Method for synthesizing cyclohexylamine with aniline by means of gas-phase catalytic hydrogenation

A technology for catalytic hydrogenation and cyclohexylamine, applied in chemical instruments and methods, preparation of organic compounds, preparation of amino compounds, etc. The effect of reducing reactions and ensuring production safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

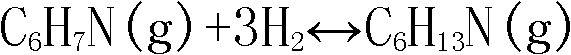

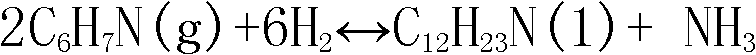

Method used

Image

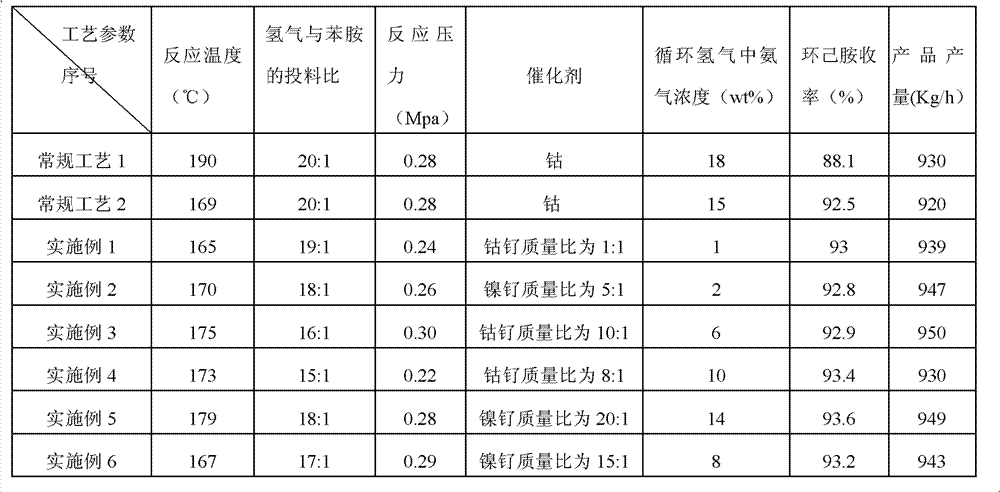

Examples

Embodiment 1

[0027] Mix fresh hydrogen with circulating hydrogen containing 1wt% ammonia, then mix the mixed hydrogen with aniline at a molar ratio of 19:1, and then add it to the aniline evaporator to vaporize the aniline, and the vaporized mixed gas In the fixed-bed hydrogenation reactor pre-installed with the catalyst, the catalytic hydrogenation reaction is carried out under the conditions of 165℃ and 0.24MPa pressure. The materials after the hydrogenation reaction are heat exchanged, condensed and cooled into the separator for gas After separation, crude cyclohexylamine is obtained, which is then rectified to obtain cyclohexylamine product.

[0028] The gas separated in the separator is hydrogen containing ammonia, part of the mixed gas is used as circulating hydrogen, and the other part is continuously vented as tail gas; the step of continuous tail gas venting is to perform online detection of the ammonia concentration of circulating hydrogen Then, according to the detection result, th...

Embodiment 2

[0032] Mix fresh hydrogen with circulating hydrogen containing 2wt% ammonia, then mix the mixed hydrogen with aniline at a molar ratio of 18:1, then add it to the aniline evaporator to vaporize the aniline, and the vaporized mixed gas In a fixed-bed hydrogenation reactor with a pre-installed catalyst, the catalytic hydrogenation reaction is carried out at 170°C and 0.26MPa pressure. After the hydrogenation reaction, the materials after the hydrogenation reaction are subjected to heat exchange, condensation and cooling, and then enter the separator for gas After separation, crude cyclohexylamine is obtained, which is then rectified to obtain cyclohexylamine product.

[0033] The gas separated in the separator is hydrogen containing ammonia, part of the mixed gas is used as circulating hydrogen, and the other part is continuously vented as tail gas; the step of continuous tail gas venting is to perform online detection of the ammonia concentration of circulating hydrogen Then, acco...

Embodiment 3

[0037] Mix fresh hydrogen with circulating hydrogen containing 6wt% ammonia, then mix the mixed hydrogen with aniline at a molar ratio of 16:1, and then add it to the aniline evaporator to vaporize the aniline, and the vaporized mixed gas In the fixed-bed hydrogenation reactor with pre-installed catalyst, the catalytic hydrogenation reaction is carried out under the conditions of 175℃ and 0.3MPa pressure. The materials after the hydrogenation reaction are heat exchanged, condensed and cooled into the separator for gas After separation, crude cyclohexylamine is obtained, which is then rectified to obtain cyclohexylamine product.

[0038] The gas separated in the separator is hydrogen containing ammonia, part of the mixed gas is used as circulating hydrogen, and the other part is continuously vented as tail gas; the step of continuous tail gas venting is to perform online detection of the ammonia concentration of circulating hydrogen Then, according to the detection results, the ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com