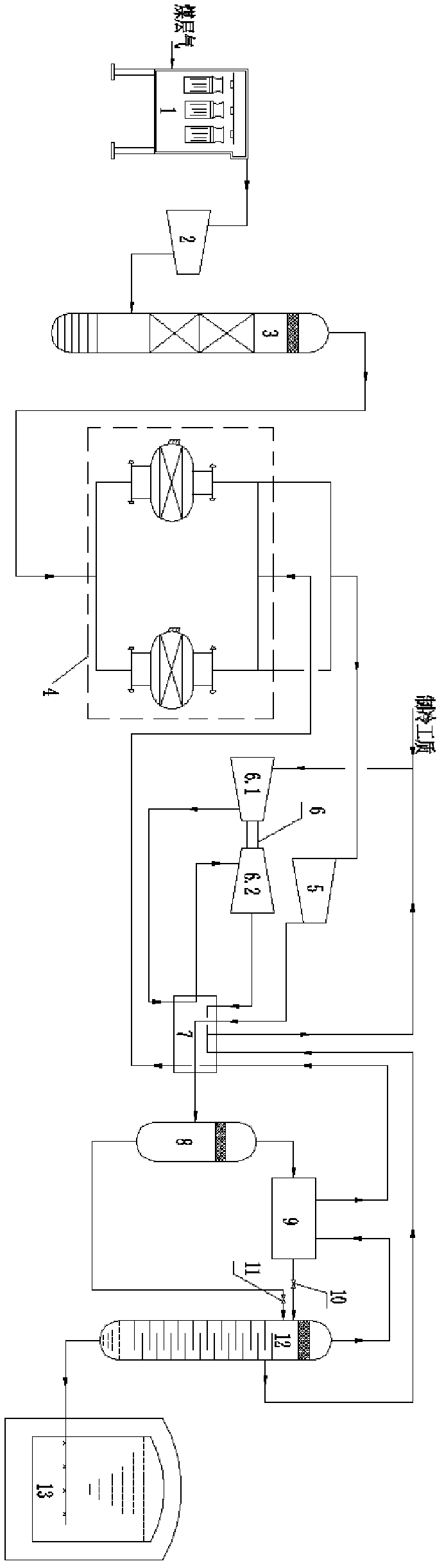

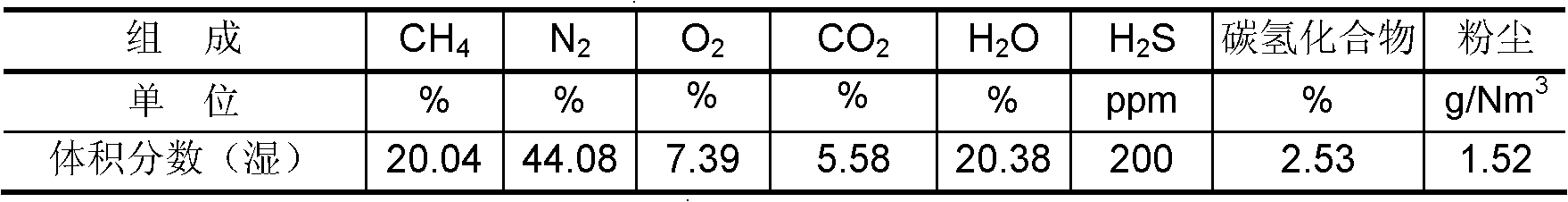

[0037] The coalbed methane (see Table 1 for the composition of coalbed methane) is filtered by the coalbed methane filter 1 to remove large dust particles of 5 to 200 μm, and then pressurized by the coalbed methane compressor 2 to 0.5MPag to 3.0MPag and then enters the washing tower 3, where the coalbed methane is washed In tower 3, the fine dust is removed by countercurrent contact with circulating washing water. After washing, the dust content of coalbed methane is ≤20mg / Nm 3 , and then enter the adsorption system 4 to adsorb and remove impurities such as moisture, carbon dioxide, hydrogen sulfide and hydrocarbons in the coalbed methane, and the regeneration nitrogen in the adsorption system uses the dirty nitrogen circulated by the cryogenic rectification tower 12; As the adsorbent, a renewable and recyclable adsorbent such as molecular sieve or silica gel can be used.

[0038] The purified coalbed methane is introduced into the coalbed methane booster 5 and pressurized to ...

Embodiment 2

[0045] The composition of CBM is shown in Table 2.

[0046] Table 2 Composition of CBM

[0047]

[0048] The process is the same as that in Example 1, and the recovery rate of the finally obtained liquefied natural gas product is 91.8%, and the purity is 96.9% mol.

Embodiment 3

[0050] The composition of CBM is shown in Table 2.

[0051] Table 3 CBM composition

[0052]

[0053] The process is the same as in Example 1, and the recovery rate of the final liquefied natural gas product is 97.5%, and the purity is 99.5% mol.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com