Hot knife of waxen image engraving machine

A technique for engraving machines and wax figures, which can be used in decorative arts, processing models, etc., and can solve problems such as inability to process full-dimensional statues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

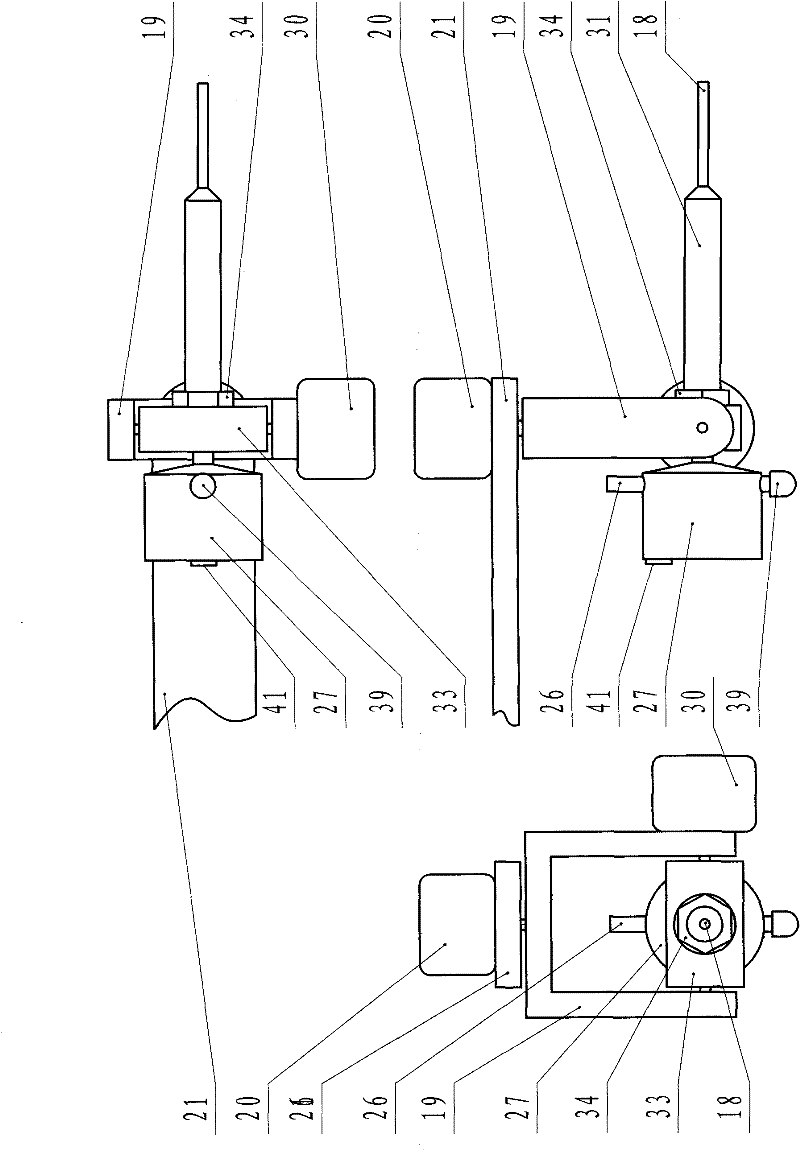

[0021] Below in conjunction with accompanying drawing and embodiment this patent is described further.

[0022] 5.1 Structure

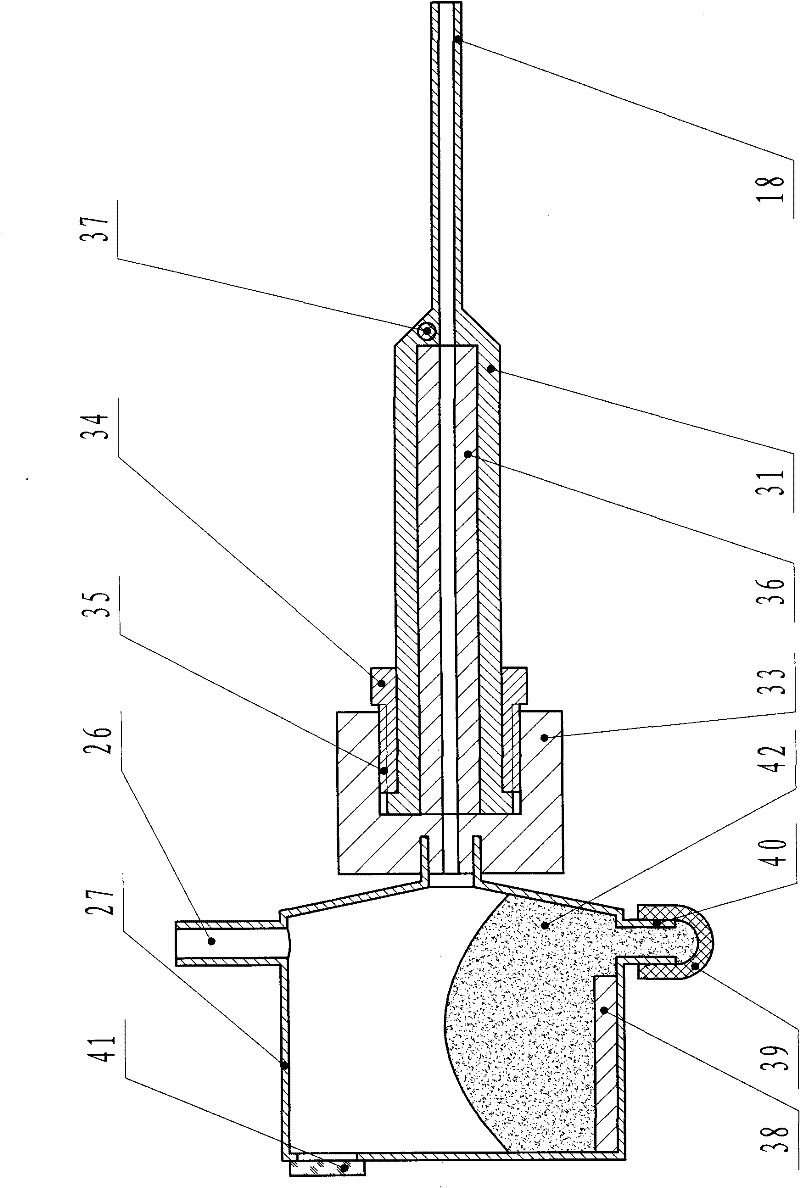

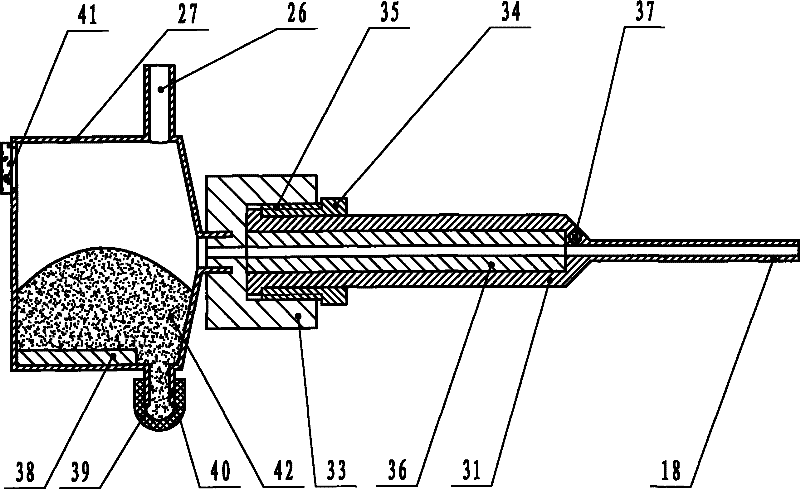

[0023] The hot knife horizontal rotation drive motor (20) is housed on the cantilever (21) end of wax figure engraving machine, and U-shaped support (19) is housed on this motor (20) shaft, and the axle of motor (20) and U-shaped support (19) The axis of symmetry coincides. One side of the U-shaped support (19) is equipped with a hot knife pitching and rotating drive motor (30), and a metal knife rest (33) is vertically fixed on the shaft of this motor (30). The above parts constitute a double-joint manipulator.

[0024] There is a large round hole on the front of the knife seat, and there is a female thread inside to fix the hot knife; there is an annular groove on the back of the knife seat to connect with the waste wax can.

[0025] The hot knife body (31) and the hot knife cutter head (18) are made of copper or copper alloy with good heat condu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com